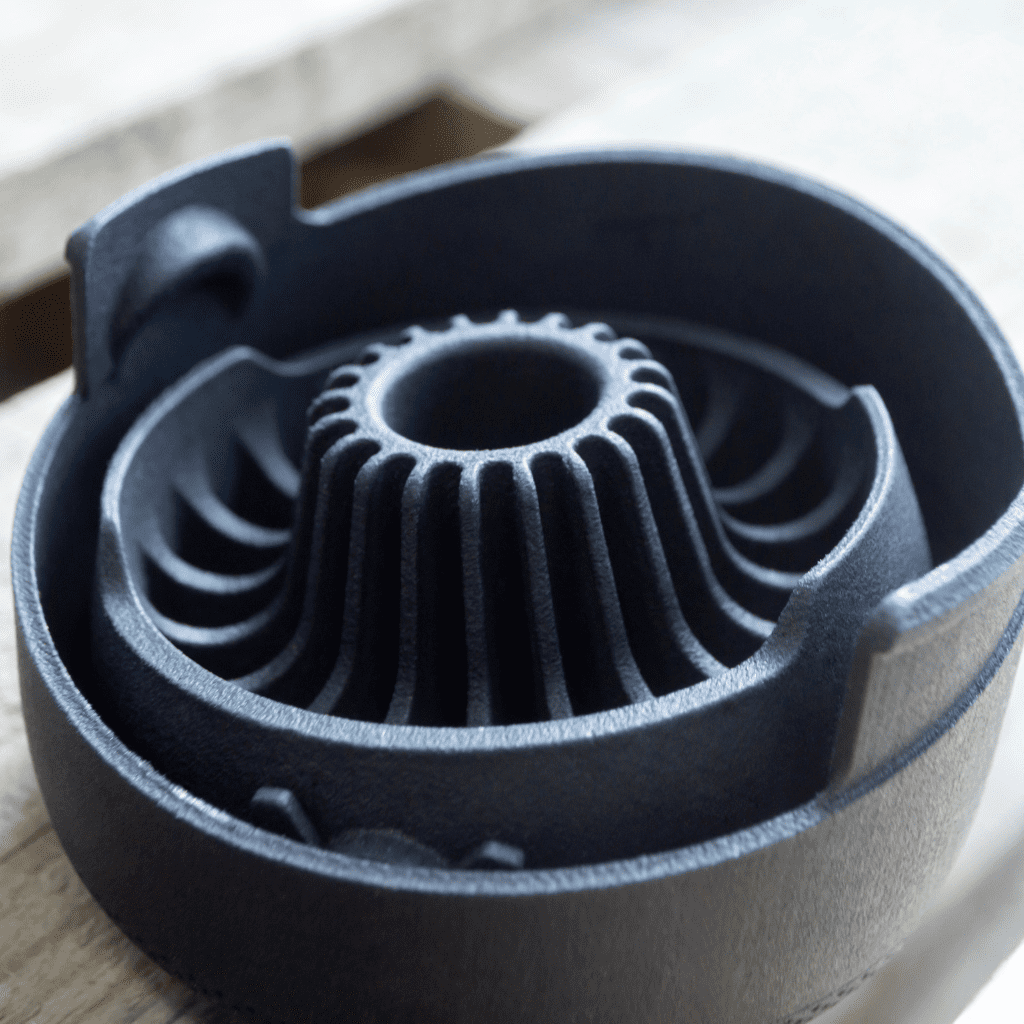

Insert Molding Services for Robust, Integrated Components

Our AI platform precisely manages the insert molding process, seamlessly combining the strength of metal components with the design versatility of high-performance thermoplastics.

“Our AI-powered platform takes full control of your insert molding projects, acting as your dedicated Single Point of Contact. From robotic insert placement to controlling melt flow around delicate components, our AI ensures flawless encapsulation and superior part strength, eliminating costly and unreliable secondary assembly steps.”

