In hardware manufacturing, grinding machines play a pivotal role in shaping high-precision components for industries such as automotive, robotics, and consumer electronics, ensuring exceptional surface finishes and precise dimensional tolerances. These advanced tools are essential for producing durable, well-fitted parts that support the reliability of cutting-edge technologies, including electric vehicles (EVs) and renewable energy systems. For manufacturing teams, selecting the right grinding machine is a strategic decision that enhances productivity, minimizes scrap, and controls costs while meeting stringent quality standards. The following sections provide a comprehensive exploration of the primary types of grinding machines, their functions, and their significant impact across various industries.

What is a Grinding Machine? How Does it Work?

A grinding machine, commonly referred to as a grinder, is a tool used for metal finishing or other materials, which removes small chips with an abrasive wheel. This approach is typical in numerous manufacturing industries, particularly in instances where tight dimensional tolerances and fine surface finishes are required.

The machine basically spins a grinding wheel, presses the workpiece against it, and cuts away tiny bits of material. Grinding is generally a finishing operation, removing in the order of 0.25 to 0.50 mm in depth but attaining tolerances as fine as 0.000025 mm.

The core components of a grinder are the base, bed, headstock, tailstock, work table, spindle, feed mechanism, and the grinding wheel.

Precision vs. Volume

Precision grinding can provide extremely tight tolerances (as low as 0.000025 mm). High-volume grinding increases production but at the expense of surface finish. Whether to prioritize speed or precision varies based on the application and project requirements. Tool and cutter grinders are great at custom shapes but slower.

Precision grinders come into play where tolerance and repeatability count, like aerospace part manufacturing or high-end electronics. They really shine at work where a small error can affect performance or safety. Accomplishing these results frequently implies slower throughput, yet the rewards manifest in lower defect rates and higher product reliability.

Volume requirements factor directly into deciding which grinder to employ. If production is strong, surface or centerless grinders with automation assist accelerate workflows. These are machines that can process huge volumes efficiently, if a bit less accurately.

Energy use scales with machine class: surface grinders run at 2,000–5,000 watts, while cylindrical grinders need up to 10,000 watts.

Key Components and Their Functions

The grinding wheel serves as the primary cutting implement, employing abrasive grains to shear off material. The workpiece is gripped by the headstock’s chuck, which spins the piece.

At the same time, the spindle and feed mechanism regulate the motion and force exerted, maintaining uniform contact and sculpting. Fine adjustments are achievable with calibrated hand wheels or numerical controls that enable micro-level position changes.

Types of Grinding Machines

Surface grinders are great for flat surfaces, whereas cylindrical grinders work with round parts such as shafts. Centerless grinders operate without securing the piece in a chuck, rendering them suitable for mass production.

Tool and cutter grinders are employed for sharpening or creating intricate profiles. Each type is suited for a different niche and has its own compromises in price, pace, and skill.

Types of Grinding Machines

There are several types of grinding machines, all serving a particular purpose in contemporary manufacturing. They can be classified by movement of the workpiece or the grinding wheel. Some employ rotary grinding wheels, while others rotate the work.

This table provides a quick overview for reference:

