Acrylic sheets for laser cutting are our standard for clean edges, tight tolerances and stable yields in your prototyping and small-batch runs. Procurement teams encounter spasmodic lead times and resin price swings that drive unit costs upward and stall pilot builds.

Engineers fight melt, haze and micro-cracks when power density, focus height or sheet grade don’t align to cut path, which drives scrap rates and bogs down QA. Startups and mid-sized firms experience wide variability in sheet flatness, protective film quality, and thickness tolerance (±0.2–0.5 mm), impacting fit, bonding and downstream finishing.

To cut waste and risk, the next sections map material grades, optical and thermal specs, and AI-driven process controls that solve these challenges with repeatable results.

Understanding Acrylic Manufacturing

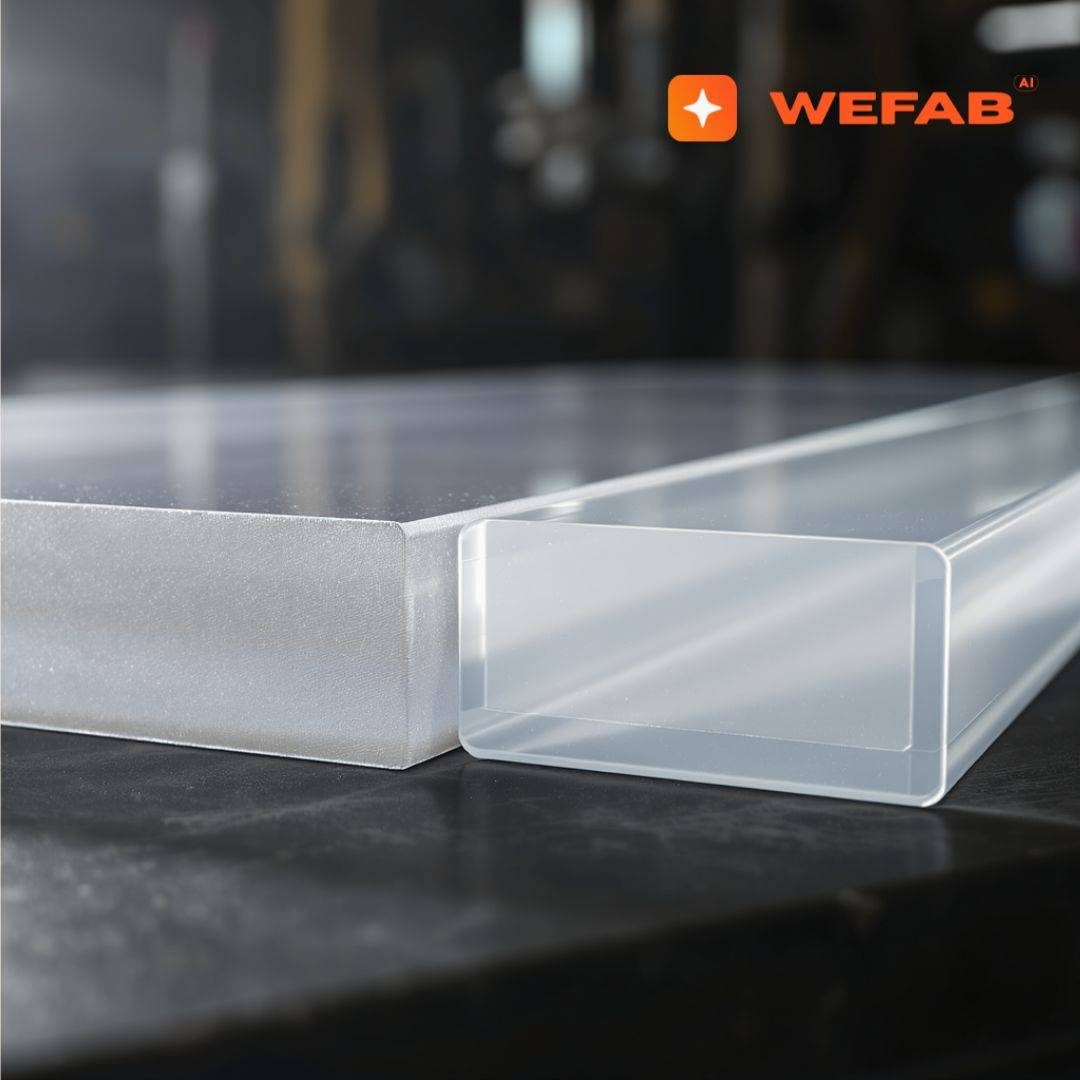

Acrylic sheet supply depends on the way the stuff is manufactured. Cast and extruded routes benefit from very different thermal and flow histories, which determine clarity, stress profile, thickness control and laser response.

Picking the right type minimizes scrap, accelerates machining, and elevates finish quality for your high-mix program.