End-to-End Production Management

Click a stage to see how we help

Requirement Capturing

STEP 1

Part & Mold Design Analysis (DFM)

STEP 2

Tooling & Automation Strategy

STEP 3

Project Monitoring

STEP 4

Follow-ups & Reporting

STEP 5

Risk Analysis

STEP 6

Quality Assurance

STEP 7

Logistics Coordination

STEP 8

Our AI captures your project specifications for both the thermoplastic resin and the insert component, ensuring performance requirements like pull-out strength, conductivity, and tolerances are understood from the start.

Plastic and insert material specification

The AI analyzes your CAD model to optimize plastic flow around the insert, preventing voids or damage. It also provides feedback on insert design features like knurling and undercuts to maximize anchoring strength.

Automated DFM for insert encapsulation and anchoring

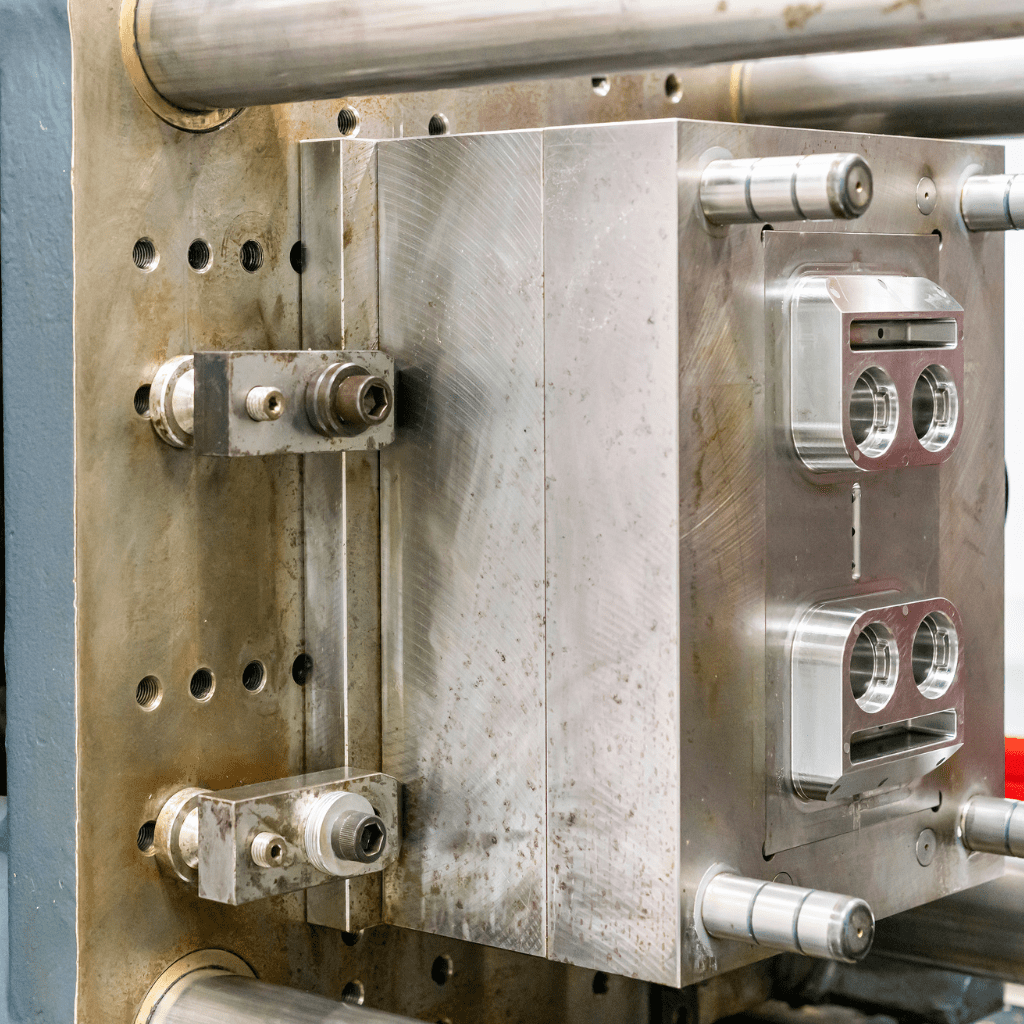

Our AI designs robust tooling with precise features (pins, magnets, or custom shutoffs) to securely hold the insert during high-pressure injection. It also determines the optimal loading strategy, from manual placement to high-speed robotic automation.