|

Type |

Unique Features |

Common Applications |

|---|---|---|

|

Surface Grinder |

Magnetic chuck, flat grinding, high precision |

Tooling, die making, repair shops |

|

Cylindrical Grinder |

Rotating workpiece, CNC, complex contours |

Shafts, engine parts, aerospace |

|

Centerless Grinder |

No centers, dual rotary wheels |

Mass production, tubes, rods |

|

Internal Grinder |

Small bore, high-precision internal finish |

Gears, sleeves, bearing races |

|

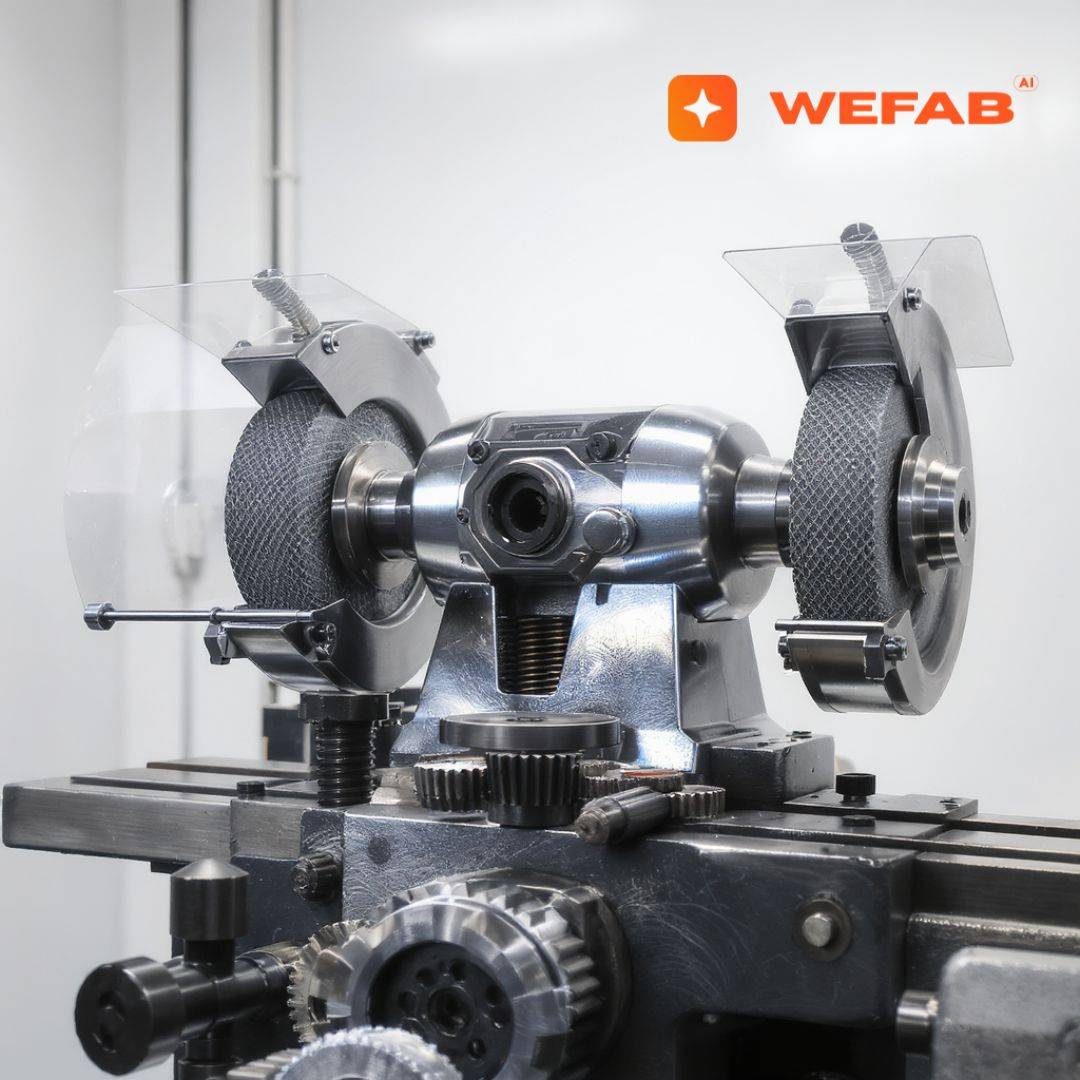

Bench Grinder |

Bench-mounted, dual wheels, general use |

Shop maintenance, tool sharpening |

|

Tool & Cutter Grinder |

CNC, 5-axis, multi-wheel |

Toolmaking, cutter shaping, regrinding |

|

Portable/Hand Grinder |

Handheld, flexible use |

Fieldwork, large parts |

1. Surface Grinders

Surface grinders form flat surfaces to close tolerances. By using a rotating abrasive wheel, they take off tiny shavings for a smooth surface. Magnetic chucks keep parts steady, increasing repeatability and speed.

These machines are heavily used in tool rooms and manufacturing lines, where flatness and finish count. Wheel selection—grit, hardness and type—affects both surface quality and tool life. Choosing the right wheel equals less reject and less down time.

2. Cylindrical Grinders

Cylindrical grinders concentrate on workpieces such as shafts, rollers, and sleeves. Workpieces rotated on centers or in chucks enable them to be ground uniformly along their length.

Automotive and aerospace industries rely on this technique for oil seals, pistons, and transmission components. CNC cylindrical grinders can operate on intricate shapes by means of pinch, peel and plunge grinding operations. Their tight tolerances and programmable paths make them indispensable for high-spec components.

3. Centerless Grinders

Centerless grinding bypasses the requirement for mounting centers. Instead, two wheels—one grinding, one regulating—hold and spin the work. Such arrangement slashes cycle times and increases output for small parts such as rods, tubes and pins.

Well known in mass production, centerless grinders excel in precision and fast for lengthy runs. The regulating wheel maintains the alignment of the part so that it is ground straight and size is controlled even at high volume.

