AI-Powered Production 3D Printing for High-Volume Manufacturing and End-Use Parts

Our AI manages every step of the production 3D printing or additive manufacturing process, delivering scalable component batches faster and more efficiently than ever.

“Our AI-powered platform takes full control of your production 3D printing projects, acting as your dedicated Single Point of Contact. From optimizing build parameters to ensuring batch-to-batch consistency, our AI works 24/7 to deliver production-grade components on time and within budget.”

TheAI-Driven Process

Requirement Capturing

Our AI captures your project specifications through an intuitive interface, ensuring material selection, production volumes, and quality control requirements are understood from the start.

Automatic production analysis and manufacturing parameter selection

Technology & Material Selection

Our AI selects the optimal production technology—MJF, SLS, DMLS, or high-throughput FDM—based on part geometry, volume requirements, and performance specifications.

Intelligent material selection and batch processing optimization

Design for Scalability

The AI optimizes your design for production manufacturing, analyzing features for repeatability, process stability, and potential batch variations.

Real-time DFM with production yield analysis and quality control planning

Project Monitoring

Track production operations in real-time with AI-powered updates on batch progress, statistical process control, and part-to-part consistency.

Live monitoring of production metrics and statistical quality indicators

Follow-ups & Reporting

Stay informed with automated follow-ups and detailed reports on production yield, statistical quality control, and material lot traceability.

Comprehensive batch completion documentation

Quality Assurance

AI coordinates statistical sampling, material testing, and dimensional verification, ensuring batches meet specifications with consistent properties.

Automated SPC reporting and production quality validation

Risk Analysis

The AI identifies production risks like material lot variations, machine calibration drift, or post-processing inconsistencies and implements compensating strategies proactively.

Predictive maintenance scheduling and statistical process control optimization

Logistics Coordination

From post-processing and secondary operations to inventory management and delivery, the AI optimizes the production workflow for speed and cost.

Seamless coordination of manufacturing operations

Why Choose Our

AI Platform

Working with a manufacturing partner who understands your hardware needs makes all the difference.

24/7 Production Capability

Our AI never sleeps, managing your manufacturing projects across multiple machines and production cells.

Unmatched Scalability

Optimized batch processing and intelligent production planning mean seamless scaling from prototypes to high-volume manufacturing.

Exceptional Consistency

AI compensates for process variations and material differences, delivering consistent part quality across production runs.

Cost-Effective Manufacturing

Smart capacity utilization, optimized material management, and streamlined workflows offer competitive pricing.

Proactive Solutions

Process drift, material inconsistencies, and equipment variations are detected and addressed before they affect production quality.

Human Expertise When You Need It

Our experts complement AI capabilities with specialized knowledge and hands-on experience

Complex project consultation and custom solutions design

Technical support for specialized materials and finishing requirements

Quality assurance reviews for critical applications

On-deman engineering support and design optimization

Meet Our Production Specialists and Manufacturing Engineers

20+ Years Combined Experience

Proven Results

James Wilson

Supply Chain Director, IndustrialTech Solutions

75% faster production on end-use components

The AI-driven production process transformed our supply chain. The intelligent batch optimization and adaptive manufacturing parameters delivered consistent components at unprecedented volumes, accelerating our product launch timeline.

Dr. Emma Rodriguez

Manufacturing Manager, AutoInnovate International

99.7% first-pass yield rate on production runs

The reliability and consistency we’ve achieved with Wefab.ai’s production 3D printing platform have been crucial for our automotive components. The AI’s ability to maintain tight tolerances across high volumes has dramatically improved our manufacturing efficiency.

