AI-Powered Manufacturing for the Electric Vehicle (EV) Industry

Building the next generation of electric vehicles requires unmatched speed, precision, and supply chain agility. Our AI-driven manufacturing platform empowers EV innovators to develop and scale their solutions, from powertrain components to the entire charging ecosystem.

“The EV market moves at an unprecedented speed. Our platform is built for agility, providing a single, streamlined interface for all your hardware needs. By integrating everything from rapid prototyping to production tooling for automotive-grade components, we help you move from concept to assembly line faster, turning innovative designs into market-leading vehicles.”

Manufacturing Solutions for the Entire EV Ecosystem

Our AI platform delivers the critical hardware needed to power the future of mobility, with the precision and scalability required for the automotive industry.

Battery Systems & Enclosures

Battery Systems & Enclosures

Build reliable, safe, and efficient battery packs. We create custom, lightweight enclosures, high-conductivity busbars, precision cooling plates, and structural mounting hardware for any pack architecture.

Key Services: Sheet Metal Works, CNC Machining, Injection Molding

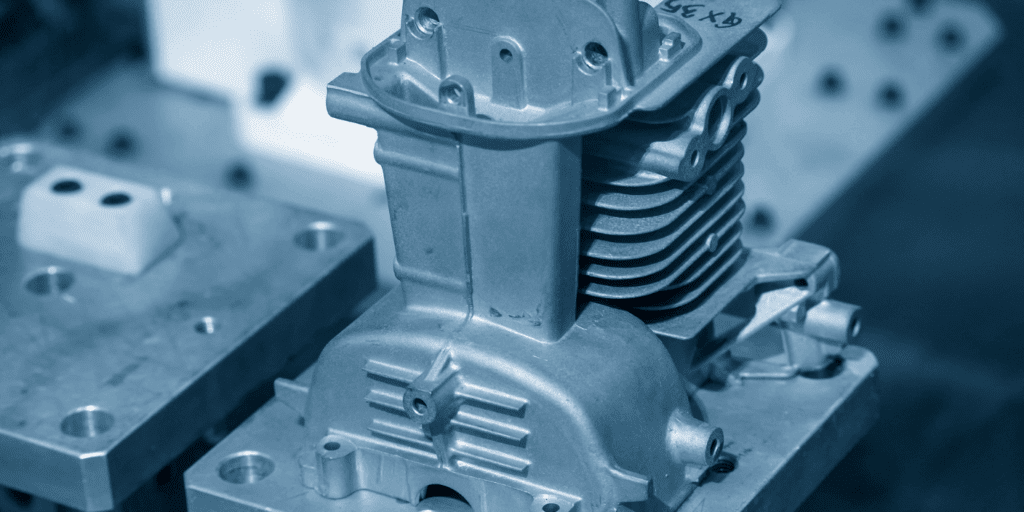

Powertrain & Drive-train Components

Powertrain & Drive-train Components

Manufacture high-performance powertrain systems with exceptional precision. We produce tight-tolerance motor housings, inverter cases, gearbox components, and custom mounts that meet the demanding requirements of electric propulsion.

Key Services: CNC Machining, DMLS (Metal 3D Printing), Tooling and Die Making

Chassis, Body & Interior

Chassis, Body & Interior

Construct every part of your vehicle, from structural components to finished interior trim. We produce custom brackets, suspension parts, lightweight body panels, and production-grade interior components.

Key Services: CNC Machining, Fabrication, Injection Molding

EV Charging Infrastructure (EVSE)

EV Charging Infrastructure (EVSE)

Accelerate the deployment of charging networks. We produce durable, weatherproof enclosures for Level 2 and DC fast chargers, as well as the internal brackets, connectors, and cosmetic components.

Key Services: Injection Molding, Sheet Metal Works, CNC Machining

Quality Assurance

Quality Assurance

Our AI captures your project needs through an intuitive interface, ensuring accuracy from the start.

Automated defect detection

Logistics Coordination

Logistics Coordination

From packaging to delivery the AI optimizes logistics for speed and cost.

Seamless coordination

Why EV Innovators Choose Wefab AI?

Accelerate Your

Time to Market

In the hyper-competitive EV race, speed is your advantage. Our AI-powered platform provides instant quotes, automated DFM feedback, and parallel production across all services, drastically cutting down development and procurement time for your most critical components.

Simplify Your Complex

Automotive Supply Chain

An electric vehicle has a complex bill of materials requiring numerous manufacturing processes. Wefab AI is your single partner for the entire BOM. Stop coordinating between machine shops, fabricators, and molders, and let our platform handle the logistics and quality for your entire vehicle system.

Seamlessly Scale from

Prototype to Production

Your EV solution needs a clear path to mass production. Our platform is designed to scale with you, from a single prototype for a test vehicle to tens of thousands of production units. With in-house tooling and die making, we provide a seamless transition to high-volume manufacturing.

