AI-Powered Manufacturing for the Robotics and Automation

From agile robot prototypes to complete factory automation systems, our AI-driven manufacturing platform provides the full spectrum of services needed to bring your vision to life, faster and more efficiently than ever.

Building an automated system requires a vast range of custom parts, from precise machined components to large fabricated frames. Our AI-powered platform is your single partner for the entire bill of materials. By integrating CNC machining, sheet metal, fabrication, and molding under one AI-managed system, we streamline your supply chain and accelerate your time to market.

One Platform for Your Entire Robotics & Automation System

Our AI platform delivers every component you need to design, build, and scale your robotic and automation solutions, from a single part to a full production line.

Custom Robots & Cobots

Custom Robots & Cobots

Create the core of your system with custom parts for robotic arms, mobile platforms (AMRs), and collaborative robots. We produce high-precision joints, lightweight structural components, and durable housings.

CNC Machining, SLS 3D Printing, Injection Molding

End-of-Arm Tooling (EOAT)

End-of-Arm Tooling (EOAT)

Develop high-performance, application-specific end-effectors. We build everything from delicate soft grippers for pick-and-place to robust metal tooling for welding and material removal.

DMLS (Metal 3D Printing), CNC Machining, Overmolding & LSR

Jigs, Fixtures & Production Tooling

Jigs, Fixtures & Production Tooling

Outfit your automation line with high-precision jigs, fixtures, and nests that are essential for repeatable, high-quality manufacturing. Our in-house tooling capabilities ensure perfect integration.

Tooling and Die Making, CNC Machining, 3D Printing

Frames, Enclosures & Conveyors

Frames, Enclosures & Conveyors

Build the backbone of your automation cell. We manufacture large structural frames, custom machine bases, protective enclosures, and sheet metal components for conveyors and control panels.

Fabrication, Sheet Metal Works, CNC MachiningOur Full Suite of Services for Automation

Quality Assurance

Quality Assurance

Our AI captures your project needs through an intuitive interface, ensuring accuracy from the start.

Automated defect detection

Logistics Coordination

Logistics Coordination

From packaging to delivery the AI optimizes logistics for speed and cost.

Seamless coordination

Why Climate Tech Innovators Choose Wefab AI?

Accelerate Your

Development Cycles

Robotics development is iterative. Our AI-powered platform provides instant quotes and DFM feedback across all manufacturing processes simultaneously. Get your CNC-machined chassis, 3D-printed end-effector, and sheet metal enclosures produced in parallel to drastically reduce your build, test, and redesign cycles.

Simplify Your Complex

Bill of Materials (BOM)

A single robot can have hundreds of unique parts requiring multiple manufacturing processes. Wefab AI is your single partner for the entire BOM. Stop coordinating between machine shops, fabricators, and molders. Upload your complete assembly, and let our platform manage the production and logistics.

Seamlessly Scale from

Prototype to Production

We support your project from the first proof-of-concept to a full production run. Validate your designs with our rapid prototyping services, then seamlessly transition to high-volume manufacturing with our in-house tooling, injection molding, and production CNC capabilities, all on one platform.

Our Full Suite of Services for Robotics & Automation

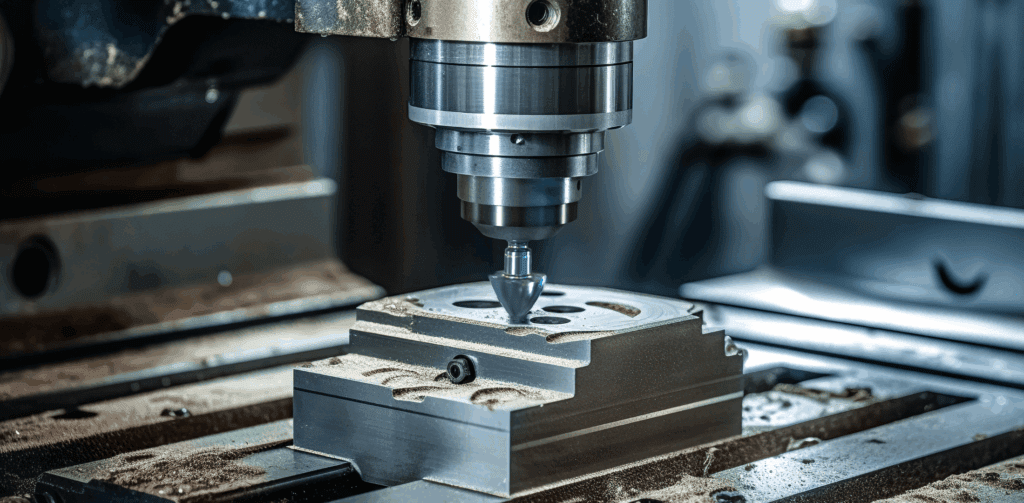

CNC Machining

High-precision milling and turning for critical robotic joints, motor mounts, shafts, and custom machine components from metal and plastic.

