Liquid Silicone Rubber (LSR) Molding for High-Performance Parts

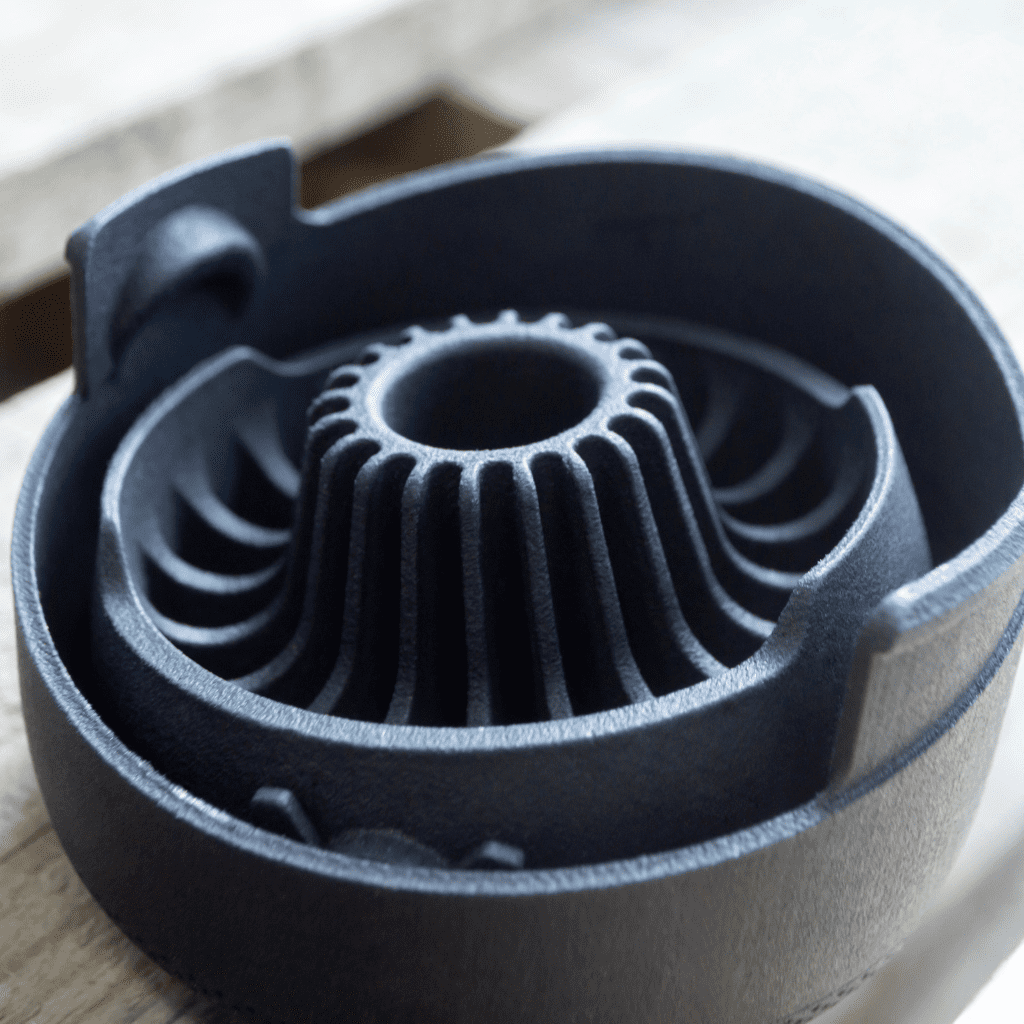

Wefab AI masters the unique thermoset process of LSR molding, delivering exceptionally durable, flexible, and biocompatible silicone components with remarkable precision.

“Our AI-powered platform takes full control of your Liquid Silicone Rubber (LSR) molding projects, acting as your dedicated Single Point of Contact. From precisely managing the two-part mixing ratio to optimizing cure times in a heated mold, our AI works 24/7 to produce flawless silicone parts for the most demanding applications.”

