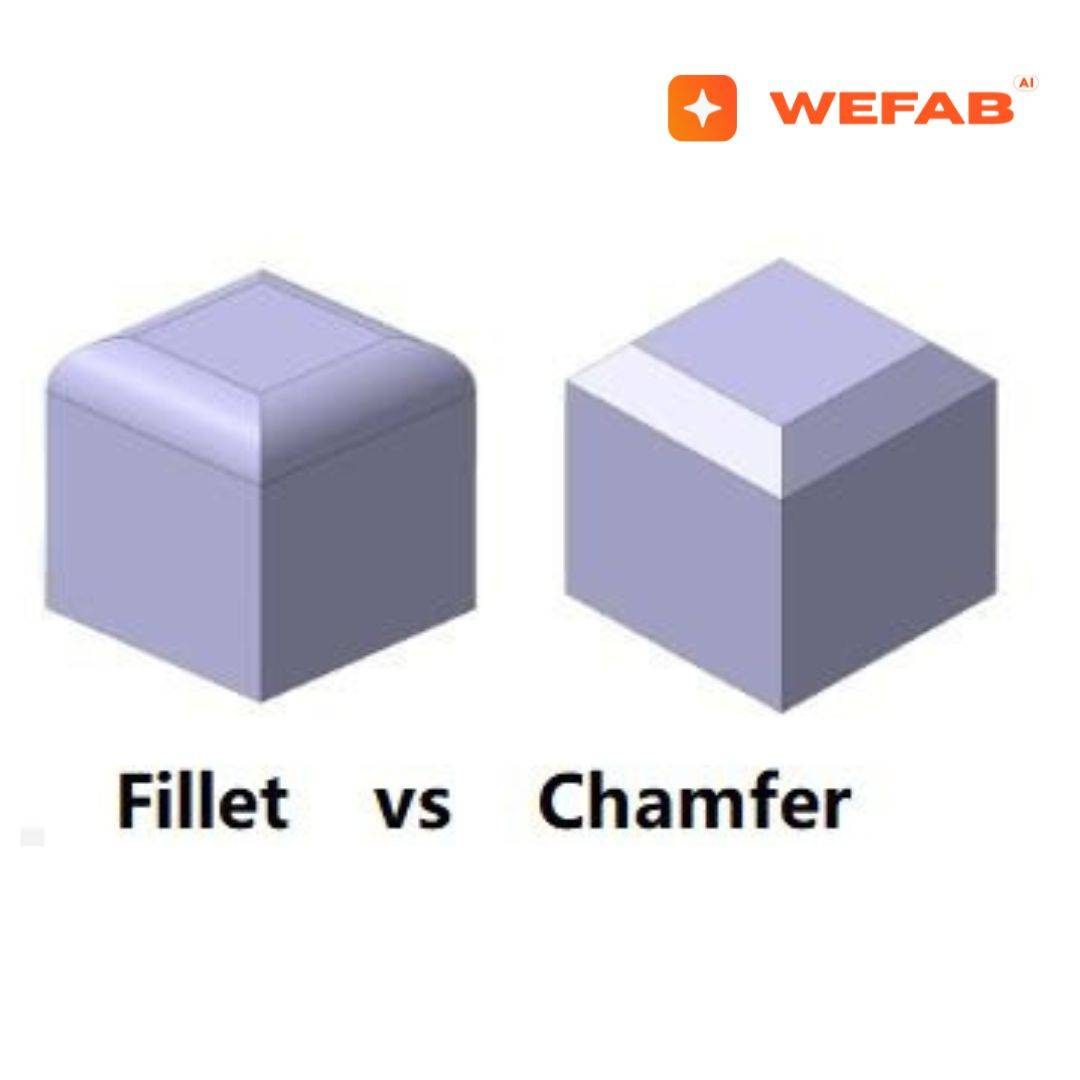

In 3D printing, selecting the appropriate edge treatment—chamfer vs fillet—is a critical decision that impacts both the functionality and aesthetics of printed parts, particularly in industries such as climate tech, robotics, electric vehicles (EVs), and consumer hardware. Chamfers, with their angled edges, and fillets, featuring smooth, curved transitions, each offer distinct advantages depending on design goals, material properties, and manufacturing constraints. This choice influences stress distribution, printability, and post-processing requirements, making it essential for designers to understand their applications. The following sections provide a detailed comparison of chamfers and fillets, their practical uses, and expert guidance to help you optimize your 3D-printed designs.