4. Internal Grinders

Internal grinders operate inside bores, finishing the inner walls of cylinders, bushings and bearing races. Precision is key here for fit and function.

These machines often employ custom or small-diameter wheels to grind deep inside. Tools selection affects surface finish, roundness and cycle time. Internal grinding is essential to producing sophisticated components that require precise inner contours.

5. Specialized Grinders

Tool and cutter grinders, usually operating on 5-axis CNC platforms, fabricate and restore cutting tools. Their multi-wheel configurations enable you to profile drills, end mills and custom cutters in a single setup.

These machines evolve fast, appending sensors and automation for enhanced repeatability and reduced scrap. Specialized grinders provide versatility for niche requirements, like medical implants or aerospace fasteners, where conventional machines lack.

Facing Challenges with Precision Component Finishing?

Enhance efficiency with Wefab.ai’s grinding solutions, offering advanced CNC machining, reduced lead times, and high-quality finishes for automotive, robotics, and EV components.

Connect with Wefab.ai Today to Improve Your Production Precision!

Grinding in Modern Industries

From advanced robotics to climate tech, these grind systems trim, smooth, and shape parts at micrometer-level specifications. Modern grinding is about more than just abrasive. It’s about intelligent decisions, applying the appropriate method—surface, cylindrical, internal or tool grinding—to the task.

Technologies such as creep-feed grinding, operating at just 0.10 m/s, carved deep and slow for hardforms. Finish may be as fine as 0.2 micrometres. This detail translates into reduced defects, waste, and expense in multiple industries.

Climate Tech

Precision grinding for climate tech Wind turbine gears and solar panel frames require tight tolerances to function over years in harsh weather. Grinding machines assist in making these parts dependably, holding waste low as each part is formed to precise requirements.

Factories employ tool and cutter grinders for custom blades or pump components. Surface grinders create a flat, smooth surface for seals or connectors, minimising leaks and losses.

Because firms want sustainable processes, the newest grinding tech instead emphasizes efficiency and material savings. Optimized cutting paths, more efficient coolant application, and intelligent sensors all contribute.

A solar cell plant might employ internal grinding to craft small, high-efficiency connectors out of precious metals. By removing the material, waste decreases. These actions reduce both expenses and ecological footprint, demonstrating grinding’s role in the green transition.

Electric Vehicles

EVs require grinding for components such as rotors, stators and gear sets. These have to be precise, with tight specs — often within a few micrometers — to guarantee smooth, silent running.

There is cylindrical grinding for shafts and surface grinding to prep battery plates or frames. New grinding tools and automation accelerate EV manufacturing.

Others employ CNC-controlled grinders that change wheels for different metals without stopping the line. This reduced downtime and allowed factories to manage multiple part shapes.

This leads to quicker build and improved engine life. Accurate grinding keeps EVs running longer and safer by maintaining tight tolerances, even under heavy loads or heat.

Robotics

Robots require intricate components to operate properly. Grinding provides the smooth contours that joints, bearings and actuators need. Surface and internal grinding machines are frequently selected for these miniature, intricate components.

CNC grinding introduces more precision, allowing engineers to define precise parameters for every batch. In a plant assembling robot arms, automated grinders grind dozens of motor shafts an hour, inspecting each with sensors.

Together, this combination of intelligent software and professional-grade grinding translates to less grinding damage and more uptime. Good grinding ground parts stay longer on robots.

They minimize friction, maximize speed, and minimize fixes. That translates to sturdier robots in factories, hospitals, or remote locations.

Industrial Automation

Grinding forms essential automation components—spindles, guides, cams—with precision. On automated lines, robotic arms load and unload parts for grinding, eliminating labor and risk.

Automated grinding cuts process time. A line might employ tool grinders for machine knives, then surface grinders for flat plates. This flow keeps machines humming and components shifting.

Precision grinding keeps systems running without jams. Less downtime, more output. Intelligent grinding applications monitored by wear and notify operators in advance of breakdown.

Achieving Precision Machining

Precision machining is the heart of high-tech manufacturing, allowing companies to churn out superior parts that adhere to demanding specifications. Grinding machines help us achieve tolerances as tight as +/- 1.3 microns for diameters and surface finishes to 0.2 microns. This level of precision is critical in robotics, EVs, and aerospace, where even the smallest imperfection can cause expensive malfunctions.

As requirements for tighter tolerances and improved finishes increase, grinding process and equipment innovations are transforming past pains, such as material inconsistency and uneven finishes, into obvious opportunities for quantifiable gains.

