Unlock Precision Custom Parts Manufacturing

From prototyping to small batch production, wefab.ai delivers high-quality custom parts with AI-driven processes.

Revolutionizing Custom Parts Manufacturing Approach

At wefab.ai, we revolutionize custom parts manufacturing by integrating AI-driven insights with advanced methodologies. Our approach ensures precision, efficiency, and transparency at every stage—from design optimization to final delivery.

AI-Powered Design Analysis

Our AI analyzes designs to ensure manufacturability and optimize outcomes.

Iterative Prototyping

We refine your designs through rapid prototyping and feedback loops.

Rigorous Quality Assurance

Real-time AI monitoring ensures every part meets stringent standards.

Transparent Collaboration

Stay informed with milestone tracking and direct team communication.

WeFab’s Custom Parts Custom Parts Manufacturing Services

Wefab.ai specializes in rapid prototyping, small batch production, and design optimization, powered by AI.

Prototyping

Create rapid, functional, or appearance prototypes to test designs.

- Rapid Prototyping

- Functional Prototypes

- Appearance Models

- Testing Prototypes

- Iteration Process

Batch Manufacturing

Create rapid, functional, or appearance prototypes to test designs.

- Volume Capabilities

- Scaling Strategies

- Cost Optimization

- Lead Time Management

- Batch Quality Control

Design Services

Optimize designs for manufacturability with expert analysis.

- Design Review

- Manufacturability Analysis

- Design Optimization

- Material Suggestions

- Cost Reduction Strategies

AI-Powered Design to Delivery

Experience a seamless process from design to delivery with AI optimization.

- Rapid AI-driven design validation

- Real-time adjustments

- Automated quality checks

- Efficient delivery scheduling

Diverse Range of Manufacturing Capabilities

Wefab.ai specializes in rapid prototyping, small batch production, and design optimization, powered by AI.

3D

Printing

Rapidly prototype and produce complex geometries with high precision.

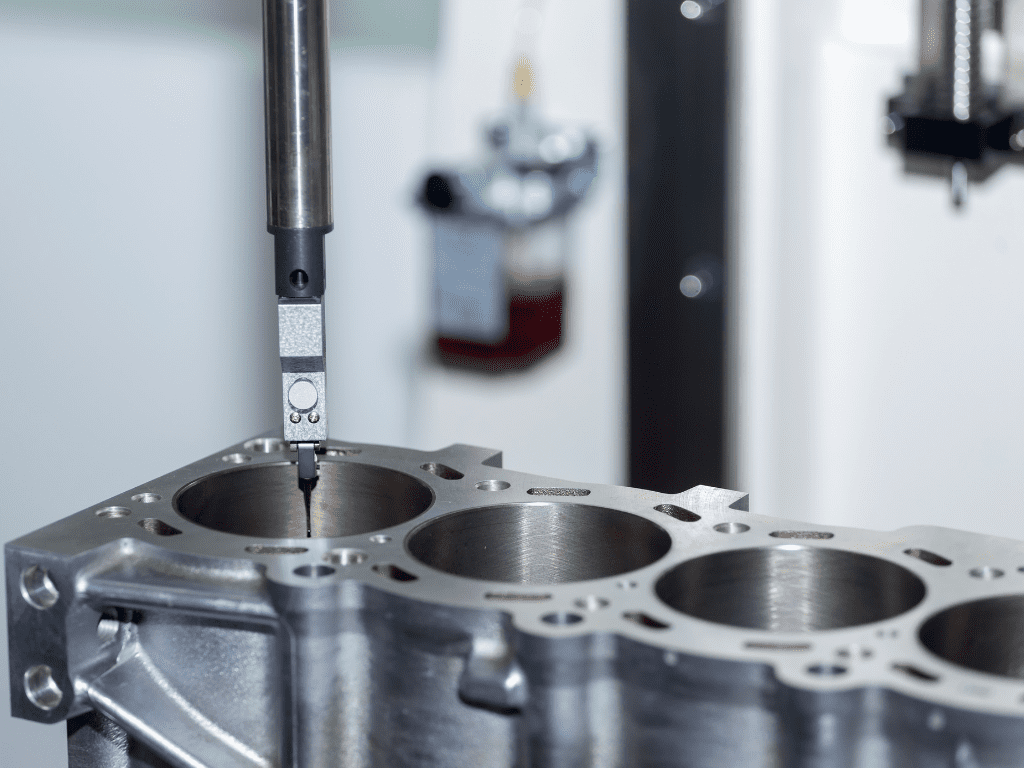

CNC

Machining

Achieve tight tolerances and superior finishes for metal and plastic parts.

Sheet Metal

Works

Fabricate durable metal components with custom applications, high durability, flexibility

Fabrication

Custom assemblies for specialized manufacturing needs.

Tool &

Die Making

Precision tools for manufacturing processes.

Materials and Technology

Explore the materials and technologies we use to deliver high-quality custom parts tailored to your needs.

3D Printing Materials

Choose from a range of materials like PLA, ABS, PETG, and titanium for prototyping and production.

- PLA

- ABS

- PETG

- Titanium

- Nylon

CNC Materials

We machine parts from metals like aluminum, steel, and titanium, as well as plastics like PEEK and Delrin.

- Aluminum

- Steel

- Titanium

- Peek

- Delrin

Injection Molding Resins

Select from resins like ABS, polycarbonate, and nylon for durable, high-volume parts.

