AI-Powered Manufacturing for the Climate Tech Revolution

Building the hardware to solve climate change requires speed, precision, and a resilient supply chain. Our AI-driven manufacturing platform empowers Climate Tech pioneers to develop and scale their solutions, from renewable energy components to carbon capture systems.

“The urgency of the climate crisis demands rapid innovation. Our platform is built for speed, providing a single, streamlined interface for all your hardware needs. By integrating everything from rapid prototyping to production tooling, we help you move from concept to field deployment faster, turning groundbreaking ideas into global impact.”

Manufacturing Solutions for Every Climate Tech Sector

Our AI platform delivers the critical hardware needed to power a sustainable future, with the precision and scalability to meet the moment.

Renewable Energy & Grid Modernization

Renewable Energy & Grid Modernization

Manufacture the core components for solar, wind, and other renewable energy systems. We produce high-strength mounting hardware, durable enclosures for inverters and control systems, and precision components for turbines.

Key Services: Sheet Metal Works, CNC Machining, Fabrication

Energy Storage & Batteries

Energy Storage & Batteries

Build reliable and efficient energy storage solutions. We create custom battery enclosures, high-conductivity busbars, thermal management components, and large-scale racking systems for battery farms.

Key Services: Injection Molding, CNC Machining, Sheet Metal Works

Carbon Capture, Utilization & Storage (CCUS)

Carbon Capture, Utilization & Storage (CCUS)

Develop and deploy advanced carbon removal technologies. We manufacture complex components for direct air capture (DAC) systems, including custom manifolds, sensor housings, and reactor components from chemical-resistant materials.

Key Services: CNC Machining, DMLS (Metal 3D Printing), Fabrication

Electric Mobility & EV Infrastructure

Electric Mobility & EV Infrastructure

Accelerate the transition to electric transportation. We produce durable enclosures for EV charging stations, lightweight vehicle components, battery pack components, and custom parts for the entire EV ecosystem.

Key Services: Fabrication, Sheet Metal Works, CNC MachiningOur Full Suite of Services for Automation

Quality Assurance

Quality Assurance

Our AI captures your project needs through an intuitive interface, ensuring accuracy from the start.

Automated defect detection

Logistics Coordination

Logistics Coordination

From packaging to delivery the AI optimizes logistics for speed and cost.

Seamless coordination

Why Climate Tech Innovators Choose Wefab AI?

Accelerate Your

Time to Market

In the race against climate change, speed is critical. Our AI-powered platform provides instant quotes, automated DFM feedback, and streamlined project management across all services. This integration drastically reduces development cycles, helping you move from concept to field-ready hardware faster than traditional manufacturing.

Simplify Your Complex

Supply Chain

Climate tech hardware is complex, often requiring CNC machining, sheet metal, fabrication, and injection molding for a single system. Wefab AI is your single partner for the entire bill of materials. Stop managing multiple suppliers and let our platform handle the logistics, ensuring all your components are delivered on time and to spec.

Seamlessly Scale from

Prototype to Production

Your climate solution needs a clear path to global impact. Our platform is designed to scale with you, from a single prototype to tens of thousands of production units. With in-house tooling and die making, we provide a seamless transition to high-volume manufacturing without changing suppliers.

Access Diverse Materials &

Processes for Harsh Environments

From robust, corrosion-resistant metals for outdoor enclosures to high-performance polymers for lightweight components, we have the right material and process for your application. Our platform gives you access to a vast range of manufacturing capabilities to meet any performance or environmental challenge.

Our Full Suite of Services for Climate Tech

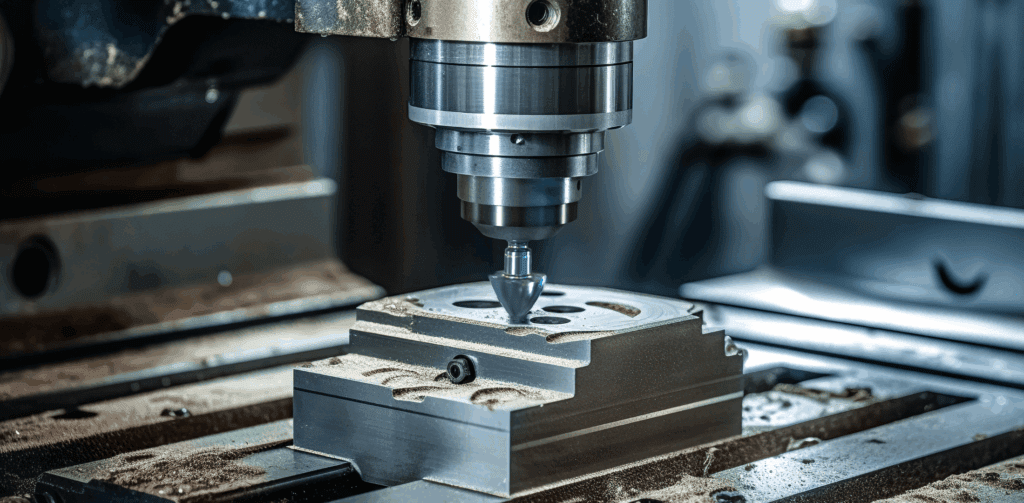

CNC Machining

High-precision milling and turning for critical robotic joints, motor mounts, shafts, and custom machine components from metal and plastic.