Intelligent mold design and insert loading strategy (manual vs. robotic)

Track the molding operation in real-time, with AI-powered updates on insert placement accuracy, injection pressure, and melt temperature to prevent insert shifting or damage.

Live monitoring of insert position and process parameters

Stay informed with automated follow-ups and detailed reports on material lot traceability, process validation, and dimensional inspection, including verification of insert position and integrity.

Comprehensive FAI with insert positional and functional validation

The AI proactively identifies insert molding risks like insert shifting, flash onto the insert, or incomplete encapsulation, and implements compensating process strategies before defects occur.

Predictive insert shift control and melt flow optimization

AI coordinates CMM inspection and automated visual inspection to ensure every part meets dimensional specs and that the insert is correctly positioned, clean, and fully functional.

Automated dimensional validation and insert integrity checks

From part ejection and inspection to custom packaging and delivery, the AI optimizes the entire post-molding workflow for speed and cost-efficiency.

Seamless coordination of post-molding assembly and testing

End-to-End Production Management

Click a stage to see how we help

Requirement Capturing

STEP 1

Our AI captures your project specifications for both the thermoplastic resin and the insert component, ensuring performance requirements like pull-out strength, conductivity, and tolerances are understood from the start.

Plastic and insert material specification

Part & Mold Design Analysis (DFM)

STEP 2

The AI analyzes your CAD model to optimize plastic flow around the insert, preventing voids or damage. It also provides feedback on insert design features like knurling and undercuts to maximize anchoring strength.

Automated DFM for insert encapsulation and anchoring

Tooling & Material Selection

STEP 3

Our AI designs robust tooling with precise features (pins, magnets, or custom shutoffs) to securely hold the insert during high-pressure injection. It also determines the optimal loading strategy, from manual placement to high-speed robotic automation.

Intelligent mold design and insert loading strategy (manual vs. robotic)

Project Monitoring

STEP 4

Track the molding operation in real-time, with AI-powered updates on insert placement accuracy, injection pressure, and melt temperature to prevent insert shifting or damage.

Live monitoring of insert position and process parameters

Follow-ups & Reporting

STEP 5

Stay informed with automated follow-ups and detailed reports on material lot traceability, process validation, and dimensional inspection, including verification of insert position and integrity.

Comprehensive FAI with insert positional and functional validation

Risk Analysis

STEP 6

The AI proactively identifies insert molding risks like insert shifting, flash onto the insert, or incomplete encapsulation, and implements compensating process strategies before defects occur.

Predictive insert shift control and melt flow optimization

Quality Assurance

STEP 7

AI coordinates CMM inspection and automated visual inspection to ensure every part meets dimensional specs and that the insert is correctly positioned, clean, and fully functional.

Automated dimensional validation and insert integrity checks

Logistics Coordination

STEP 8

From part ejection and inspection to custom packaging and delivery, the AI optimizes the entire post-molding workflow for speed and cost-efficiency.

Seamless coordination of post-molding assembly and testing

Common Overmolding Material Combinations

Wefab AI is equipped to mold nearly any commercially available thermoplastic pairing. Our AI ensures we select materials with ideal chemical compatibility for a robust, permanent bond. Some of the most common combinations include:

Rigid Substrate Material

ABS

Polycarbonate (PC)

PC/ABS

Nylon (PA)

Polypropylene (PP)

Engineering Plastics

TPE, TPU

TPE, TPU, Silicone (LSR)

TPE, TPU

TPE

TPE (specially formulated)

Why Choose Our

AI Platform

24/7 Production Capability

Our AI never sleeps, managing your injection molding projects across multiple presses and materials for continuous production.

Eliminate Secondary Assembly

Integrate metal components directly into your plastic parts, eliminating costly and time-consuming post-molding steps like heat staking, ultrasonic welding, or manual assembly.