The Fillet vs Chamfer Dilemma

The fillet vs chamfer dilemma has an impact on the aesthetics, utility and mechanical advantage of machined and molded parts. While both types of treatments smooth sharp edges, they vary in geometry, intention and application. They influence everything from stress tolerance to assembly time.

The following table shows the core geometric differences:

|

Feature |

Fillet |

Chamfer |

|---|---|---|

|

Shape |

Rounded (arc) |

Flat, straight (bevel) |

|

Typical Angle |

Curved, no fixed angle |

Often 45°, can vary |

|

Application |

Corners/junctions |

Edges/surfaces |

|

Example |

Bearing housings |

Screw lead-ins |

1. Geometric Profile

Fillets are soft, curved transitions which blend surfaces, whereas chamfers are linear, angled cuts typically at 45°, but occasionally other angles in order to fit the design. The rounded transition of a fillet lessens hard surface shifts, which makes parts easier to clean and less likely to snag.

Chamfers, with their sharp, angled faces, establish crisp edges and can aid in guiding parts together, especially in assemblies. That geometry affects how parts fit and move against one another. Mating parts that slide or rotate often employ fillets to minimize wear.

Chamfers, on the other hand, play nicely on components requiring crisp alignment stops or where visual definition is desired. For instance, robotic gripper jaws are frequently filleted on internal corners for strength, but chamfered on outer edges for quick sensor alignment.

2. Stress Distribution

Fillets distribute mechanical loads across a broad region, thereby reducing stress concentrations which cause cracks. This is especially critical in load-bearing parts such as gear teeth or brackets. Chamfers eliminate sharp corners, reducing stress risers, but not as effectively as fillets.

For printed parts, particularly in high-impact or fatigue-prone assemblies, fillets add life. Chamfers are helpful for non-loaded parts, or when easy handling is more important than maximum strength.

3. Aesthetic Appeal

Fillets have a product more of a ‘soft’, organic appearance, which you see often in consumer electronics or medical products. Chamfers provide a more technical, precise look, preferred in aerospace and industrial equipment.

Visual decisions influence product desirability. A lot of tech gadgets are all fillet because they should be sleek and safe, but a lot of tools and connectors receive chamfers because they need to feel tough and engineered.

Fillets are comfortable in car interiors and chamfers signify a functional zone or control. The sweet spot is between function and aesthetics.

4. Functional Purpose

Fillets are safer (less injury risk), cleaner (easier to wash), and more durable (less chipping). Chamfers speed assembly by directing screws or dowels, and are adaptable—one bit can do lots of sizes.

Edge treatment can make or break part function. A 0.254mm chamfer at 45° is a typical hack for bolt lead-ins. In a single EV battery housing, for example, the switch to filleted corners increased impact resistance by 12%.

Edge finishing, either by cutting or grinding, assists in deburring any drilled holes, making them fit better and safer.

5. Assembly Aid

Chamfers are great for guiding pins, shafts, or fasteners when assembling, particularly on automated lines. They ease insertion and prevent jamming. Fillets generate transitions that allow components to slide by one another with less friction.

A lot of assembly headaches result from missed edge breaks. Designers can sidestep this by explicitly calling out chamfer or fillet types and sizes on drawings.

For fast builds or high-mix runs, chamfers help save time by making parts easier to orient. Using a combination of both, selected by function, frequently yields the best outcome.

Implications for 3D Printing

Fillets and chamfers are about more than just defining part aesthetics in 3D printing; they influence success rates, print speed, and durability. Edge finishing influences material flow, warping, and structural integrity. Designers should consider every decision up front, since print process, material, and geometry each contribute to whether a part satisfies functional and aesthetic requirements.

Choosing the optimal edge style can translate to less wasteful prints and less post process, enabling quicker iteration and greater part quality overall.

Overhangs

Chamfers help control overhangs by substituting abrupt right angles with easily printed sloping surfaces. This boosts print success since anything over 50° that’s unsupported is going to fail except on expensive machines. Fillets, in addition to relieving stress and enhancing strength, have a tendency to form curved overhangs that typically require additional support, thereby increasing print duration and post-processing efforts.

The trick is to leverage chamfers on exposed edges where support is difficult to extract, and fillets where stress relief is crucial. To reduce support structures, don’t bridge over 10 mm unless your printer and material can traverse longer distances. Good edge planning results in higher print quality, less cleanup, and greater visibility into production.

Layer Adhesion

Edge treatments impact layer adhesion. Fillets contribute surface area at layer interfaces, inducing stronger parts and less chance of delamination, particularly in curved or load-bearing zones. Chamfers would likely reduce that bonding area, thereby making some sections weaker if not designed with enough thickness.