- Tolerance: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

- Lead time: Tooling from 4 weeks, parts from 5 business days after approval

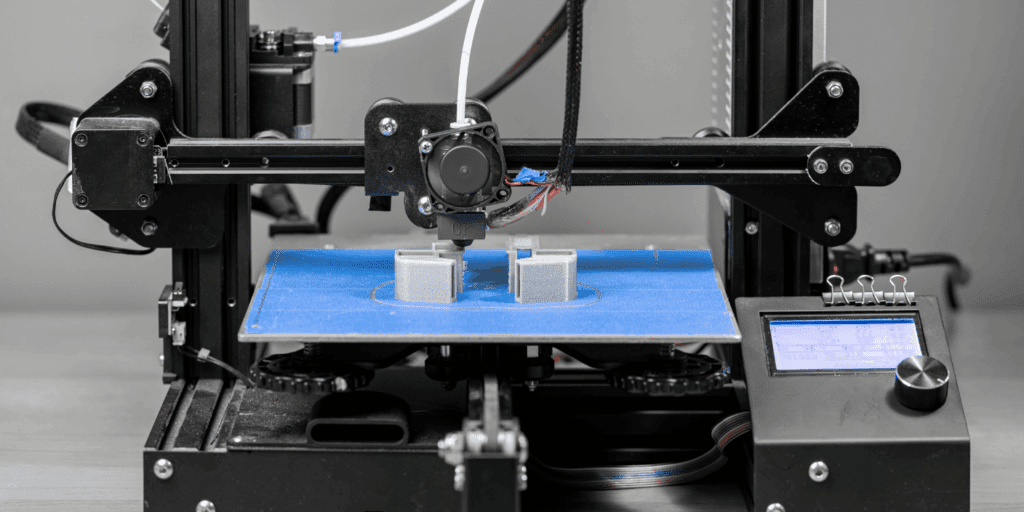

3D Printing

Rapid prototyping and production of complex geometries for custom sensor brackets, EOAT components, and durable nylon housings.

Accuracy: ±0.2% with a lower limit of ±0.05 mm (±0.002″)

- Lead time: Tooling from 4 weeks, parts from 7 business days after approval

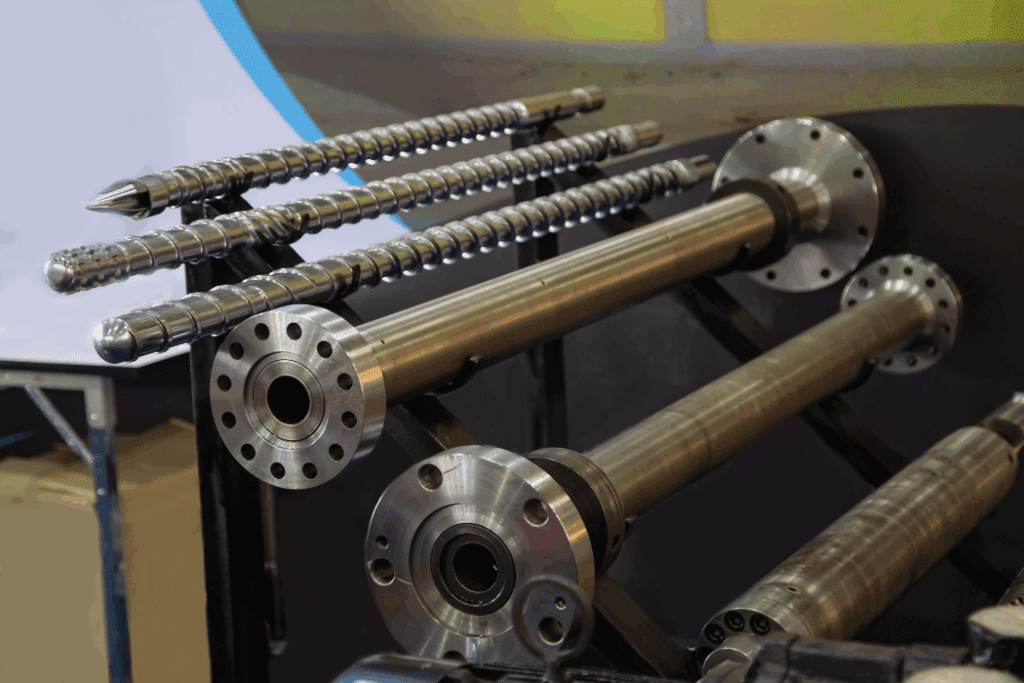

Injection Molding

Scale your production with thousands of identical, low-cost plastic parts for robot shells, internal gears, and product casings.

