A DLP 3D printer produces a 3D creation through a series of high-quality, pixel-by-pixel digital photo patterns. It does this by using a digital light source to cure liquid resin. Unlike FDM printers that build layer by layer using filament, DLP printers project an entire layer of light onto the resin, curing it simultaneously.

This approach is perfect for detailed models, providing high-resolution textures and clear-line details. DLP printers tend to be popular in jewelry, dental, and product prototyping industries. They provide much quicker print speeds compared to SLA printers thanks to their exposure process that exposes each layer at once.

With advancements in materials and resolution, DLP technology has become a go-to choice for professionals needing accuracy and speed in small to medium-sized prints.

What is DLP 3D Printing?

Digital Light Processing (DLP) 3D printing technology is a powerful, precise, and productive additive manufacturing method. It utilizes a digital light projector and ultraviolet light to turn liquid photopolymer resin into solidified real-world objects. At its core, the 3D printing process emphasizes high accuracy and cost efficiency, providing real, practical advantages to sectors that require highly detailed prototyping and short-run production with various applications.

DLP printers operate much more quickly than conventional SLA printers, thanks to their ability to cure entire layers of resin simultaneously. This maximizes productivity potential while delivering enhanced print accuracy. DLP 3D printers are now available at entry-level price points starting at $4,999, allowing more people to get involved without sacrificing quality.

1. Core Principle: Projecting Digital Light

At the very core of DLP printing is the digital light projector. It automatically projects UV light at a 385 nm wavelength in layers directly onto the resin surface to create your build. This light triggers photopolymerization, a chemical reaction that solidifies the resin into exact forms.

Carefully controlled light projection guarantees uniform layer solidification, allowing for the creation of highly intricate and precise prints.

2. The Micromirror Device (DMD) Role

The digital micromirror device (DMD) is a critical component, manipulating light using thousands of tiny mirrors to project intricate patterns. This proprietary technology optimizes for maximum speed and resolution at the same time.

Achieving crisp, detailed prints full of accuracy is the result of this advanced technology.

