AI-Powered CNC Routing Services for Precision Parts

Our AI manages every step of the CNC routing process, delivering high-quality components faster and more efficiently than ever.

“Our AI-powered platform takes full control of your CNC routing projects, acting as your dedicated Single Point of Contact. From optimizing cut paths to ensuring flawless edge finishes, our AI works 24/7 to deliver precision components on time and within budget.”

End-to-End Production Management

Requirement Capturing

Our AI captures your project specifications through an intuitive interface, ensuring material selection, nesting requirements, edge quality, and custom engraving needs are understood from the start.

Automatic feature recognition, cut strategy, and 3D contouring optimization

Router & Bit Selection

Our AI selects the optimal routing equipment—3-axis or 5-axis CNC routers—and specialized bits for cutting, engraving, or edge profiling, based on material type, sheet size, part complexity, and secondary operation needs.

Intelligent collet, bit, and spindle selection for multi-material processing and precision engraving

Design for Routability

The AI optimizes your design for routing, analyzing features for tool clearance, material hold-down, vibration control, and compatibility with multi-material stacks or intricate 3D profiling.

Real-time DFM with material waste minimization, nested layout planning, and engraving path refinement

Project Monitoring

Track routing operations in real-time with AI-powered updates on spindle speed, feed rates, edge quality, and custom fixturing performance for complex 3D contours or multi-sided parts.

Live monitoring of dust extraction, material stability, and engraving depth consistency

Follow-ups & Reporting

Stay informed with automated follow-ups and detailed reports on material yield, dimensional inspection, edge finish, engraving accuracy, and secondary operation integration like edge banding.

Comprehensive part verification, yield documentation, and multi-process reporting

Quality Assurance

AI coordinates dimensional inspection, edge finish verification, and engraving quality checks, ensuring parts meet specifications with minimal defects across flat panels, contoured surfaces, and multi-material assemblies.

Automated edge quality assessment, dimensional verification, and engraving precision validation

Risk Analysis

The AI identifies routing risks like material tear-out, chip load issues, vacuum hold-down failures, or misalignment during 3D contouring and implements compensating strategies proactively.

Predictive feed rate adjustments, climb/conventional cutting, and custom fixture optimization

Logistics Coordination

From edge banding, surface finishing, and assembly operations to packaging and delivery, the AI optimizes the post-routing workflow for speed, cost, and integration with downstream processes.

Seamless coordination of secondary operations like edge banding and custom kitting

Why Choose Our

AI Platform

24/7 Production Capability

Our AI never sleeps, managing your routing projects across multiple tables and shifts.

Unmatched Detail

Optimized cut paths and nesting layouts mean minimal material waste and faster cycle times.

Exceptional Precision

AI compensates for material variations and tool runout, delivering consistent edge quality.

Cost-Effective Manufacturing

Smart nesting optimization, reduced setup times, and optimized material yield offer competitive pricing.

Proactive Solutions

Router bit wear, spoilboard issues, and material inconsistencies are detected and addressed before they affect part quality.

Human Expertise When You Need It

Our expert machinists and engineers complement AI capabilities with specialized knowledge and hands-on experience.

- Complex project consultation and custom fixture design

- Technical support for exotic materials and tight tolerance requirements

- Quality assurance reviews for critical applications

- On-demand engineering support and design optimization

Meet Our Master Router Programmers and CNC Specialists

20+ Years Combined Experience

Proven Results

Jennifer Morris

Production Director, ChargeTech Solutions

50% faster production on composite material components

The AI-driven routing process transformed our panel production. The intelligent nesting optimization and feed rate control delivered perfectly cut openings with clean edges, accelerating our charging station deployment timeline.

David Wong

Design Manager, TechRetail Innovations

95% material yield on premium hardwood displays

The precision and efficiency we’ve achieved with Wefab.ai’s CNC routing platform have been crucial for our retail displays. The AI’s ability to optimize material usage while maintaining premium edge finishes has significantly improved our sustainability metrics. David Wong, Design Manager, TechRetail Innovations

CNC Machining Capabilities

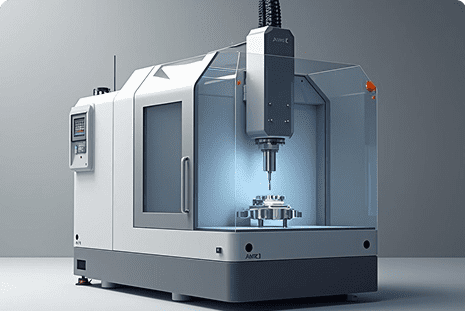

CNC Milling

High-precision machining for complex parts.

- Dimensional accuracy of ± 0.1% with a lower limit of ± 0.05 mm (± 0.002″)

- Lead times from 3 business days

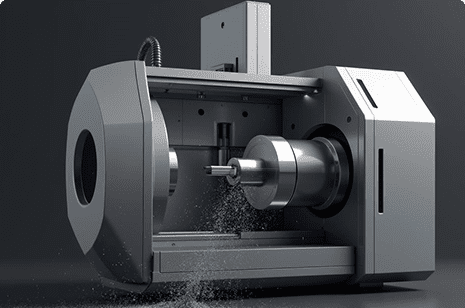

CNC Turning

Precision machining for cylindrical parts.

- Dimensional accuracy of ± 0.2% with a lower limit of ± 0.02 mm (± 0.0008″)

- Lead times from 2 business days

Wire EDM Machining

Intricate shapes and extreme hardness applications.

- Dimensional accuracy of ± 0.1% with a lower limit of ± 0.005 mm (± 0.0002″)

- Lead times from 5 business days

Ready to experience the future of precision CNC routing?

Let our AI work for you and transform your manufacturing process with intelligent routing strategies and unmatched edge quality.

Frequently Asked Questions

How does AI improve the CNC routing process?

Our AI optimizes cut paths, nesting layouts, and feed rates, reducing material waste and improving edge quality. It continuously learns from past operations to minimize tear-out and predict optimal router settings.

What materials can you route?

We process wood, plywood, MDF, acrylics, composites, aluminum, foam, and various plastics. Our AI automatically adjusts spindle speeds, feed rates, and bit selection for each material type.

What are your typical turnaround times for routed parts?

Simple flat components can be completed in 2-3 days, while complex 3D parts requiring 5-axis routing may take 4-7 business days. Production runs are scheduled with JIT delivery options.

How do you ensure part accuracy in CNC routing?

Our AI employs vacuum hold-down optimization, tool path compensation, and spindle speed control. Parts undergo dimensional inspection with capability for holding tolerances to ±0.005″ on critical features.

What file formats do you accept for CNC routing projects?

We accept DXF, AI, PDF, STEP, and other standard CAD formats. Our AI can also optimize vector files for efficient nested cutting to maximize material yield.