AI-Powered Manufacturing for Consumer Hardware Industry

From a brilliant idea to a product in millions of hands, launching consumer hardware is a race against time, cost, and complexity. Our AI-driven manufacturing platform provides the speed, aesthetic quality, and scalability to bring your vision to life.

“The consumer market waits for no one. Our AI platform integrates rapid prototyping with production tooling and molding, creating a seamless, accelerated path from a single concept to mass production. We help you perfect your design and capture the market before the competition.”

Manufacturing Solutions for Every Consumer Product

Our AI platform delivers the precision, finish, and cost-effective production required to create successful consumer hardware, from smart home devices to high-end electronics.

Smart Home & IoT Devices

Smart Home & IoT Devices

Manufacture sleek, reliable enclosures for your connected devices. We produce everything from smart thermostat housings and security camera mounts to the internal components for IoT sensors.

Key Services: Injection Molding, 3D Printing, Sheet Metal Works

Wearables & Personal Electronics

Wearables & Personal Electronics

Build small, complex, and beautiful products designed for daily use. We create high-finish casings for wearables, premium metal parts for personal electronics, and flexible components like straps and seals.

Key Services:Injection Molding, CNC Machining, LSR Molding

Audio & Visual Equipment

Audio & Visual Equipment

Create products with premium aesthetics and acoustic performance. We manufacture CNC-machined aluminum housings for headphones, injection-molded speaker enclosures, and sheet metal chassis for audio receivers.

Key Services: CNC Machining, Injection Molding, Sheet Metal Works

Appliances & Kitchenware

Appliances & Kitchenware

Develop durable and user-friendly home goods. We produce robust housings for kitchen appliances, precision mechanical components, and the production tooling needed to manufacture at scale.

Key Services: Tooling and Die Making, Injection Molding, CNC Machining

Quality Assurance

Quality Assurance

Our AI captures your project needs through an intuitive interface, ensuring accuracy from the start.

Automated defect detection

Logistics Coordination

Logistics Coordination

From packaging to delivery the AI optimizes logistics for speed and cost.

Seamless coordination

Why Consumer Hardware Companies Choose Wefab AI?

Accelerate Your

Product Launch

In the fast-moving consumer market, speed is everything. Our platform offers instant DFM feedback and rapid tooling options that slash weeks from your development timeline, helping you hit critical market windows.

Achieve a Premium

Fit and Finish

Consumer products are judged on quality. Our expertise in scientific molding, CNC finishing, and tooling design ensures your product has the flawless, Class-A surface finish and perfect assembly your customers expect.

Seamlessly Scale to

Mass Production

We are your partner from concept to millions of units. Validate your design with prototypes, launch your product with bridge tooling, and ramp to mass production with high-cavitation molds, all within a single, integrated platform.

Simplify Your Global Supply Chain

Stop managing dozens of component suppliers. Our platform acts as your single point of contact for every part in your BOM—molded plastics, machined metal, sheet metal, and more—simplifying logistics and ensuring quality.

Our Full Suite of Services for Consumer Hardware

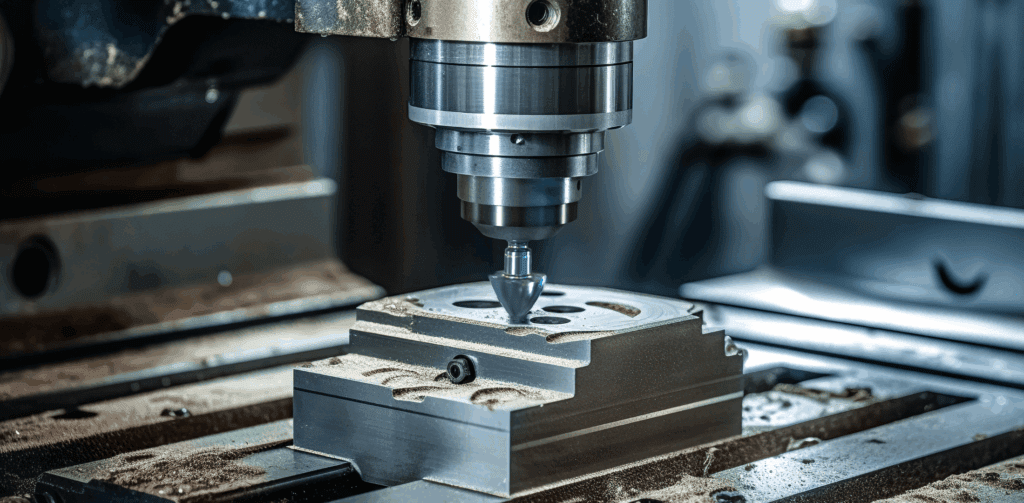

CNC Machining

High-precision milling and turning for critical robotic joints, motor mounts, shafts, and custom machine components from metal and plastic.