- ABS

- Polycarbonate

- Nylon

- Polypropylene

- TPE

Sheet Metal

Work with materials like stainless steel, aluminum, and copper for robust, custom metal parts.

- Stainless Steel

- Aluminum

- Copper

- Brass

- Galvanized Steel

Our AI-Powered Manufacturing Platform

Our AI platform is the backbone of our custom parts manufacturing, enhancing every stage from design to delivery.

Intelligent Design and Planning

Intelligent Design and Planning

Our AI analyzes your designs and project requirements to create the optimal manufacturing plans.

- Automated design analysis to ensure manufacturability

- Precise cost estimation based on materials and processes

- Material and process recommendations for efficiency

- Simulation of production outcomes to minimize risks

- Optimization suggestions to improve quality and reduce costs

Real-Time Monitoring and Adjustment

Real-Time Monitoring and Adjustment

Our AI platform continuously tracks and adapts the manufacturing process to ensure success.

- Real-time status updates on prototyping and production

- Early detection of potential issues or delays

- Adaptive scheduling to maintain project timelines

- Dynamic resource allocation to address constraints

- Predictive analytics to prevent quality or performance issues

Unmatched Visibility and Collaboration

Unmatched Visibility and Collaboration

We provide complete transparency into your custom parts

project.

- Secure client portal with real-time progress updates

- Comprehensive documentation and reporting

- Direct communication with your project team

- Milestone tracking and notifications

- Detailed project history and analytics

Optimized Manufacturing Through TOC & CCPM

Our methodology for minimizing delays and maximizing output!

Design Optimization Expertise

Streamlined Design for Manufacturability

We optimize designs with DFMA to reduce complexity and enhance production efficiency.

Proactive Risk Mitigation

FMEA identifies potential design and process risks, ensuring reliable parts.

Simplified Assembly Processes

DFMA minimizes assembly time and costs by refining part designs.

Enhanced Reliability Standards

FMEA ensures compliance with industry standards through rigorous risk analysis.

Tangible Benefits

Faster Time-to-Market

Streamlined designs and risk mitigation reduce production delays.

Cost Efficiency

Simplified designs and fewer parts lower manufacturing and assembly costs.

Improved Part Quality

Better equipment and labor utilization across production

Enhanced Production Reliability

Optimized processes lead to consistent, high-quality outcomes.

Why We Are Best in Custom Manufacturing

Our expertise in advanced methodologies sets us apart in delivering superior custom parts.

Product Optimization Expertise

Theory of Constraints (TOC)

Strategic management to identify and resolve bottlenecks in our supply chain.

Critical Chain Project Management (CCPM)

Advanced project management to optimize scheduling and resource allocation.

Design for Manufacturing & Assembly (DFMA)

Systematic optimization of design and assembly processes to enhance production efficiency.

Failure Mode & Effects Analysis (FMEA)

Critical analysis to identify and mitigate risks, ensuring reliable outcomes.

AI-Powered Execution

Intelligent Constraint Detection

AI identifies bottlenecks missed in manual analysis for optimized production.

Predictive Quality Systems

ML models predict potential quality issues before occurrence, ensuring consistency.

Dynamic Resource Allocation

AI adjusts resource allocation based on production conditions for efficiency.

Real-Time Optimization

Continuous adjustments enhance production outcomes in real time.

How We Execute Contract Manufacturing

Our process combines systematic methodology with AI-enhanced execution

1

Discovery & Assessment

Thorough analysis of product requirements, specifications, and potential risks.

2

Manufacturing Strategy

Comprehensive strategy development including process selection and resource planning.

3

AI-Optimized Planning

Optimized production planning using Theory of Constraints and Critical Chain principles.

4

Execution & Monitoring

Rigorous control with real-time monitoring and AI-driven adjustments.

5

Continuous Improvement

Rigorous control with real-time monitoring and AI-driven adjustments.

Industries

We Serve

Climate Tech

Precision components for sustainable energy systems, carbon capture technologies, and environmental monitoring.

Electric Vehicles

Critical components for EV powertrains, battery systems, charging infrastructure, and control electronics.

Robotics & Automation

Specialized parts for robotic systems, sensor arrays, control mechanisms, and automation equipment.

Consumer Hardware

Precision parts for consumer devices, IoT products, and innovative hardware solutions.

Real-World Success Stories

Discover how wefab.ai has helped clients achieve their manufacturing goals through innovative solutions.

3D-Printed Prototype for Climate Tech

John Smith

Climate Tech Innovator

We delivered a 3D-printed prototype for a solar panel component, enabling rapid testing and iteration.

“wefab.ai’s 3D printing accelerated our development cycle by weeks!”

CNC-Machined EV Part

Sarah Johnson

EV Manufacturer

A precision CNC-machined aluminum part for an electric vehicle battery housing, meeting tight tolerances.

“The quality and precision of wefab.ai’s CNC machining exceeded our expectations.”

Injection-Molded Robotics Component

Sarah Johnson

Robotics Engineer

We produced a high-volume batch of injection-molded nylon parts for a robotics application, ensuring durability.

“wefab.ai’s injection molding delivered consistent quality for our robotics project.”

Getting Started with wefab.ai

See how wefab.ai has helped innovators bring their ideas to life with our advanced manufacturing capabilities.

Request a Quote

Book a Consultation

Schedule a free consultation with our experts to discuss your project. We’ll help you understand the best manufacturing approach for your needs and provide guidance on materials, processes, and timelines.