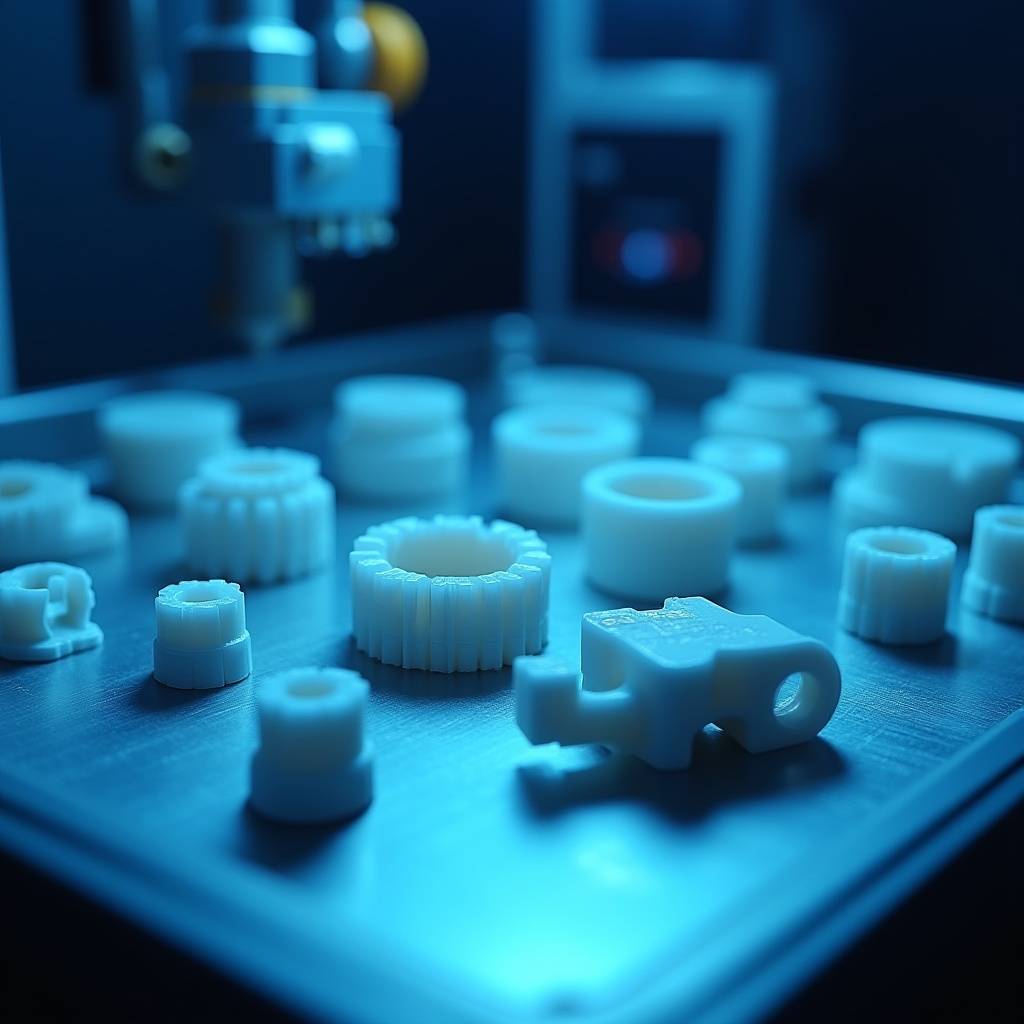

AI-Powered Carbon DLS 3D Printing Services

Our AI manages every step of the Carbon DLS process, delivering high-quality parts faster and more efficiently than ever.

AI-Powered Carbon DLS for Isotropic Accuracy and Accelerated Builds

Our AI manages every step of the Carbon DLS process, delivering high-quality parts faster and more efficiently than ever.

“Our AI-powered platform takes full control of your Carbon DLS projects, acting as your dedicated Single Point of Contact. From optimizing build parameters to ensuring flawless surface finishes, our AI works 24/7 to deliver precision components on time and within budget.”

End-to-End Production Management

Requirement Capturing

Our AI captures your project specifications through an intuitive interface, ensuring material selection, tolerances, and surface finish requirements are understood from the start.

Automatic feature recognition and print strategy selection

Material & Parameter Selection

Our AI selects the optimal Carbon DLS materials—EPU, EPX, RPU, FPU, or SIL—based on part requirements, mechanical properties, and performance needs. Intelligent print parameter optimization for maximum part performance

Intelligent print parameter optimization for maximum part performance

Design for Printability

The AI optimizes your design for Carbon DLS, analyzing features for printability, support requirements, and potential manufacturing challenges.

Real-time DFP with wall thickness analysis and support planning

Project Monitoring

Track DLS operations in real-time with AI-powered updates on build progress, resin consumption, and dimensional accuracy.

Live monitoring of printing parameters and curing conditions

Follow-ups & Reporting

Stay informed with automated follow-ups and detailed reports on material certification, dimensional inspection, and surface finish verification.

Comprehensive first article inspection documentation

Quality Assurance

AI coordinates CMM inspection and surface finish verification, ensuring parts meet specifications with minimal deviation.