To make the most effective parts, round internal corners with fillets and maintain wall thickness > 0.9 mm. This mix adds durability and reduces component fracturing, which is crucial for either functional prototypes or final-use parts.

Print Time

Complex fillets increase print time, as the printer needs to outline fine curves at every layer. However, chamfers have straight edges, resulting in fewer moves and retraction. Selecting chamfers on non-critical edges can accelerate manufacturing by a significant amount.

Designers should balance the requirement for smoothness against the need for speed, selecting detailed fillets only where they are important for fit or function. This maintains lean schedules without sacrificing quality in important places.

Resolution

The finer the fillet, the greater the resolution needed, which calls for longer print times and carefully optimized machine parameters. Sharper chamfers are simpler to realize even at low resolutions, but may not resemble the target or dissipate stress as well.

If embossing or engraving, maintain details over 2x the nozzle diameter deep for crisp, professional effects. Material selection plays into resolution—brittle plastics can chip at sharp chamfers, while flexible ones better embrace fillets.

Struggling with Edge Design Challenges in 3D Printing?

Optimize your parts with Wefab.ai’s expertise, offering tailored fillets and chamfers for enhanced strength and assembly in robotics projects.

Collaborate with Wefab.ai Today to Improve Your Design Efficiency!

How Do Edge Treatments Like Fillets and Chamfers Affect a Part’s Structural Integrity?

Edge treatments such as fillets and chamfers directly affect the way parts resist loads, friction, and fatigue. Their application affects not only the flow of forces through a part but its durability, quality, and behavior in practical environments. Below is a summary comparing the impact of fillets and chamfers on structural integrity:

|

Edge Treatment |

Stress Reduction |

Fatigue Resistance |

Impact Strength |

Common Use Case |

|---|---|---|---|---|

|

Fillet |

High |

High |

High |

Bridges, shafts, molds |

|

Chamfer |

Moderate |

Moderate |

Low-Moderate |

Gear teeth, electronics |

Stress Concentration

Sharp corners are excellent locations for stress concentrations, particularly where two surfaces intersect at acute angles. Even modest loads can provoke cracks to initiate here. Fillets assist by rounding out the connection between surfaces, which distributes the load over a larger area and reduces stress concentrations.

This can prevent cracks from initiating and maintain components from fracturing under extreme stress. For high-load applications—consider bridge beams or robotic arms—maintaining stress below a threshold level in corners is critical. Fillets are de rigueur here.

In car suspension arms, replacing hard corners with fillets has slashed failure rates and increased service life. Designers can apply stress analysis to select the appropriate edge treatment. For small clearances, a small fillet can still do a lot of good.

When employing chamfers, choosing the proper angle and scale is important. Large chamfers reduce stress but may compromise the part’s strength.

Fatigue Resistance

When components see cyclical stress, fillets provide them a better chance at surviving longer. They allow stress to flow freely, so cracks have less opportunity to propagate over time. In the aerospace world, fillets appear in turbine blades, and they show up in brackets — they’re used to increase fatigue life.

Chamfers don’t compete with fillets for fatigue, particularly under cyclical conditions. They assist in assembly and can thereby relax some stress risers. However, sharp chamfers may not distribute load optimally.

The proper combination of material and edge treatment is critical. High-strength alloys with ample fillets perform best for gear teeth or crankshafts. Field studies demonstrate that fillets in train wheel axles or wind turbine hubs can increase their fatigue life by a factor of two over chamfered or sharp edges.

Impact Strength

Edge treatments impact how parts absorb hits as well. 3D printed pieces, for instance, can snap at acute angles when they fall. Fillets assist by distributing the load and reducing maximum stress. That’s why tool handles or drone frames commonly leverage fillets.

Chamfers can protect edges from chips in handling, but in high-impact areas, they may not arrest cracks as effectively as fillets. Best practices suggest adding fillets to where parts face hard knocks, and chamfers to facilitate assembly or avoid nicks on less critical edges.

For brittle-material parts, a small fillet along impact-prone edges can be the difference between short and long service lives.

Beyond the Basics: Hybrid Edges to Prevent Warping and Reduce Failed Prints

Hybrid edges hybridize fillets and chamfers, introducing new power and utility to high-end manufacturing. It’s transforming the way teams address age-old challenges—such as tension, printability and wastage—by tailoring edges for practical demands. These edges are prime in spaces where performance, aesthetics, and price all count — robotics, consumer tech, or EV components.

With the proper method hybrid edges can demonstrate distinct advantages in component strength, aesthetics, and throughput.