Access Diverse Materials for Lightweighting & Performance

From high-strength, lightweight aluminum for chassis components to flame-retardant polymers for battery systems, we have the right material and process for your application. Our platform gives you access to a vast range of manufacturing capabilities to meet any performance or safety requirement.

Our Full Suite of Services for the EV Industry

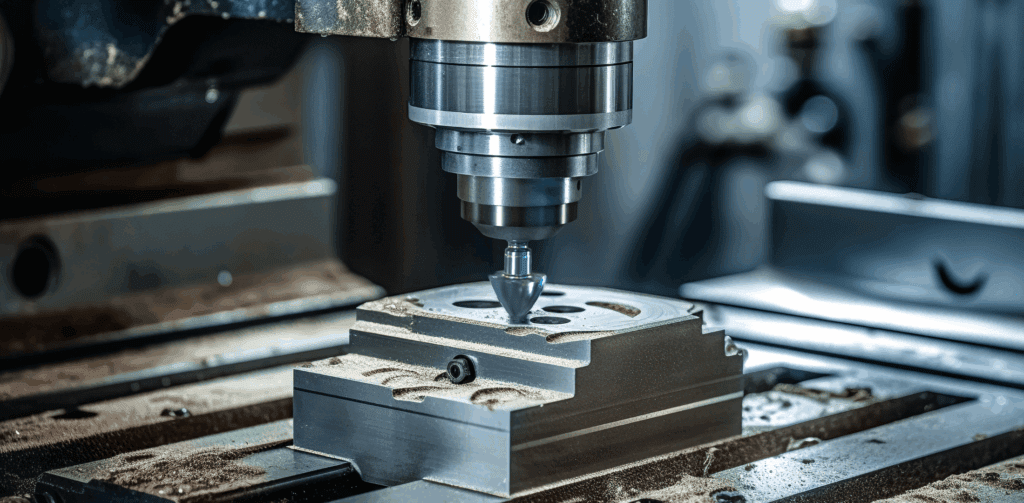

CNC Machining

High-precision milling and turning for critical robotic joints, motor mounts, shafts, and custom machine components from metal and plastic.

- Tolerance: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

- Lead time: Tooling from 4 weeks, parts from 5 business days after approval

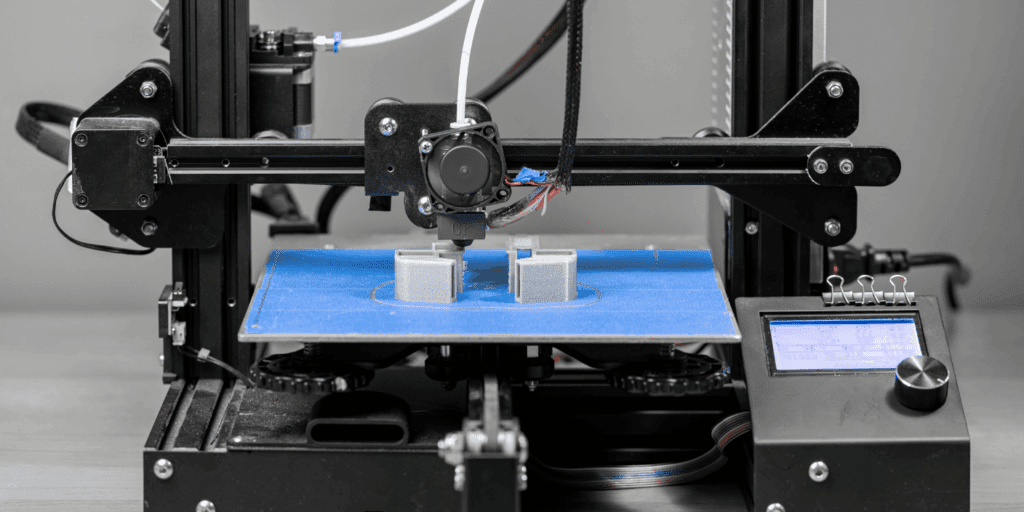

3D Printing

Rapid prototyping and production of complex geometries for custom sensor brackets, EOAT components, and durable nylon housings.

Accuracy: ±0.2% with a lower limit of ±0.05 mm (±0.002″)

- Lead time: Tooling from 4 weeks, parts from 7 business days after approval

Injection Molding

Scale your production with thousands of identical, low-cost plastic parts for robot shells, internal gears, and product casings.