Material Selection

Material selection is key in precision grinding. Each alloy presents its own challenges. Hardness, ductility and thermal conductivity govern how the workpiece interfaces with both the abrasive and the machine. Grinding hardened tool steel, for example, requires distinct abrasive grit than softer aluminum.

Abrasive choice—alumina, CBN, or diamond—affects not only removal rate but heat buildup, which may produce microcracks or surface burns if not suited to the workpiece. Harder materials grind slower but create finer finishes. Softer metals can load the wheel and lose precision.

Wheel Selection

Choosing the right wheel is about matching grit size, bond type, and wheel structure to the job. Coarse grits cut quickly but can leave a rougher finish, while fine grits impart the polished smoothness required on sealing faces or bearing journals.

Bond type–vitrified, resin, metal–impacts heat resistance and wheel life. The right wheel keeps geometry and finish consistent, particularly in centerless and cylindrical grinding where tolerances range in the microns. A wrong wheel can cause rapid wear, chatter and surface defects, creating scrap and rework.

Operational Parameters

-

Wheel speed: Higher speeds can improve material removal but raise heat risk.

-

Feed rate: Fast feeds speed up cycles but may reduce finish quality.

-

Depth of cut: Removing 0.25–0.50 mm at a time maximizes control and accuracy.

-

Coolant flow: Proper cooling prevents thermal distortion and burns, critical for tight tolerances.

Thoughtful tuning of machining parameters allows machinists to achieve desired tolerances and optimize productivity in machine technology. Real-time monitoring and AI-based controls, like those in the Wefab.ai platform, help fine-tune these settings for each run, reducing cycle times and defects.

Machinery and AI Integration

Grinding machine innovations—such as CNC and adaptive control—have set a new standard for precision. CNC grinders hit tolerance bands of +/- 0.000025 mm, allowing for complex geometry parts for climate tech and automation.

Platforms such as Wefab.ai use AI for DFM, automated inspection, and process optimization, serving cost, quality, and supply chain transparency in one platform.

Need Expert Support for Grinding Operations?

Partner with Wefab.ai’s specialists, providing AI-driven optimization, safety protocols, and real-time tracking to elevate your grinding accuracy and efficiency across industries.

Contact the Experts at Wefab to Streamline Precision Machining Operations!

Operator Safety and Best Practices

While grinding machines can increase efficiency and quality in metalworking, they introduce tangible dangers if not handled properly. Safety guidelines, consistent inspections and diligent workspace organization are imperative to reduce accidents and facilitate adherence to international regulations.

Below is a checklist for safe grinding machine operation:

- Wear all necessary PPE – goggles, gloves, hearing protection, protective clothing.

- Check your machine prior to each use, especially the wheels and lubrication.

- Test new or refitted grinding wheels for one minute prior to use.

- Keep the work area clean, organized, and well-ventilated.

- Perform grinding risk assessments, identify hazards, record findings, and implement control measures.

- Monitor noise and dust exposure, and enforce the limits: 85 dB for noise, 10 mg/m³ for E-dust, and 1.25 mg/m³ for A-dust.

- Limit daily vibration exposure per regulatory requirements.

- Apply tools and abrasives suited to machine speeds and specific applications.

Personal Protection

PPE is your first line of defense when operating grinding machines. Nearly every country mandates employees to supply approved protection, as exposure to wear is a serious concern. This includes safety goggles to protect eyes from gritting debris, gloves to minimize abrasion and vibrations, and hearing protection to curb noise during operations with machines like cylindrical grinding tools.

Goggles and gloves are essential! Grinding generates micro-debris at high velocity that can inflict permanent eye injury or skin lacerations in seconds. Gloves also help minimize direct contact with sharp metal workpieces and tool kickbacks, enhancing safety.

Hearing protection is important too, as grinders can often exceed 85 dB, and prolonged exposure at this level poses a risk of permanent loss. Operators should wear protective clothing—long sleeves and flame resistant fabrics do a good job shielding against sparks and hot metal chips.

Not only is this best practice, it’s a pragmatic move to prevent burns and embedded metal shards.

Machine Inspection

Regular inspection is the secret to safe operation. Every morning take a visual inspection of the grinding wheel for cracks, chips, and wear, as well as confirmation that guards and shields are in place.

Operators need to inspect wheel mounting, backup pad condition and all safety interlocks. Lubricating the moving parts is essential — it keeps the spindle running smooth and prevents heat buildup that can cause failure.