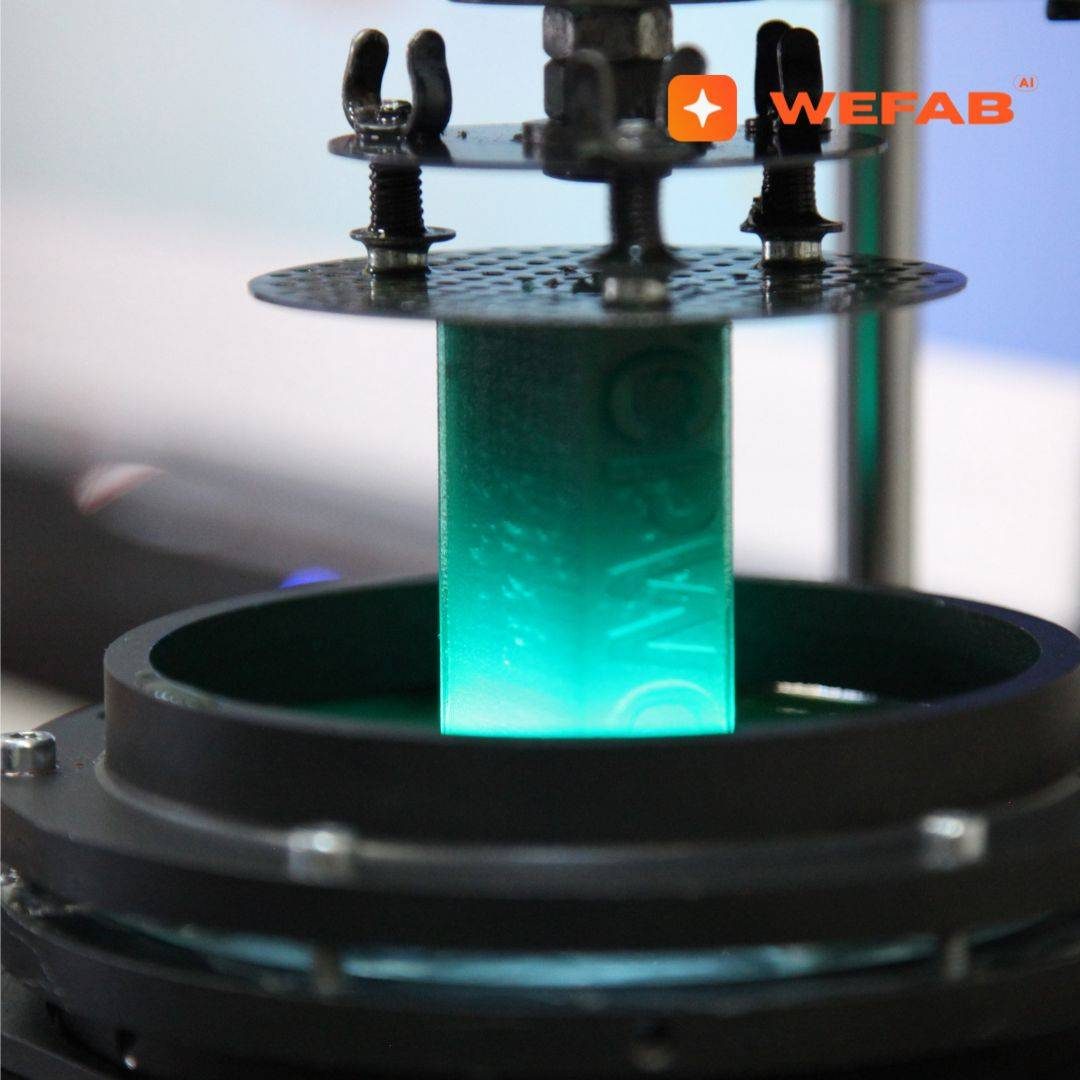

3. Understanding Vat Photopolymerization

Vat photopolymerization, a process where light is used to cure resin, serves as the basis for DLP printing. A UV light source cures the photosensitive resin in a precise vat, creating durable prototypes layer by layer.

This technique is very effective at creating highly complex parts with excellent resolution and surface quality.

4. How Layers Form Instantly

DLP 3D printing technology’s unique capability to cure whole layers in one go, rather than individually curing areas, significantly enhances printing speed. This high efficiency makes DLP printing perfect for projects where time is of the essence.

5. Essential DLP Printer Components

Essential parts of a dlp 3d printer include the resin vat, build platform, light source, and peel mechanism, all crucial for achieving high print accuracy and quality prints.

6. Unique Aspects of DLP Technology

The speed, precision, and versatility of DLP 3D printing technology set it apart, as it supports various materials, making it invaluable for industries ranging from robotics to climate tech.

DLP vs. Other Resin Printing Methods

Resin-based 3D printing technologies like DLP 3D printing technology, SLA, and LCD offer unique benefits, but the right choice depends on specific project needs. Understanding how they vary in speed, resolution, and cost will help users select the best DLP solution for their 3D printing process.

Comparing DLP and SLA Technologies

DLP 3D printing technology and in their approach to curing resin. DLP utilizes a light projector to cure an entire layer at the same time, making it ideal for high print speed. In contrast, SLA uses a focused laser to draw and cure the resin layer by layer, which results in exceptional precision for intricate designs.

This difference means DLP is much faster, especially with larger builds. The DLP 3D printer’s unique 385 nm UV light source ensures compatibility with a variety of DLP materials, providing unprecedented capabilities for any project you desire. This versatility in material choice enhances the overall 3D printing process, allowing for more innovative applications.

SLA shines when it comes to ultra-high-resolution finishes due to its precision laser, making it a great choice for detailed and complex designs. These differences in curing speed and print accuracy immediately affect which applications each method is suitable for.

Production DLP increases production efficiency through its pace, making it a strong contender for low volume manufacturing. Conversely, SLA excels in applications where surface finish must be outstanding, such as in dental and jewelry models. Users need to weigh these trade-offs based on their specific project requirements.

Distinguishing DLP from LCD Printing

While conceptually similar, DLP and LCD printing execution is different. LCD printers take advantage of an LED array paired with an LCD screen to block light, curing entire layers in a fraction of a second.