Unmatched Part Reliability

By physically encapsulating inserts in plastic, we create an exceptionally strong mechanical bond that resists loosening from vibration, shock, or repeated use.

Enhanced Component Design

Our process allows for the creation of complex, consolidated parts that combine the strength and conductivity of metal with the lightweight and design freedom of plastic.

Precision & Repeatability

AI-controlled insert placement and process management ensure every insert is perfectly positioned and encapsulated, delivering superior consistency across high-volume production runs.

Human Expertise When You Need It

Our expert mold makers and plastics engineers complement AI capabilities with specialized knowledge in insert molding.

- Complex project consultation and custom tool design for secure insert holding

- Technical support for dissimilar material bonding and thermal stress management

- Quality assurance reviews for critical electronic and medical applications

- On-demand engineering support for optimizing insert design for manufacturability

Meet Our Certified Mold Makers and Automation Process Engineers

20+ Years Combined Experience

Custom Injection Molding at Wefab AI

| Feature | Specification |

|---|---|

| Process Types | Vertical and Horizontal Insert Molding, Automated Robotic Loading |

| Insert Materials | Brass, Steel, Stainless Steel, Bronze, Ceramics, Circuit Boards |

| Positional Accuracy | As tight as ±0.05 mm (±0.002"), depending on part and tool design |

| Mold Types | High-strength Steel Tooling (P20, H13, S7) with precision insert holding features |

| Strength Verification | Pull-out testing, torque testing, and visual inspection for encapsulation integrity |

| Insert Pre-treatment | Automated pre-heating available to reduce thermal stress and improve bond |

Proven Results

Samantha Lee

Senior Product Engineer, Innovate Electronics

60% reduction in cycle time on consumer electronic enclosures

The AI platform’s process window optimization was a game-changer. It delivered consistently flawless ABS parts at a speed we couldn’t achieve manually, dramatically increasing our throughput.

David Chen

Engineering Director, Precision Auto Systems

99.9% first-time-right on critical-tolerance automotive gears

The reliability is astounding. The AI’s ability to run mold flow analysis and apply predictive quality control ensured our PEEK gears met stringent performance specs from the very first shot. It saved us weeks of trial and error.

Injection Molding Capabilities

Plastic Injection Molding

High-volume production of complex and durable thermoplastic parts.

- Tolerance: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

- Lead time: Tooling from 4 weeks, parts from 5 business days after approval

Liquid Silicone Rubber Molding

Producing flexible, durable, and biocompatible parts for demanding applications.

Accuracy: ±0.2% with a lower limit of ±0.05 mm (±0.002″)

- Lead time: Tooling from 4 weeks, parts from 7 business days after approval

Overmolding

Creating multi-material parts with soft-touch grips and enhanced ergonomics.

Tolerance: ±0.3% with a lower limit of ±0.15 mm (±0.006″)

Lead time: From 6 weeks due to multi-material tooling requirements

Ready to build stronger, more reliable components?

Let our AI eliminate the complexities of insert molding and help you consolidate assembly, reduce costs, and improve part performance.

Frequently Asked Questions

How does AI improve the insert molding process?

Our AI is crucial for ensuring precise and repeatable insert placement via robotics. It optimizes melt flow to prevent insert damage or shifting during injection and uses computer vision to verify correct placement and inspect the final encapsulated part.

What is the difference between insert molding and overmolding?

Insert molding involves molding plastic around a non-plastic item (usually metal). Overmolding is the process of molding plastic over another plastic part.

How do you prevent the insert from moving during molding?

Our AI-assisted mold design incorporates precision features like pins, sleeves, or magnets that securely hold the insert in place. We also control the injection speed and pressure to create a gentle, even flow of plastic around the insert.

How does insert molding save money?

The primary cost saving comes from eliminating secondary assembly. Instead of paying for labor and equipment to press, glue, or weld inserts after molding, the process is consolidated into a single, automated step.

What design features improve an insert's strength?

To ensure the insert is permanently locked in the plastic, features like knurling (a rough, diamond-shaped pattern), grooves, undercuts, and holes can be designed into the insert to give the plastic more surface area and geometry to grip onto.