Decent inspections assist catch issues ahead of time. Small cracks or imbalance in a wheel can become fatal hazards. Periodic inspections prolong the equipment’s lifespan, reducing downtime and repair expenses for the company.

Work Area Safety

A clean, well-organized work space isn’t just good for efficiency — it’s essential for safety. Clutter adds tripping hazards and can obstruct emergency stops or fire extinguishers.

Grinding produces dust, sparks and noise. Dangers consist of flying chips, tool kickbacks, and potential fire. Keeping combustibles out of the work zone, delineating safe walkways and posting hazard signs all reduces risk.

Proper ventilation distributes dust and fumes, assisting in maintaining them within safe levels. This is key for compliance and for operator health, as fine dust can lodge deep in lungs or even enter the blood stream.

The Future of Grinding Technology

Grinding machines are evolving rapidly, with modern grinding technology incorporating automation, AI, and sustainable design to enhance precision machining. As companies demand tighter tolerances and faster lead times, the need for high surface quality and efficient machining operations is more crucial than ever. This evolution in machine technology enables advanced machines to keep pace with industry requirements for greener production and precise grinding.

AI and digital tools now connect grinding machines to the entire shop floor, facilitating smooth cut operations and allowing data to flow seamlessly, which helps resolve issues before they lead to downtime.

AI Integration

AI is transforming modern grinding technology now. It assists machines in making intelligent decisions—modifying spindle speed, pressure, and cooling according to real-time information. Machine learning detects patterns in tool wear and triggers service when necessary, ensuring breakdowns are infrequent and schedules remain on target.

AI-driven analytics display which steps in the machining operations consume the most time or energy, simplifying the adjustment of settings for improved parts and reduced scrap. AI assists with training. Operators navigate through crystal-clear, contemporary interfaces that guide them through a series of steps — getting complicated set-ups done quicker and with more confidence.

In high-mix, low-volume runs, AI can auto-tune machines to new specs without large standstills. Take an EV battery plant, for instance – there, AI software can detect a surface finish drift and correct it before the part breaks inspection.

Energy Efficiency

|

Innovation |

Sustainability Impact |

Example Use Case |

|---|---|---|

|

High-efficiency motors |

Lower energy draw |

Robotics parts shops |

|

Dry grinding techniques |

Less fluid waste |

Consumer tech plants |

|

Closed-loop filtration |

Reuse of coolants |

EV battery casings |

|

Real-time energy tracking |

Quick waste fixes |

Industrial automation |

Energy efficiency is now at the forefront. More efficient motors and drives reduce power consumption in machines, and closed-loop systems minimize new coolant requirements, thereby decreasing cost and waste.

Dry grinding whenever possible means no fluid at all—a huge victory for both the planet and the bottom line. These measures make grinding less expensive and more sustainable. They furthermore assist corporations to comply with stringent green regulations, now an imperative for worldwide supply chains.

Advanced Materials

New materials such as nanoceramics and superalloys require superior grinding instrumentation. Superabrasives like CBN and diamond are now standard for these tasks—they grind faster and last longer than vintage wheels. That translates into finer tolerances and finer finishes, even on components that were once too hard or brittle for conventional grinding.

New materials force manufacturers to reconsider wheel design. Innovative bonds and grain shapes mean wheels stay sharper, longer, reducing downtime and increasing part quality. Research doesn’t stop either, with labs and OEMs experimenting with new mixes that play nice with the newest high-tech materials.

The demand for ongoing R&D is intense. With each new alloy or ceramic, grinding has to keep pace or be left behind as customers demand ever higher.

Industry Impact

High-tech grinding to aid EV, robotics, green energy. These industries require complicated shapes and exceptional finishes that only advanced grinding can provide.

Wefab AI brings these gains to clients worldwide, as AI-first contract manufacturing to offer CNC machining and grinding for better finishes and faster lead times. With Wefab’s services, businesses can receive real-time tracking, predictive defect checks, and cost savings—addressing old pain points in speed, quality, and transparency.

Conclusion

Grinding machines encounter grand challenges in contemporary labor. Expensive and difficult to locate skilled workers along with downtime damaged both production and profitability. Missed specs and bad finishes drag projects and increase waste. These spaces compel teams to seek new methods to operate more rapidly and securely. New tech, like smart sensors and AI, now ramp up speed and hold errors down. With these innovations, crews hit hard specs and trim waste. Intelligent arrangements assist stores to stay in step and build confidence among consumers. Wefab AI assist teams to leverage these advantages for genuine outcomes. Prepared to go deeper? Check out Wefab.ai and receive an immediate quote now!