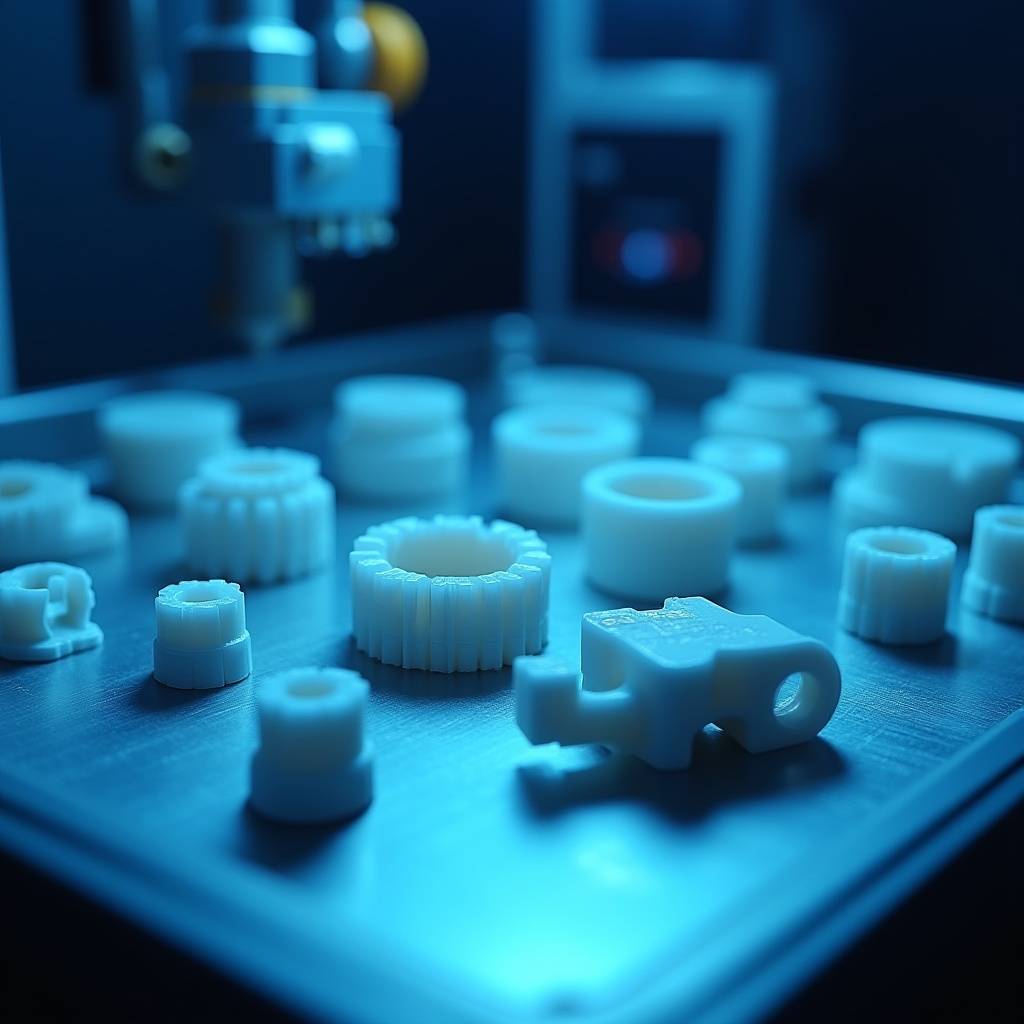

3d Printing Capabilities

Plastic 3D Printing Service

Quick and cost-effective 3D printing solutions

- Precision level: ±0.5% with a minimum of 0.6 mm

- Turnaround: Starting from 2 business days

Learn More: See our Plastic 3D Printing Services

FDM 3D Printing

Efficient and budget-friendly prototyping

- Accuracy: ±0.5% with a minimum of 0.5 mm

- Delivery: As fast as 1 business day

Learn More: See our FDM Services

Multi Jet Fusion

Robust prototyping and small-batch production

- Precision: ±0.3% with a minimum of 0.3 mm

- Lead time: From 2 business days

Learn More: See our MJF Services

SLS 3D Printing

Durable and versatile printing options

- Tolerance: ±0.3% with a minimum of 0.4 mm

- Processing time: Starting from 3 business days

Learn More: See our SLS Services

Stereolithography - SLA 3D Printing

High-detail visual prototyping

- Accuracy: ±0.3% with a minimum of 0.3 mm

- Turnaround: From 2 business days

Learn More: See our SLA Services

PolyJet 3D Printing

Precise and multi-material printing

- Dimensional accuracy: ±0.2% with a minimum of 0.2 mm

- Delivery: Starting from 2 business days

Learn More: See our PolyJet Services

Carbon DLS

Fast and flexible production-grade parts

- Precision: ±0.4% with a minimum of 0.5 mm

- Lead time: From 3 business days

Learn More: See our Carbon DLS Services

Metal 3D Printing Service

High-strength metal part fabrication

- Tolerance: ±0.3% with a minimum of 0.4 mm

- Turnaround: Starting from 4 business days

Learn More: See our Metal 3D Printing Services

Direct Metal Laser Sintering

Advanced metal prototyping and production

- Accuracy: ±0.3% with a minimum of 0.3 mm

- Delivery: From 5 business days

Learn More: See our DMLS Services

Metal Binder Jetting

Cost-effective metal part creation

- Precision: ±0.4% with a minimum of 0.5 mm

- Lead time: Starting from 4 business days

Learn More: See our Metal Binder Jetting Services

Frequently Asked Questions

How does AI improve the production 3D printing process?

Our AI optimizes batch configuration, process parameters, and quality control protocols, reducing manufacturing time and enhancing part consistency. It continuously learns from production data to minimize variations and predict optimal manufacturing settings for repeatable results.

What technologies do you use for production 3D printing?

We employ Multi Jet Fusion, Selective Laser Sintering, Direct Metal Laser Sintering, and high-throughput FDM systems optimized for production volumes. Our AI automatically selects the most appropriate technology based on your part requirements, volumes, and material specifications.

What are your typical lead times for production 3D printed parts?

Initial production runs can be completed in 7-10 days, with subsequent batches available in 5-7 business days. For ongoing production, we establish JIT manufacturing protocols with scheduled delivery windows aligned to your inventory requirements.

How do you ensure consistent quality in high-volume production?

Our AI employs Statistical Process Control (SPC), automated inspection systems, and batch sampling protocols. Production runs undergo rigorous quality assurance with capability for maintaining Cpk values above 1.33 on critical features, ensuring consistent part-to-part quality.

What production volumes can you handle with 3D printing?

We routinely process production runs from 100 to 10,000+ units with consistent quality and competitive pricing. Our AI-driven capacity planning enables seamless scaling from prototype volumes to full production, with logistics coordination for inventory management.

Ready to experience the future of production 3D printing?

Let our AI work for you and transform your manufacturing process with intelligent production strategies and unmatched batch consistency.