End-to-End Production Management

Click a stage to see how we help

Requirement Capturing

STEP 1

Part & Mold Design Analysis (DFM)

STEP 2

Tooling & Material Selection

STEP 3

Project Monitoring

STEP 4

Follow-ups & Reporting

STEP 5

Risk Analysis

STEP 6

Quality Assurance

STEP 7

Logistics Coordination

STEP 8

Our AI captures your project specifications, ensuring critical properties like durometer (hardness), color, and required certifications are defined from the start.

Material grade, durometer, and certification selection

The AI analyzes your CAD model for manufacturability with low-viscosity LSR, optimizing for features like thin walls and complex details while designing tooling with precise shutoffs to prevent flash.

Automated DFM for flash prevention and thin-wall geometry

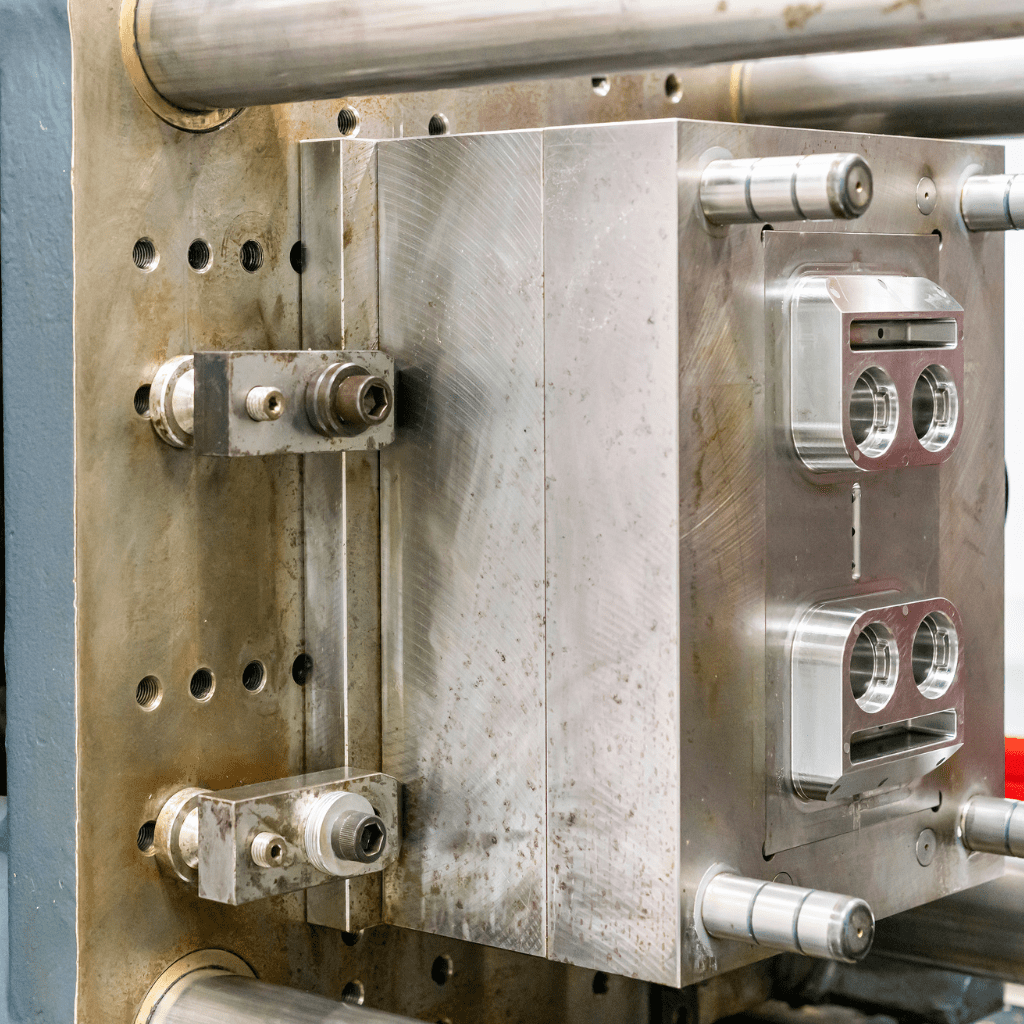

Our AI designs high-precision tooling with cold-runner systems to keep the material cool before injection and ensures the two-part LSR system is selected for your specific performance needs.