Tolerance: ±0.3% with a lower limit of ±0.15 mm (±0.006″)

Lead time: From 6 weeks due to multi-material tooling requirements

Sheet Metal Works

Custom-formed brackets, panels, and enclosures for control boxes, electronics chassis, and machine guarding.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

Fabrication

Large-scale structural frames, machine bases, and support weldments for robots and industrial automation systems.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

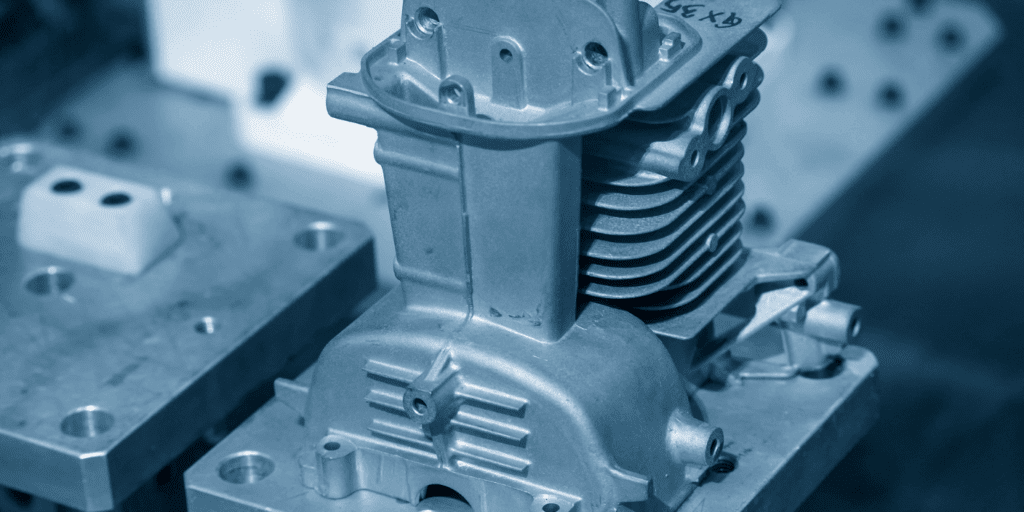

Tooling and Die Making

In-house design and creation of production-grade injection molds, custom dies, and the fixtures needed for your automated line.

Precision: ±0.2% with a lower limit of ±0.1 mm (±0.004″)

Lead time: From 5 weeks to account for insert validation and process setup

Trusted By Innovative Hardware Companies

Industrial Automation

Robotics

Trusted By Innovative Climate Tech Companies

Human Expertise When You Need It

Our expert engineers complement AI capabilities with deep experience in manufacturing for the energy and environmental sectors.

- Material selection for harsh outdoor environments, UV resistance, and chemical compatibility.

- Design for Manufacturability (DFM) reviews to improve efficiency and performance.

- Guidance on scaling from functional prototypes to mass deployment and grid-scale projects.

- Consultation on achieving certifications and meeting industrial-grade standards.

20+ Years Combined Experience

Meet Our Manufacturing Engineers and Climate Tech Application Specialists

Proven Results in Climate Tech

1,000 Prototypes in 48 Hours

Samantha Lee

Senior Product Engineer, Innovate Solar

4-Month Acceleration for Smart Solar Tracking System

“Wefab’s AI platform was instrumental in launching our solar tracker. We sourced CNC-machined actuators, sheet metal enclosures, and injection molded sensor housings through one portal. The speed and reliability of the platform accelerated our field deployment by four months.”

Custom Medical Devices

David Chen

Engineering Director, Carbon Solutions

Successful Pilot of a Modular Carbon Capture Unit

“For our direct air capture pilot, we needed a partner who could handle a complex, multi-process BOM. Wefab delivered the fabricated frame, custom CNC-machined manifolds, and 3D printed components for airflow testing. Their all-in-one platform was critical to our success.”

Ready to Build a Sustainable Future?

Let our AI-powered manufacturing platform provide the hardware foundation for your climate solution, helping you innovate and scale faster.

Frequently Asked Questions

What materials do you offer for outdoor or harsh environments?

We offer a wide range of durable materials. For metals, we recommend anodized aluminum and stainless steel (304 & 316). For plastics, we offer UV-resistant grades like ASA and robust engineering plastics like Polycarbonate and Nylon.

How can you help us get our hardware to market faster?

Our platform is built for speed. Rapid prototyping with 3D Printing and CNC Machining allows for quick design validation. Our AI-driven DFM feedback and streamlined project management across all services reduce development cycles and eliminate supply chain bottlenecks.

Can you handle the large components needed for energy systems?

Yes. Our Fabrication service specializes in large, welded structures like frames and mounting racks. We also have large-format CNC machines for bigger components.

Do you work with startups and researchers in the climate tech space?

Absolutely. Our platform is designed to scale with you. We can produce a single prototype for a university research project or manage a production run of thousands of units for a growing company.

Can you produce parts that are chemically resistant for carbon capture?

Yes. We machine a variety of chemical-resistant materials, including Stainless Steel 316, PEEK, and PTFE, which are well-suited for the components used in carbon capture and sequestration systems.