Tolerance: ±0.3% with a lower limit of ±0.15 mm (±0.006″)

Lead time: From 6 weeks due to multi-material tooling requirements

Sheet Metal Works

Custom-formed brackets, panels, and enclosures for control boxes, electronics chassis, and machine guarding.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

Fabrication

Large-scale structural frames, machine bases, and support weldments for robots and industrial automation systems.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

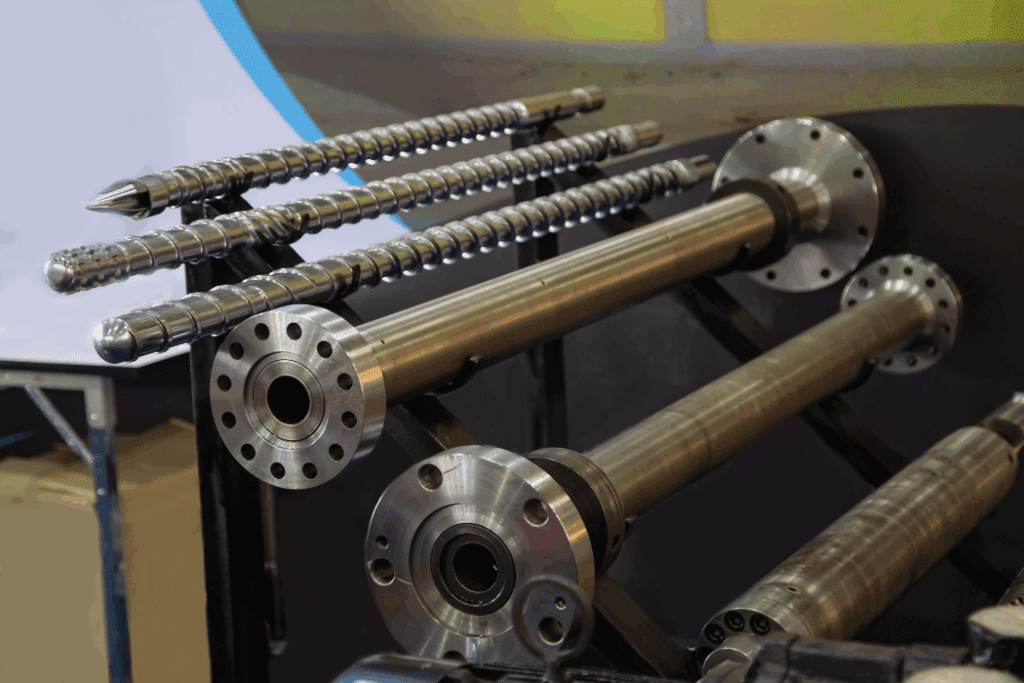

Tooling and Die Making

In-house design and creation of production-grade injection molds, custom dies, and the fixtures needed for your automated line.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

Trusted By Innovative Hardware Companies

Industrial Automation

Robotics

Trusted By EV and Automotive Innovators

Human Expertise When You Need It

Our expert engineers complement AI capabilities with deep experience in the demands of the automotive and EV sectors.

- Material selection for lightweighting, thermal management, and high-voltage applications.

- Design for Manufacturability (DFM) for battery systems, powertrains, and EVSE.

- Guidance on transitioning from prototyping to automotive-grade production standards.

- Consultation on assembly integration and multi-part system manufacturing.

20+ Years Combined Experience

Meet Our Manufacturing Engineers and EV Application Specialists

Proven Results in the EV Industry

1,000 Prototypes in 48 Hours

Robert Taylor

Engineering Manager, EV Power Systems

50% Reduction in Battery Pack Prototyping Cycle

“Wefab’s platform was a game-changer for our Gen 2 battery pack. We sourced CNC-machined cooling plates and sheet metal enclosures in just 3 weeks, enabling rapid thermal testing and cutting our validation cycle in half.”

Custom Medical Devices

Samantha Lee

Senior Product Engineer, Innovate Energy

Accelerated Market Launch for EV Charging Station

“We needed to scale our new fast charger to meet market demand. Wefab’s AI platform managed the tooling and production injection molding for our main housing, delivering the first 10,000 units flawlessly and accelerating our market launch by two months.”

Ready to Drive the Future of Mobility?

Let our AI-powered manufacturing platform provide the hardware to accelerate your innovation, from the first prototype to the full production vehicle.

Frequently Asked Questions

What materials do you offer for battery enclosures and components?

We offer a wide range of materials suitable for battery systems. For metal enclosures and cooling plates, we recommend Aluminum (5052 and 6061). For plastic components, we use high-performance, flame-retardant grades like Polycarbonate (PC) and PC/ABS.

How can you help us get our vehicle to market faster?

Our platform is built for speed. Rapid prototyping with 3D Printing and CNC Machining allows for quick design validation. Our AI-driven DFM feedback and streamlined project management across all services reduce development cycles and eliminate supply chain bottlenecks.

Can you handle the precision required for EV powertrain parts?

Yes. Our CNC Machining service is designed for high-precision applications. We can hold tolerances as tight as ±0.025 mm (±0.001″) on critical features for components like motor housings, shafts, and inverter cases.

Do you work with EV startups as well as established OEMs?

Absolutely. Our platform is designed to scale with you. We can produce a single prototype for a new startup or manage a production run of hundreds of thousands of units for a large OEM.

Can you manufacture the complete housing for our EV chargers?

Yes. We are a one-stop shop for EVSE (Electric Vehicle Supply Equipment). We use Sheet Metal Works for the main structural body and internal brackets, and Injection Molding for cosmetic covers, light pipes, and connector components.