- Tolerance: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

- Lead time: Tooling from 4 weeks, parts from 5 business days after approval

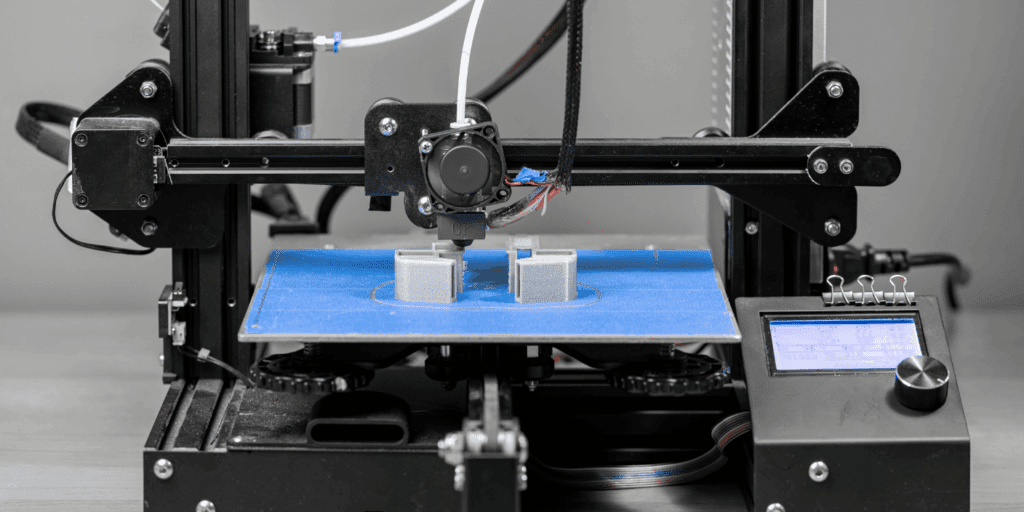

3D Printing

Rapid prototyping and production of complex geometries for custom sensor brackets, EOAT components, and durable nylon housings.

Accuracy: ±0.2% with a lower limit of ±0.05 mm (±0.002″)

- Lead time: Tooling from 4 weeks, parts from 7 business days after approval

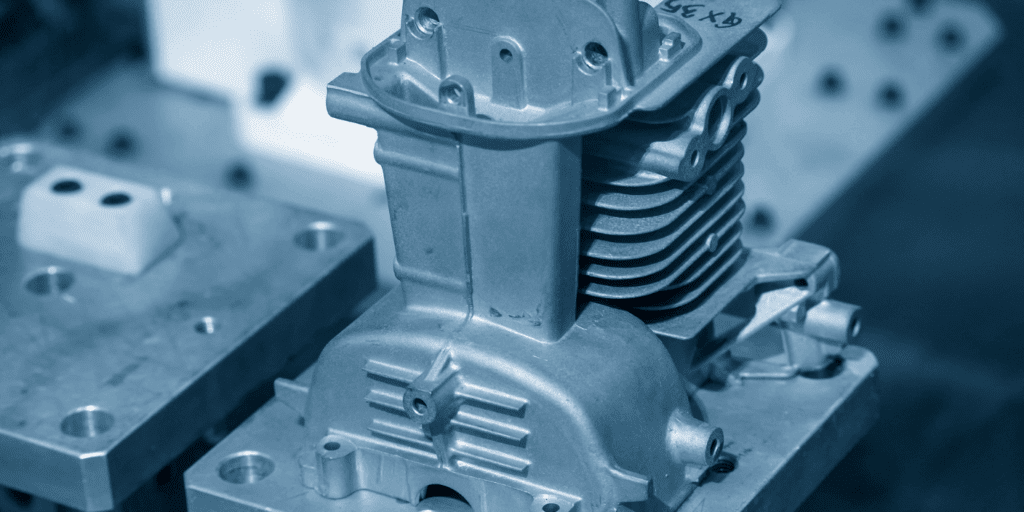

Injection Molding

Scale your production with thousands of identical, low-cost plastic parts for robot shells, internal gears, and product casings.

Tolerance: ±0.3% with a lower limit of ±0.15 mm (±0.006″)

Lead time: From 6 weeks due to multi-material tooling requirements

Sheet Metal Works

Custom-formed brackets, panels, and enclosures for control boxes, electronics chassis, and machine guarding.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

Fabrication

Large-scale structural frames, machine bases, and support weldments for robots and industrial automation systems.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