- Tolerance: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

- Lead time: Tooling from 4 weeks, parts from 5 business days after approval

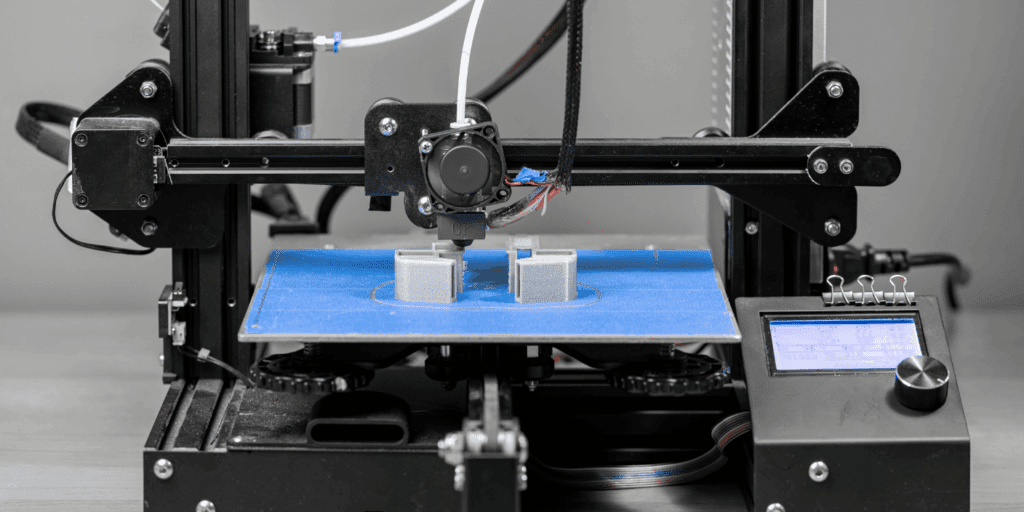

3D Printing

Rapid prototyping and production of complex geometries for custom sensor brackets, EOAT components, and durable nylon housings.

Accuracy: ±0.2% with a lower limit of ±0.05 mm (±0.002″)

- Lead time: Tooling from 4 weeks, parts from 7 business days after approval

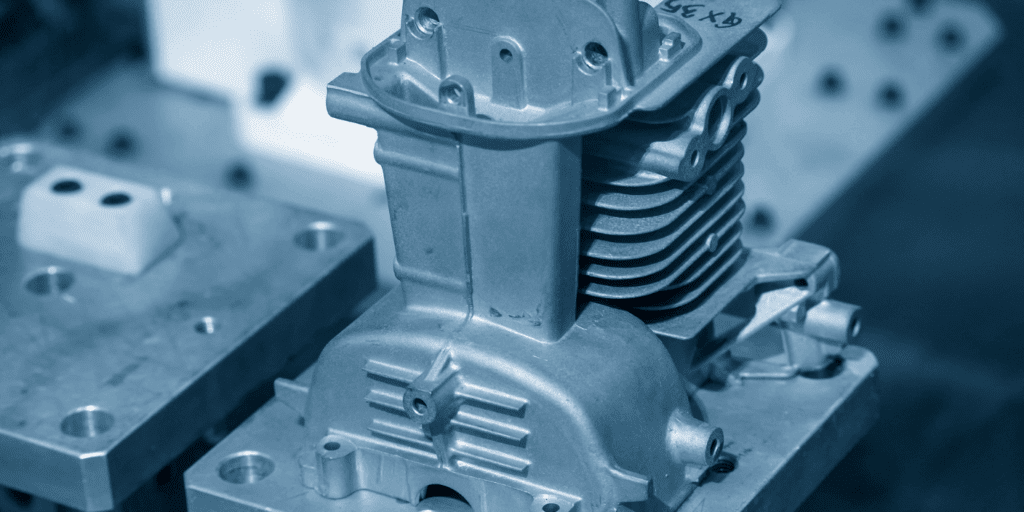

Injection Molding

Scale your production with thousands of identical, low-cost plastic parts for robot shells, internal gears, and product casings.

Tolerance: ±0.3% with a lower limit of ±0.15 mm (±0.006″)

Lead time: From 6 weeks due to multi-material tooling requirements

Sheet Metal Works

Custom-formed brackets, panels, and enclosures for control boxes, electronics chassis, and machine guarding.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

Fabrication

Large-scale structural frames, machine bases, and support weldments for robots and industrial automation systems.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