Intelligent tooling design with cold-runner optimization

Track the thermoset molding operation in real-time, with AI-powered updates on the A:B mix ratio, mold temperature, injection pressure, and curing time to ensure consistent part properties.

Live monitoring of mix ratio, mold temperature, and cure cycle

Stay informed with automated follow-ups and detailed reports on material lot traceability, process validation, and dimensional inspection, with special attention to flash-free part quality.

Comprehensive FAI with cure validation and flash inspection

The AI proactively identifies LSR molding risks like flash, air traps, or incomplete curing, and implements compensating process strategies before defects occur.

Predictive flash control and cure cycle optimization

AI coordinates high-resolution visual inspection to ensure every part is free from flash and meets all dimensional and cosmetic specifications.

Automated flash detection and dimensional validation

From robotic part removal and post-curing to custom packaging and delivery, the AI optimizes the entire post-molding workflow for speed and cleanliness.

Seamless coordination of post-curing and cleanroom packaging

End-to-End Production Management

Click a stage to see how we help

Requirement Capturing

STEP 1

Our AI captures your project specifications, ensuring critical properties like durometer (hardness), color, and required certifications are defined from the start.

Material grade, durometer, and certification selection

Part & Mold Design Analysis (DFM)

STEP 2

The AI analyzes your CAD model for manufacturability with low-viscosity LSR, optimizing for features like thin walls and complex details while designing tooling with precise shutoffs to prevent flash.

Automated DFM for flash prevention and thin-wall geometry

Tooling & Material Selection

STEP 3

Our AI designs high-precision tooling with cold-runner systems to keep the material cool before injection and ensures the two-part LSR system is selected for your specific performance needs.

Intelligent tooling design with cold-runner optimization

Project Monitoring

STEP 4

Track the thermoset molding operation in real-time, with AI-powered updates on the A:B mix ratio, mold temperature, injection pressure, and curing time to ensure consistent part properties.

Live monitoring of mix ratio, mold temperature, and cure cycle

Follow-ups & Reporting

STEP 5

Stay informed with automated follow-ups and detailed reports on material lot traceability, process validation, and dimensional inspection, with special attention to flash-free part quality.

Comprehensive FAI with cure validation and flash inspection

Risk Analysis

STEP 6

The AI proactively identifies LSR molding risks like flash, air traps, or incomplete curing, and implements compensating process strategies before defects occur.

Predictive flash control and cure cycle optimization

Quality Assurance

STEP 7

AI coordinates high-resolution visual inspection to ensure every part is free from flash and meets all dimensional and cosmetic specifications.

Automated flash detection and dimensional validation

Logistics Coordination

STEP 8

From robotic part removal and post-curing to custom packaging and delivery, the AI optimizes the entire post-molding workflow for speed and cleanliness.

Seamless coordination of post-curing and cleanroom packaging

Common Overmolding Material Combinations

Wefab AI is equipped to mold nearly any commercially available thermoplastic pairing. Our AI ensures we select materials with ideal chemical compatibility for a robust, permanent bond. Some of the most common combinations include:

Rigid Substrate Material

ABS

Polycarbonate (PC)

PC/ABS

Nylon (PA)

Polypropylene (PP)

Engineering Plastics

TPE, TPU

TPE, TPU, Silicone (LSR)

TPE, TPU

TPE

TPE (specially formulated)

Why Choose Our

AI Platform

24/7 Production Capability

Our AI never sleeps, managing your injection molding projects across multiple presses and materials for continuous production.

Superior Biocompatibility & Purity

Our AI-controlled, clean process is ideal for producing medical and food-grade components that require high purity and meet stringent regulatory standards.

Extreme Temperature Resistance

LSR parts perform reliably in harsh environments, maintaining their properties in temperatures ranging from -65°C to 200°C (-85°F to 392°F).