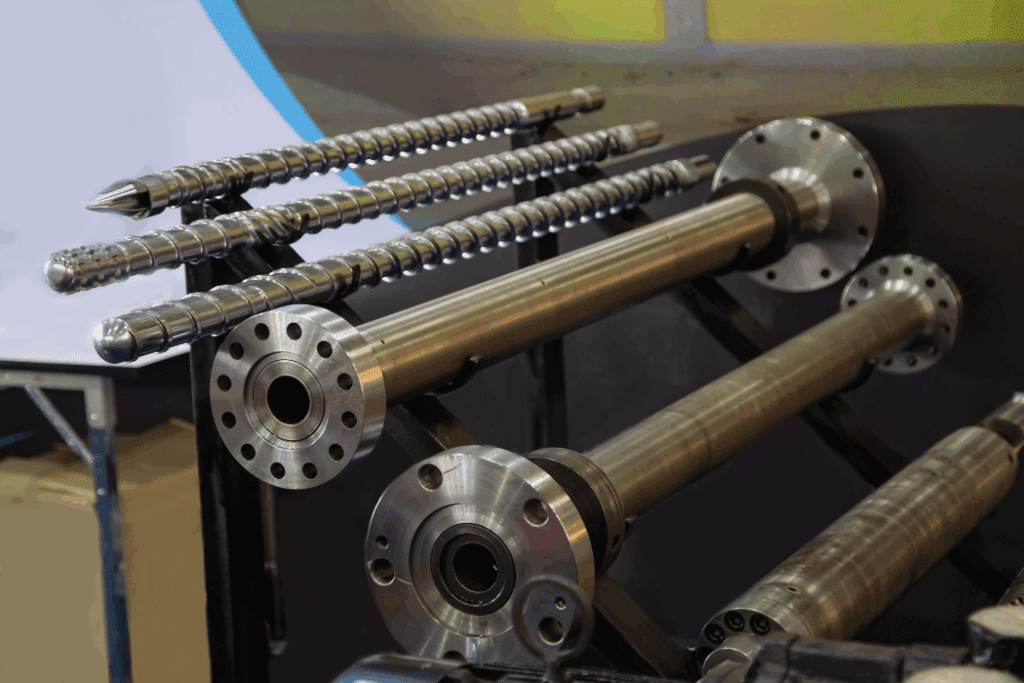

Tooling and Die Making

In-house design and creation of production-grade injection molds, custom dies, and the fixtures needed for your automated line.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

Trusted By Consumer Hardware Innovators

Trusted By Innovative Hardware Companies

EV and Automotive

Industrial Automation

Climate Tech

Consumer Electronics and Appliances

Robotics

Human Expertise When You Need It

Our expert engineers complement AI capabilities with deep experience in bringing consumer hardware to market.

- Design for Manufacturability (DFM) reviews focused on aesthetic quality and high-volume molding.

- Material selection to achieve the perfect look, feel, and durability for your product.

- Guidance on transitioning from prototyping to a cost-effective mass production strategy.

- Consultation on finishing, texturing, and color matching to perfect your brand's identity.

20+ Years Combined Experience

Meet Our Manufacturing Engineers and Consumer Product Specialists

Proven Results in the Consumer Hardware

1,000 Prototypes in 48 Hours

Samantha Lee

Senior Product Engineer, Innovate Home

5-Week Launch for Smart Home Device

“Wefab’s AI platform was the key to our successful launch. They managed the rapid tooling for our injection molded thermostat enclosures, delivering the first 5,000 units in just five weeks and allowing us to hit the holiday shopping season.”

Custom Medical Devices

David Chen

Engineering Director, Precision Audio

Flawless Assembly for High-End Audio Player

“For our flagship music player, the premium feel was non-negotiable. Wefab delivered the CNC-machined anodized aluminum body and the injection molded internal chassis. Their AI-driven DFM feedback was critical to achieving a perfect, gap-free assembly.”

Ready to Bring Your Product to Market?

Let our AI-powered manufacturing platform handle the complexities of production, so you can focus on creating the next great consumer product.

Frequently Asked Questions

How do you achieve a Class-A surface finish for consumer products?

Our AI platform manages the entire injection molding process for cosmetic perfection. We use AI-assisted mold design to predict and eliminate flow marks, high-polish SPI-A1 tooling, and real-time process control (scientific molding) to ensure a flawless, consistent finish on every part.

What are your typical turnaround times for consumer hardware prototypes?

Speed is critical for product launches. Our AI-managed platform delivers 3D printed prototypes for aesthetic and functional testing in as little as 1-3 business days and high-fidelity CNC machined prototypes in 3-5 business days, allowing for rapid design iteration.

How does Wefab support the transition from prototype to mass production?

Our AI platform provides a seamless scaling path. We start with rapid prototyping (3D Printing/CNC). For pilot runs, we offer rapid tooling for injection molding (5k-10k units). For mass production, our in-house Tooling and Die Making service creates high-cavitation steel molds capable of millions of cycles.

What materials and finishes do you offer for premium metal parts?

We CNC machine a variety of metals ideal for consumer electronics, including Aluminum 6061 and Stainless Steel. Our AI-optimized toolpaths ensure high precision. We also offer a range of finishes like bead blasting, polishing, and anodizing in multiple colors to achieve your desired aesthetic.

What file formats do you accept, and can you handle an assembly with multiple parts?

We accept STEP, STP, IGES, IGS, X_T, and other standard 3D formats. Our AI platform is designed to handle complex Bills of Materials (BOMs). You can upload your entire assembly, and the system will instantly analyze all components for manufacturability across our services (molding, CNC, sheet metal, etc.), simplifying your supply chain.