DLP shines light through an array of micromirrors, producing a more even cure. This distinction affords DLP a minor advantage in the areas of resolution and variety of materials. The 385 nm light wavelength that DLP uses opens up a greater range of resin options than other technologies.

Compared to LCD, the 405 nm light source is more versatile.

Key Differences Summarized Simply

- Speed: DLP and LCD are faster than SLA.

- Resolution: SLA offers finer details. DLP achieves the ideal mix between speed and precision.

- Cost: LCD is typically more budget-friendly than DLP or SLA.

Key Advantages of Using DLP

Digital Light Processing (DLP) 3D printing technology has become one of the most powerful mediums in 3D printing. It provides unparalleled benefits that appeal to the passions of professionals and hobbyists alike. DLP employs a distinctly different method of curing photopolymer resins. This provides industry-leading print accuracy, speed, and flexibility, making it the technology of choice across the industry spectrum.

Achieving Faster Print Times

One of the areas where DLP printers really shine is in their sheer speed. In contrast to other additive techniques which print designs by outlining each layer, DLP reaches usual speeds of up to 0.98 inches/hour. This increased efficiency means projects get completed much quicker allowing industries to operate at full productivity even during short timeframes.

For example, rapid prototyping in robotics manufacturing benefits significantly from reduced cycle times. This allows teams to iterate designs quickly without compromising accuracy.

Producing High-Resolution Details

An ability to manufacture detailed, complex geometries of great resolution is a key characteristic of DLP technology. Resolutions can make it to 60% of the original design. This enables use cases such as jewelry creation and dental modeling with unrivaled precision and smooth surface finish.

These highly accurate results mean engineers and designers can trust DLP for large scale, complex geometries and exacting tolerances.

Ensuring Stronger Part Durability

DLP’s UV polymerization technology, utilizing high-quality DLP materials, produces strong, durable parts with isotropic mechanical properties. This makes it perfect for functional prototyping and end-use applications in various industries. Whether in service to industrial automation or to enable climate tech, DLP printing provides robust products that perform in the rigors of everyday use.

Expanding Material Options

DLP 3D printing technology offers the advantage of supporting a wide array of DLP materials, enabling flexibility in both mechanical and aesthetic properties. From low-cost LCD 3D printers to the latest proprietary material advancements, the opportunities to customize are limitless.

Is Your Prototyping Process Slowing Down Your Time-to-Market?

Get Unmatched Precision and Speed for Your Automotive Projects!

Understanding DLP Limitations

Digital Light Processing (DLP) 3D printing technology provides an unmatched level of detail and speed, particularly when using tough DLP materials. To realize its full potential, users need to be aware of its limitations. By proactively understanding these limitations, you can account for them in your decision making and better equip yourself to choose DLP solutions that fit your project’s vision and your organization’s priorities.

Considering Build Size Restrictions

DLP printers tend to have smaller build volumes because of their fixed XY resolution, which usually falls between 35 and 100 microns. This limitation arises from the micromirror devices count, as well as the size of the build area.

On the bigger designs, it becomes practical to make segmented designs which can impact strength and build time. Alternatively, complicated prototypes in fields such as robotics might need to split components into sub-components, doubling post-processing efforts.

Incorporating plans for this at the design stage makes it easier and more cost-effective while minimizing mistakes.

Addressing Potential Pixelation Effects

Pixelation starts when the printer’s resolution and details of the surface are not compatible, resulting in obvious stripes or layer lines. This effect has an even greater impact on non-linear or complex shapes and curvilinear designs.

By changing resolution settings and using higher-quality resins, this can be mitigated, leaving you with nice, smooth finishes. For example, the Form 4 printer’s advanced settings, paired with its 98.7% success rate, provide reliable solutions for demanding applications like industrial automation parts.

Evaluating Initial Investment Costs

Although DLP printers come with an increased cost up front, their fast print times and exact detail usually lead to overall savings in the long run. A fleet of fast printers like the Form 4 can rival injection molding in throughput, making it cost-effective for small-batch production.

Establishing a maintenance budget, which accounts for regular maintenance and replacement of resins and bulbs, is important for prolonging DLP performance.

Projector Bulb Lifespan Impact

The longevity and quality of projector bulbs have a direct impact on print uniformity. Frequent replacements not only incur additional operational costs, but avoiding replacement may compromise safety, so durable components are critical to design.