Automated dimensional inspection and surface quality validation

Risk Analysis

The AI identifies printing risks like feature distortion, support failures, or curing issues and implements compensating strategies proactively.

Predictive build adjustments and layer optimization

Post-Processing Coordination

From support removal and cleaning to curing and finishing operations, the AI optimizes the post-printing workflow for speed and cost.

Seamless coordination of secondary operations

Why Choose Our

AI Platform

24/7 Production Capability

Our AI never sleeps, managing your Carbon DLS projects across multiple machines and shifts.

Unmatched Efficiency

Optimized build parameters and layering strategies mean faster production times and reduced material waste.

Exceptional Precision

AI compensates for resin behavior and curing variations, delivering tight tolerances consistently.

Cost-Effective Manufacturing

Smart material selection, optimized part orientation, and reduced post-processing times offer competitive pricing.

Proactive Solutions

Layer adhesion, support integrity, and dimensional accuracy are monitored and addressed before they affect part quality.

Human Expertise When You Need It

Our experts complement AI capabilities with specialized knowledge and hands-on experience

- Complex project consultation and custom solutions design

- Technical support for specialized materials and finishing requirements

- Quality assurance reviews for critical applications

- On-demand engineering support and design optimization

Meet Our Carbon DLS Specialists and Additive Manufacturing Experts

20+ Years Combined Experience

Complex project consultation and custom solutions design

Technical support for specialized materials and finishing requirements

Quality assurance reviews for critical applications

On-deman engineering support and design optimization

Meet Our Carbon DLS Specialists and Additive Manufacturing Experts

20+ Years Combined Experience

Proven Results

James Wilson

Production Manager, PrecisionTech Industries

45% faster production times on complex elastomeric components

The AI-driven Carbon DLS process transformed our medical device component production. The intelligent print parameter optimization and adaptive curing profiles delivered perfectly printed parts with excellent mechanical properties, accelerating our manufacturing timeline. Jessica Morales, Production Manager, MediTech Innovations

Dr. Emma Rodriguez

R&D Director, ImplantSolutions Medical

99.2% first-time-right rate on precision functional prototypes

The precision and consistency we’ve achieved with Wefab.ai’s Carbon DLS platform have been crucial for our rapid prototyping needs. The AI’s ability to maintain tight tolerances while optimizing material performance has dramatically improved our product development cycles. Michael Zhang, Product Development Director, AeroFlex Systems

Our 3d Printing Capabilities

Plastic 3D Printing Service

Quick and cost-effective 3D printing solutions

- Precision level: ±0.5% with a minimum of 0.6 mm

- Turnaround: Starting from 2 business days

FDM 3D Printing

Efficient and budget-friendly prototyping

- Accuracy: ±0.5% with a minimum of 0.5 mm

- Delivery: As fast as 1 business day

Multi Jet Fusion

Robust prototyping and small-batch production

- Precision: ±0.3% with a minimum of 0.3 mm

- Lead time: From 2 business days

SLS 3D Printing

Durable and versatile printing options

- Tolerance: ±0.3% with a minimum of 0.4 mm

- Processing time: Starting from 3 business days

Stereolithography - SLA 3D Printing

High-detail visual prototyping

- Accuracy: ±0.3% with a minimum of 0.3 mm

- Turnaround: From 2 business days

PolyJet 3D Printing

Precise and multi-material printing

- Dimensional accuracy: ±0.2% with a minimum of 0.2 mm

- Delivery: Starting from 2 business days

Carbon DLS

Fast and flexible production-grade parts

- Precision: ±0.4% with a minimum of 0.5 mm

- Lead time: From 3 business days

Metal 3D Printing Service

High-strength metal part fabrication

- Tolerance: ±0.3% with a minimum of 0.4 mm

- Turnaround: Starting from 4 business days

Direct Metal Laser Sintering

Advanced metal prototyping and production

- Accuracy: ±0.3% with a minimum of 0.3 mm

- Delivery: From 5 business days

Ready to experience the future of precision digital manufacturing?

Let our AI work for you and transform your production process with intelligent Carbon DLS strategies and unmatched part quality.

Frequently Asked Questions

How does AI improve the Carbon DLS process?

Our AI optimizes build parameters, part orientation, and support strategies, reducing production times and enhancing surface quality. It continuously learns from past operations to minimize material usage and predict optimal printing parameters for each geometry.

What materials can you print with Carbon DLS?

At Wefab.ai we use the complete range of Carbon DLS materials including EPU (elastomeric polyurethane), RPU (rigid polyurethane), EPX (epoxy), FPU (flexible polyurethane), and SIL (silicone) resins. Our AI automatically adjusts printing and curing parameters for each material’s unique properties.

What are your typical turnaround times for Carbon DLS parts?

Simple components can be completed in 1-3 days, while complex parts requiring extensive post-processing may take 3-5 business days.

How do you ensure part accuracy in Carbon DLS printing?

Our AI employs in-process monitoring, adaptive layer thickness, and controlled curing cycles. Each component undergoes inspection, with capability for holding tolerances to ±0.004″ on precision features.

What file formats do you accept for Carbon DLS projects?

We accept STL, STEP, IGES, X_T, Parasolid, SolidWorks, and other standard CAD formats. Our AI can also interpret GD&T callouts to ensure critical features meet specifications.