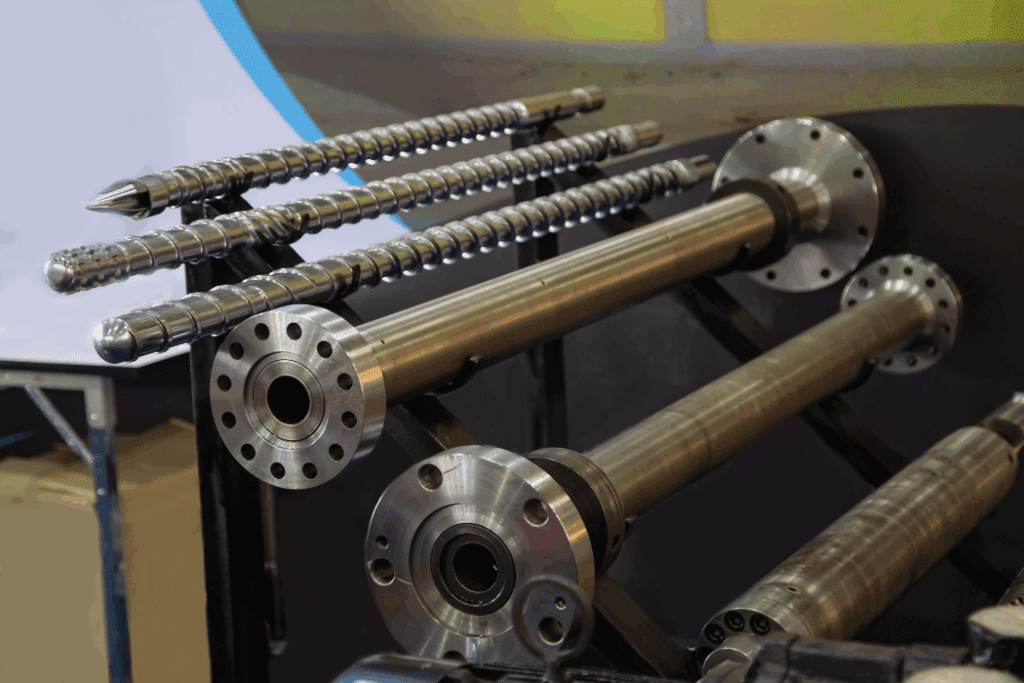

Tooling and Die Making

In-house design and creation of production-grade injection molds, custom dies, and the fixtures needed for your automated line.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

Trusted By Robotics and Industrial Automation Companies

Human Expertise When You Need It

Our expert engineers complement AI capabilities with deep experience in building complex electromechanical systems.

- Design for Manufacturability (DFM) reviews for large, multi-process assemblies.

- Material and process selection to meet the demands of industrial environments.

- Guidance on integrating fabricated, machined, and molded parts into a single system.

- Consultation on transitioning from one-off prototypes to full-scale production.

20+ Years Combined Experience

Meet Our Manufacturing Engineers and Automation Specialists

Our AI-Powered Manufacturing

Platform

Our proprietary AI platform enhances every aspect of the production process with intelligent optimization and real-time adaptability

1,000 Prototypes in 48 Hours

Andrea Martinez

Production Director, EngineeringTech Solutions

30% Faster Integration of an Automated Assembly Cell

“Wefab was our one-stop shop. They delivered the fabricated steel frame, sheet metal control boxes, CNC-machined fixtures, and 3D-printed nests for our robot. The AI platform managed the entire BOM, which cut our supplier coordination time by 80% and got the line running 30% faster.”

Custom Medical Devices

Robert Taylor

Engineering Manager, MechDesign International

Production-Ready Custom Packaging Robot in Record Time

“We needed to scale our new pick-and-place robot. Wefab’s AI platform seamlessly transitioned our design from a prototype to a production-ready system, managing the tooling and die making for our injection molded housings and delivering a flawless first run.”

Ready to Build Your Automated System?

Let our AI-powered platform manage the manufacturing complexities, so you can focus on creating the next generation of robotics and automation.

Common Questions

What's the best way to build a prototype of a custom machine?

For a full system prototype, a multi-process approach is best. Use Fabrication for the main frame, CNC Machining for precise mechanical parts, and 3D Printing for custom brackets and housings. Our platform seamlessly manages all these processes in parallel.

Can you build the frame and the enclosures for my automation system?

Yes. Our Fabrication service is ideal for building large, welded steel and aluminum frames and machine bases. Our Sheet Metal Works service is used to create the precise, custom-formed enclosures, panels, and brackets needed for control systems and guarding.

How do you handle a large BOM with parts from different processes?

Our AI-powered platform is designed for this. You can upload your entire bill of materials, containing parts for CNC, sheet metal, 3D printing, and more. The system provides a single quote, manages production across all services, and consolidates logistics, saving you significant project management time.

Do you make the molds and production tooling in-house?

Yes. Our Tooling and Die Making service is a core part of our production capabilities. We design and manufacture high-quality injection molds, dies, and custom fixtures required to produce your parts at scale.

What materials are best for industrial automation components?

For structural frames, we recommend steel and aluminum (Fabrication). For high-precision mechanical parts, Aluminum 6061-T6 and Stainless Steel (CNC Machining) are excellent. For housings, ABS and Polycarbonate (Injection Molding) and Nylon 12 (3D Printing) are durable choices.