Quality bulbs are important to deliver curing at the correct wavelength of 385 nm for consistent and quality output results.

Optimizing Your DLP Prints

Bringing together the unmatched accuracy and speed of DLP 3D printing technology, this process is the perfect fit for hardware innovators. Achieving high print quality and speed requires understanding the most important factors, optimizing your settings, and keeping your DLP 3D printer in peak condition.

Factors Controlling Resolution and Speed

Resolution and speed are both contingent on various parameters, such as layer thickness and exposure time. Adopting thinner layers can make for wonderfully detailed prints that increase print time, whereas thicker layers are generally faster, sometimes sacrificing detail in the process.

Exposure time makes a major impact here. For example, using UV light at 365 nm and intensity with 2.7 mW/cm² for 2.6 seconds will provide a customized layer thickness. Hydrogel systems and optics are powerful allies to improve results. They provide resolutions as detailed as 0.001 inches and speeds from 0.02 to 0.6 inches per second.

Finding a happy medium between these two settings will serve you best.

Light Source Quality and Accuracy

Quality of the light source especially is critical. Changes in intensity or wavelength of UV can affect curing accuracy. For instance, 385 nm UV light cures most resins efficiently.

At the same time, the 380 nm UV source at 100 mW/cm² produces clear, high-precision, repeatable prints across the entire vat. Better print quality with precise light control reduces imperfections, making prints more reliable and consistent.

Solving Common Print Failures

Adhesion failures, layer shifting, and voids are common problems. To fix adhesion, level the bed and resin viscosity, whereas the most common source of layer failures are incorrect exposure times.

A detailed knowledge of your printer settings can help prevent these issues.

Best Software and Slicing Choices

With easy-to-use interfaces, slicing software such as Chitubox makes it easy to streamline your workflow. Optimizing peeling parameters, adding supports, and determining a proper infill density will increase structural integrity.

Wefab.ai connects perfectly with those systems, with our AI-powered platform helping you refine your processes and speed your timelines.

Exploring DLP Resin Materials

DLP 3D printing technology relies heavily on the choice of DLP materials, which dictate both print quality and the functional properties of the final part. This technology, which uses a light projector to cure liquid photopolymer resin layer by layer, achieves remarkable speed (up to 0.98 inches/hour) and precision defined by pixel size in XY resolution. The resin you select can have a profound impact on all of these factors.

Choosing Compatible Resins Wisely

Understanding the relationship between your DLP printer and resin is key. Each printer is factory-calibrated for specific resin formulations, producing perfectly uniform and accurate light curing, and thus mechanical stability. Incompatible resin usage can lead to poor adhesion, diminished accuracy, or outright failed prints.

Become familiar with the available resin options to improve the functional and aesthetic appearance of your print. This choice allows you to fully realize DLP’s high resolution and speed.

Standard Resins for General Use

Standard resins are multipurpose and best for prototypes or visual models. They provide well-rounded mechanical properties and smooth surface finishes. This versatility renders them perfect for a variety of applications, from product design to educational aids.

When you know their physical properties, like moderate tensile strength and low brittleness, you can be confident they will perform under your project’s unique requirements.

Tough Resins for Functional Parts

Tough DLP materials provide high durability and impact resistance, making them ideal for functional prototypes or end-use parts in 3D printing technology. Industries such as automotive and robotics utilize these materials, where strength and toughness are of utmost importance.

Flexible Resins for Elasticity

Flexible resins, a key component in dlp 3d printing technology, are ideal for applications that require elasticity, such as seals or wearables, providing invaluable resources for producing soft, pliable components.

Struggling to Meet Strict Automotive Quality Standards?

Ensure every part is perfect with Wefab.ai’s AI-powered CNC platform, providing automated quality control, material optimization, and expert insights for your manufacturing workflow.

Transform Your Automotive Manufacturing with AI-Driven Precision!

Essential DLP Post-Processing Workflow

Post-processing is an important step in DLP 3D printing, when the raw prints are processed to give them a professional quality finish. This three-part procedure turns raw builds into highly detailed, usable parts by improving the nature of the surface characteristics, strength, and appearance.