Combining Features

As discussed here, combining fillets and chamfers in a single design helps disperse stress and break up sharp transitions. This renders 3D printed parts less crack prone. For instance, a part with round and sloped edges can withstand stress more efficiently than one with only one.

CAD tools now allow engineers to insert these features exactly where they’re required, at mating surfaces or wear zones for example. This adaptability allows crews to experiment with edge combinations that suit both the component’s purpose and the manufacturing process.

In consumer tech housings, a hybrid edge can reduce visible layer lines and help the part look more finished. To do this well, designers need to set specific objectives—say minimizing material or increasing strength—and then apply CAD to position fillets and chamfers where they’ll have the most impact.

A hybrid edge at a battery casing, for example, balances impact resistance and a tight mechanical fit. The impact is clear: parts last longer, look better, and can be made faster. Hybrid edges waste less material, providing just enough support where it matters.

Variable Edges

At the extreme are variable edge treatments, which may change in size or type along a part, providing additional control over stress and appearance. In a lattice or honeycomb structure, a hybrid edge could be wide at one end for strength and narrow at another to save weight. This comes handy in aerospace and EVs, where every gram matters.

Industries are leveraging these adaptive edges today to make stronger, lighter parts without increasing cost. 3D printing teams, for instance, can prevent warping by adjusting edge geometries as the model expands.

This implies that there is lesser likelihood of cracking, resulting in lesser failed prints. Designers should really experiment with variable edges. Understanding a material’s boundaries and aligning edge style to stress locations results in pieces that print more simply and endure longer.

Design for Assembly (DFA): How Do Edge Treatments Play a Role?

DFA comes from the world of manufacturing, where the goal is to make parts simple to fit together, reduce errors, and accelerate assembly. Edge treatments—primarily fillets and chamfers—do a lot of this. Good edge design translates into fewer mistakes, cheaper cost, and slicker assembly lines. Badly arranged edges can jam things up or cause defects.

Selecting your edge style early in your design keeps things humming along and prevents surprises down the manufacturing road.

Guiding Parts

Chamfers tend to assist in guiding parts into place. They allow screws, pins or shafts to slide through holes without snagging, which is great when stuff’s gotta line up quick on a hectic line. Fillets, in contrast, smooth the transition between surfaces. This aids parts to slide or rotate into place and prevents sharp corners from catching.

For instance, a chamfer on a mounting hole simplifies the manual threading of a bolt, while a fillet on a bracket’s edge allows it to nest a curved cavity with less effort. Edge treatments that guide parts can cut assembly time and the potential for cross-threading or jamming. Designers should always seek to add chamfers or fillets anywhere parts join or align, particularly if assembly is manual or tolerance is tight.

Reducing Interference

These edge treatments reduce friction between mating components. Chamfers are a favorite for holes and entry points since they funnel parts in, avoid binding, and assist with lining up parts even if the fit is less than perfect. Fillets assist as well, softening edges so components won’t actually bite into each other.

It’s imperative to think about tolerances and clearances—tight fits are more expensive to produce and increase the chances of assembly issues. If design for assembly techniques are applied, the total assembly time can be reduced to less than 1 minute. Smart use of edge treatments equals less tweaking, less rework, which equals time and money savings — and assemblies that perform better in the field.

Wear and Tear

Edge style impacts part life. Sharp corners not only wear out more quickly but can cause abrasion, particularly in moving assemblies. Fillets distribute force and minimize stress concentrators and therefore crack initiation.

For instance, the fillets on the high-load edges in robotics joints or EV mounting brackets prevent parts from wearing down or breaking. Chamfers can assist where edges meet moving parts, but fillets are generally safer and easier to deal with, particularly in consumer products. The correct decision here depends on the application of the part—fillets for safety and durability, chamfers for guiding and fit.

How Do You Choose the Right Edge Treatment Between a Fillet and a Chamfer?

This decision should be a performance-driven one, based on manufacturing limitations and product context. Use this point-form framework to guide your selection:

- Identify the fundamental role of the part and its context.

- Identify material type and manufacturing process limits.

- Weigh aesthetic goals and user experience.

- Calculate cost, time, and tool availability.

- Review assembly and maintenance needs.

- Document the rationale for future design cycles.

Designers have to consider how an edge will be used, how it will look, and how it will be constructed. Fillets and chamfers both have their benefits. Fillets soften hard edges, assist with stress reduction, and enhance safety.

Chamfers help with assembly and are great for mated parts or those that need easy alignment. Each technique alters the appearance and price, and affects the manufacturing process of a component.

