AI-Powered CNC Milling Services for High-Precision Parts

Our AI manages every step of the CNC milling process, delivering high-quality machined components with greater speed and efficiency than ever before.

“Our AI-powered platform takes full control of your CNC milling projects, acting as your dedicated Single Point of Contact. From optimizing toolpaths to ensuring flawless surface finishes, our AI works 24/7 to deliver precision-machined metal and plastic components on time and within budget.”

End-to-End Production Management

Requirement Capturing

Our AI captures your project specifications through an intuitive interface, ensuring material selection, mechanical requirements, and critical tolerances are understood from the start

Interactive project setup with instant manufacturability feedback

Machine & Material Selection

Our AI selects the optimal CNC machine (3-axis, 4-axis, or 5-axis) and tooling based on part geometry, material, production volume, and required surface finish.

Intelligent stock selection and spindle speed optimization

Design for Manufacturability (DFM)

The AI optimizes your design for CNC milling, providing instant feedback on feature feasibility, tool accessibility, and potential work-holding challenges.

Real-time DFM with fixture analysis and cycle time estimation

Project Monitoring

Track milling operations in real-time with AI-powered updates on machining progress, tool wear, and dimensional accuracy.

Live monitoring of machine performance and coolant temperature

Follow-ups & Reporting

Stay informed with automated follow-ups and detailed reports on material certification, dimensional inspection, and surface roughness.

Comprehensive build completion documentation

Quality Assurance

AI coordinates CMM inspection and surface finish verification, ensuring parts meet specifications with minimal deburring or secondary operations.

Automated geometric dimensioning and tolerancing (GD&T) validation

Risk Analysis

The AI identifies machining risks like tool deflection, chatter, or thermal expansion and implements compensating strategies proactively.

Predictive toolpath adjustments and feed rate optimization

Logistics Coordination

From material procurement and machining to finishing and delivery, the AI optimizes the entire workflow for speed and cost.

Seamless coordination of secondary operations like anodizing or plating

Why Choose Our

AI Platform

24/7 Production Capability

Our AI never sleeps, managing your CNC projects across multiple machines and materials.

Unmatched Detail

Optimized toolpaths and intelligent work-holding mean faster cycle times and reduced material waste.

Exceptional Precision

AI compensates for tool wear and thermal variations, delivering consistent dimensional accuracy.

Cost-Effective Manufacturing

Smart stock utilization, optimized cycle times, and reduced manual oversight offer competitive pricing.

Proactive Solutions

Material inconsistencies, tool degradation, and machining anomalies are detected and addressed before they affect part quality.

Human Expertise When You Need It

Our expert machinists and engineers complement AI capabilities with specialized knowledge and hands-on experience.

- Complex project consultation and custom fixture design

- Technical support for exotic materials and tight tolerance requirements

- Quality assurance reviews for critical applications

- On-demand engineering support and design optimization

Certified CNC Machinists and Manufacturing Engineers

20+ Years Combined Experience

CNC Machining Capabilities

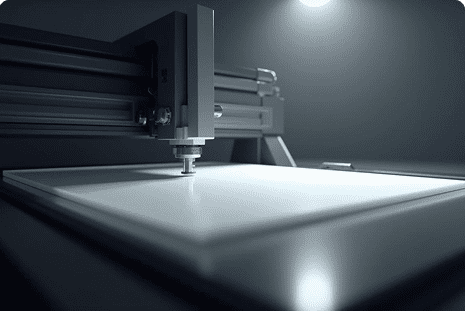

CNC Routing

Fast and efficient cutting of sheet materials.

- Dimensional accuracy of ± 0.5% with a lower limit of ± 0.5 mm (± 0.020″)

- Lead times from 2 business days

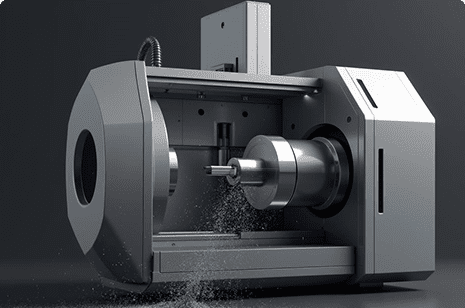

CNC Turning

Precision machining for cylindrical parts.

- Dimensional accuracy of ± 0.2% with a lower limit of ± 0.02 mm (± 0.0008″)

- Lead times from 2 business days

Wire EDM Machining

Intricate shapes and extreme hardness applications.

- Dimensional accuracy of ± 0.1% with a lower limit of ± 0.005 mm (± 0.0002″)

- Lead times from 5 business days

Ready to experience the future of CNC milling?

Let our AI work for you and transform your manufacturing process with intelligent machining strategies and unmatched part quality.

Frequently Asked Questions

How does AI improve the CNC milling process?

Our AI optimizes toolpaths, feed rates, and cutting strategies, reducing cycle time and enhancing surface finish. It continuously learns from past jobs to minimize tool chatter, predict tool wear, and select the optimal parameters for each material.

What materials can you mill?

We process a wide range of metals (Aluminum, Steel, Stainless Steel, Titanium, Brass) and plastics (ABS, Polycarbonate, PEEK, Delrin). Our AI automatically adjusts spindle speed, feed rate, and tool selection for each material’s unique properties.

What are your typical turnaround times for CNC milled parts?

Simple components can be completed in 3-5 days, while complex parts or large production runs may take 6-10 business days. The AI optimizes machine schedules to maintain consistency while maximizing throughput.

How do you ensure part accuracy in CNC milling?

Our AI employs in-process probing, real-time tool compensation, and optimized cutting strategies. Each component undergoes CMM inspection, with the capability for holding tolerances to ±0.001″ (0.025 mm) on critical features, depending on geometry and material.

What file formats do you accept for CNC milling projects?

We accept STEP, STP, IGES, IGS, X_T, and other standard 3D model formats. Our AI can also analyze designs for manufacturability and provide feedback to ensure successful production.