Whether it’s cleaning, supports, or curing, it’s important to understand that each step is necessary to create a final product that matches your original design.

Cleaning Prints Thoroughly

Once prints are removed from the build platform, careful cleaning is imperative to ensure no leftover resin remains which could cause defects. Submerge the print in isopropyl alcohol (IPA) or another solvent and agitate carefully to dissolve any excess material.

The use of soft brushes or ultrasonic cleaners can help further preserve delicate detail without risking the stability of the printed item. This step makes sure that the final curing process is repeating good performance results, bringing both better looks and lasting durability.

Final Curing Importance

In addition to finalizing the print’s mechanical properties, curing deepens the print’s surface finish. UV light exposure, customized to the resin type in use, is instrumental to producing quality results.

Consider the curing time which can make a range from seconds to minutes per layer based on your material and printer specs. Maximizing precision is paramount in controlled environments with consistent, uniform UV exposure.

Think of medical devices or high-tolerance parts, for instance.

Removing Support Structures Cleanly

Whether breakaway, soluble, or incisable, careful removal is important to preventing unsightly blemishes and ensuring the dimensional accuracy of prints. Precision tools, like flush cutters or fine tip tweezers, greatly reduce chances of damaging.

Methods such as heating or resin softening are additional helps to make clean removals, notably for complicated geometries.

Achieving Optimal Surface Finish

Post-processing processes like sanding, polishing, or spraying with a clear coat are essential to enhance the smooth surface of 3D prints. To achieve the best final product, Wefab.ai’s AI-powered platform optimizes the 3D printing process to ensure accuracy and efficiency during each post-processing step.

DLP Applications and Future Potential

DLP (Digital Light Processing) technology has emerged as a foundation in sectors where intricate design and high accuracy in production are paramount. This new technology turns liquid resin into highly-detailed, aggressive, three-dimensional parts. It’s able to achieve layer resolutions as fine as 0.001 inches, transforming the production of highly-detailed parts.

Industries such as robotics, healthcare, and automotive are using its precision for both rapid prototyping and low-volume production. Applications include lattice structures, hollow designs, and functional parts with exceptional surface finishes, meeting demands for geometrically complex and high-quality outputs.

Rapid Prototyping Advantages

DLP speeds up design iterations by curing complete resin layers at once, offering rapid turnaround times while maintaining high resolution and precision. This new capability allows for more iterative design cycles, freeing engineers to iterate on products faster.

In the real world, robotics companies are using DLP to quickly prototype end-effectors with complex geometries. The medical field utilizes DLP for producing tailored and accurate surgical guides.

Wefab.ai streamlines this process even further by leveraging AI to provide instant quotes and optimized workflows, delivering quicker design-to-prototype turnaround times.

Viability for Low-Volume Manufacturing

DLP’s cost-effectiveness with small production runs makes it a perfect fit for startups and more specialized industries. Its modular design allows for custom material characteristics like heat resistance to 392°F, making it versatile.

Climate tech companies, for instance, use DLP to create sensor housings that need to withstand harsh environments while still delivering highly sensitive measurements. Wefab.ai’s platform takes things even further by uniting smart manufacturing with next-level scalability.

Exciting Emerging Industry Uses

Emerging fields such as bioprinting and custom industrial manufacturing see potential in DLP 3D printing technology for uses ranging from tissue scaffolds to custom industrial components. With research into advanced resin chemistries and DLP materials underway, even greater innovation lies ahead.

Conclusion

DLP 3D printing leads the way when it comes to achieving precision, speed, and versatility for producing detailed parts. This technology guarantees precise edges, smooth surfaces, and extreme details. Its high precision and accuracy make it popular in industries including healthcare, automotive, and consumer goods. From prototyping through end-use functional parts, results consistently yield exceptional detail and performance – especially when used with the appropriate resin and optimally calibrated settings. As with all technology, it has its quirks, and when handled correctly through the appropriate post-processing, one can unlock the full potential. Whether you are scaling up production capacity or experimenting with new materials, DLP provides tangible and proven solutions to bring your ideas to life.

Want more info on getting started? Check out Wefab.ai and receive a quote within minutes today!