Complex Geometries & Thin Walls

The low viscosity of LSR, managed by our AI, allows for the creation of intricate, complex parts with extremely thin walls that are impossible to achieve with other elastomers.

Flash-Free Precision

AI-assisted tooling design and real-time process control minimize or eliminate flash, producing clean, ready-to-use parts directly from the mold.

Human Expertise When You Need It

Our expert mold makers and thermoset engineers complement AI capabilities with specialized knowledge in LSR molding.

- Complex project consultation and precision tool design for flash control

- Technical support for medical-grade (USP Class VI) and optical LSR materials

- Quality assurance reviews for critical healthcare and automotive safety applications

- On-demand engineering support for optimizing parts for the LSR process

Meet Our Certified Mold Makers and LSR Process Specialists

20+ Years Combined Experience

Injection Molding Capabilities

| Feature | Specification |

|---|---|

| Process Types | Liquid Silicone Rubber (LSR) Molding, LSR Overmolding |

| Material Grades | Medical (USP Class VI, ISO 10993), Food Grade (FDA 21 CFR 177.2600), Optical |

| Durometer Range | 10 Shore A to 80 Shore A |

| Mold Types | High-strength Steel Tooling (P20, H13, S7) with precision cold-runner systems |

| Quality Control | Automated visual inspection for flash, CMM for critical dimensions |

| Secondary | Post-curing for enhanced material properties, custom color |

| Operations | matching |

Proven Results

Samantha Lee

Senior Product Engineer, Innovate Electronics

60% reduction in cycle time on consumer electronic enclosures

The AI platform’s process window optimization was a game-changer. It delivered consistently flawless ABS parts at a speed we couldn’t achieve manually, dramatically increasing our throughput.

David Chen

Engineering Director, Precision Auto Systems

99.9% first-time-right on critical-tolerance automotive gears

The reliability is astounding. The AI’s ability to run mold flow analysis and apply predictive quality control ensured our PEEK gears met stringent performance specs from the very first shot. It saved us weeks of trial and error.

Injection Molding Capabilities

Plastic Injection Molding

High-volume production of complex and durable thermoplastic parts.

- Tolerance: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

- Lead time: Tooling from 4 weeks, parts from 5 business days after approval

Insert Molding

Molding thermoplastics around metal components for enhanced strength and reliability.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

Overmolding

Creating multi-material parts with soft-touch grips and enhanced ergonomics.

Tolerance: ±0.3% with a lower limit of ±0.15 mm (±0.006″)

Lead time: From 6 weeks due to multi-material tooling requirements

Ready to produce flexible, high-performance silicone parts?

Let our AI eliminate the complexities of LSR molding and deliver clean, precise, and durable components for your most demanding applications.

Frequently Asked Questions

How does AI improve the LSR molding process?

Our AI is essential for precisely controlling the 1:1 mix ratio of the two-part LSR system and managing the heated mold to ensure a complete, uniform cure. It also helps design extremely precise tooling and uses real-time pressure monitoring to prevent flash.

What is the difference between Liquid Silicone Rubber (LSR) and TPE?

LSR is a thermoset material that is chemically cross-linked with heat for a permanent, stable structure with excellent temperature resistance. TPE (Thermoplastic Elastomer) is a thermoplastic that can be re-melted and re-formed, offering good flexibility but with a lower temperature range and different chemical properties.

How do you prevent flash on LSR parts?

Preventing flash requires a combination of AI-assisted tool design with extremely tight tolerances (often within 0.005 mm), precisely controlled injection pressure, and real-time process monitoring to manage the low-viscosity material flow.

Is LSR safe for medical applications?

Yes. We offer medical-grade LSR that complies with stringent biocompatibility standards like USP Class VI and ISO 10993. The material is hypoallergenic, can be sterilized, and is ideal for skin-contact and implantable devices.

What file formats do you accept for LSR molding projects?

We accept STEP, STP, IGES, IGS, X_T, and other standard 3D model formats. Our AI will automatically analyze your design for manufacturability (DFM), paying special attention to the unique requirements of the LSR molding process.