Practical tips: assess the trade-offs by asking if safety or assembly is the main concern, look at the machining cost, and review what tools are available. Fillets often need a ball nose end mill, which adds cost and setup time.

Chamfers can be cut with a single tool, speeding up production. For holes and fasteners, chamfers prevent damage and make it easier to insert screws. Documenting your decisions and the reasoning behind them assists in making future projects better.

It facilitates design reviews and retains knowledge for teams. For complex projects, Wefab.ai offers an AI-first contract manufacturing service. It’s a one-stop platform for 3D print and beyond.

Using automated checks, the platform looks for risky edge features, flagging fillet or chamfer issues before they become expensive. AI-powered DFM analysis from Wefab.ai accelerate feedback, so you receive design tips that align with both function and manufacturability.

That translates into less surprises, less cost, and more quality, whether it’s for a robotics prototype or an EV battery case.

By Function

Edge selection is based on what the part has to accomplish. If the design has to defend users, fillets attenuate corners, decreasing the chance of harm. This is important in consumer tech or components that are frequently touched.

For interlocking parts—such as brackets or mounting plates—chamfers assist direct the fit and simplify assembly. In robotics, chamfered edges prevent parts from snagging as they move.

If a part deals with load, fillets reduce stress at sharp corners, making the part tougher and less prone to break. When the requirement is quickness in either putting things together or steering screws down holes, chamfers prevail for pragmatism.

By Material

Various materials respond to edge styles differently. Metals like fillets where stress is high – they prevent cracks from forming. Plastics, particularly injection-molded plastics, employ fillets to reduce warping and increase flow in the mold.

For brittle materials such as ceramics, chamfers help prevent chipping. Fillets are not always easy to make on hard or abrasive materials due to tool wear. Machining a fillet in stainless steel may require additional passes and tool changes, increasing cost.

Material selection influences tip shape, so verify what suits your design. Utilize fillets to increase strength in ductile metals. Use chamfers for when the material snags or flakes.

By Aesthetics

-

A rounded fillet provides that soft, modern vibe ubiquitous in consumer tech, while a chamfered edge implies precision and industrial design.

-

In climate tech, fillets on exposed components make equipment appear approachable, in tune with safety and sustainability-conscious brands.

-

In robotics or EV hardware, sharp chamfers create a bold, technical style that appeals to professionals and screams performance.

-

For luxury products, filleted edges imply high craftsmanship. For tough equipment, chamfers prove durable.

Match edge style to your brand image and the user you want to serve. Select fillets for warmth and friendliness, chamfers for crispness and precision. Great design is both aesthetically pleasing and useful.

By Print Process

3D printing rewrites the rules for edge treatments. FDM printers love chamfers, too, because straight edges print super cleanly, and support removal is easier. While SLA or SLS printing can do tight fillets, too small a radius can create weak spots or print defects.

Print settings are important. Fillets and chamfers come out smooth or rough depending on layer height and print orientation. For thick parts, a big fillet is simple to print. For fine details, sharp chamfers can be tricky, therefore designers should check out the printer’s boundaries.

Be sure to confirm your print method before design final edges. AI-powered checks from platforms like Wefab.ai identify risky characteristics upfront, so the ideal edge style can be selected prior to production.

Need Expert Guidance on Fillet and Chamfer Selection?

Partner with Wefab.ai’s specialists, providing AI-driven analysis and design optimization for EV and consumer hardware components.

Connect with Wefab.ai Experts to Elevate Your Designs!

Conclusion

Design teams in industries such as climate tech, robotics, electric vehicles (EVs), and consumer hardware often face critical decisions regarding edge treatments, which significantly influence both production costs and timelines. Fillets, with their curved transitions, effectively reduce stress concentrations and enhance load-bearing capacity, while chamfers, featuring angled edges, facilitate precise fits and improve handling efficiency. These choices not only affect print duration and part strength but also play a pivotal role in determining overall quality, cost-efficiency, and time-to-market for innovative technologies. Thoughtfully integrating fillets and chamfers allows designers to optimize both the aesthetic appeal and functional performance of 3D-printed components, ensuring robust, safe, and expedient production outcomes.

Such strategic edge design decisions can mitigate delays, enhance product reliability, and align with stringent project schedules. To maintain a competitive edge in this demanding field, teams benefit from leveraging advanced tools and partnering with experts who understand these nuanced trade-offs. Wefab.ai offers comprehensive support and expertise, providing tailored 3D printing solutions to elevate your design process. Ready to enhance your edge treatment strategy? Explore Wefab.ai’s advanced 3D printing services to optimize your projects and drive success.