The Casting Process

Cast acrylic begins as liquid methyl methacrylate monomer and initiators, poured between glass or metal molds, then polymerized at controlled heat, usually 150°C–230°C to avoid thermal degradation.

This slow cure produces a dense, low-stress matrix with optical transmission to 92%, meaning laser-cut edges are crisp and engraves are high-contrast. It machines well and doesn’t craze with fine engraving.

For laser cutting, cast grades exhibit pristine, glossy cut edges and deeper, more even frosts. Thickness tolerance is wider than extrusion because of batch mold variation, so sheets can drift by multiple tenths of a millimeter.

The payoff is a high-end surface and enhanced optical performance, handy for customer-facing components.

Common applications:

-

- Branded signage and architectural lettering.

- Show windows and museum cases.

- Decorative panels, light diffusers.

- Control panels and instrument panels.

The Extrusion Process

Extruded acrylic is made by melting acrylic pellets and blending color and viscosity in an extruder with twin rotating screws until a melt is produced.

This melt is then processed through a die and calender rolls, converting it into a uniform gauge sheet. Processing temperatures range from approximately 150°C to 230°C, maintaining stringent thermal control to prevent yellowing and warpage.

This path provides reliable thickness and reduced pricing, supporting panel yield in huge nesting jobs. Internal orientation and residual stress can be greater, and that can manifest as striations or micro-crazing around engraved areas.

Power, speed, and air assist require tuning – test on scrap to lock in settings before scaling up. Sheet up to around 20 mm, multiple passes or slower speed generally smooth edge quality.

|

Typical use cases |

Advantages |

Characteristics |

|---|---|---|

|

Retail fixtures, guards |

Lower price per m² |

Tight gauge control |

|

High-volume letters |

High yield in nesting |

Good clarity, not premium |

|

Covers, trays |

Fast availability |

Higher internal stress |

Choosing Your Acrylic for Laser Cutting

Pair acrylic style with your desired result. Establish finish, detail, thickness, durability and budget up front and then check against machine constraints and material information.

Cast and extruded act differently due to their manufacturing process, which impacts edge quality, engraving contrast, and thickness precision. Thinner sheets (3–6 mm) carve cleaner on most CO2 lasers, and knowing your material is half the battle.

Checklist:

- Edge finish: glossy, flame-polished vs. functional cut

- Engraving detail: contrast, depth, legibility at small features

- Thickness: tolerance, flatness, and machine focus window

- Budget: price per m², yield, scrap rate

- Durability: UV, chemicals, handling, expected life

Check out specs here for cast, extruded, matte frosted and fluorescent acrylic. Check haze, UV stability, thickness tolerance and if it’s rated “laserable.” Run a small test to lock settings & keep your burn marks away.

1. Edge Finish

For shiny, polished edges right off the laser, cast acrylic is the best, frequently displaying water-clear edges as a result of clean melt and resolidification.

If sanding/painting or hiding in an assembly you’re doing to the edges, extruded acrylic is great and cost saving. Edge smoothness differs for each laser parameter.

On 3 mm acrylic for example, a good place to start is 80% power at 8 mm/s, this often produces flame-polished edges on many CO2 rigs. Test sample cuts of both types, look for striations, whitening and micro-chips under light.

2. Engraving Detail

Opt for cast acrylic for crisp, high-contrast engraving on logos, scales and QR codes. Extruded can appear dulled by internal stresses and flow lines.

Adjust power, speed and focus. Try on scrap and get just deep enough to not cloud. For frosted/matte, use lower power to preserve surface.

3. Thickness Tolerance

Choose extruded if you require uniform thickness throughout a large batch of parts, for example press-fit tabs or layered jigs.

Cast is a little variable, account for that in slot widths. Calipers before cutting and focus to actual thickness. For interlocking parts, add clearance equal to sheet tolerance.

4. Project Budget

Extruded is the standard for cost-led work or large quantities. Go cast when the quick calls for classy edges and engraving.

Compare price/sq meter with anticipated yield and scrap rate. Superior cut quality minimizes rework and overall cost.

5. Material Durability

Cast acrylic has clarity with low haze (<1%), improved chemical resistance and weathering stability. Extruded has 1–2% haze with slight color drift, making it good for indoor or short-life parts.

Compare UV exposure, temperature swings, and handling loads. The majority of CO2 lasers cut as much as 12 mm dependably, while thicker stock may require industrial power.

Need a Perfect Laser-Cut Acrylic Part Without the Guesswork?

Whether you need the pristine, flame-polished edges of cast acrylic or the cost-effective consistency of extruded, we’ve got you covered. Our platform analyzes your design and instantly quotes the right material with optimized settings for a flawless finish every time.

Get a Perfect Cut with the Right Acrylic, Guaranteed.

Ideal Cast Acrylic Applications

Cast acrylic sheets are ideal for laser workflows, offering optical clarity and sharp engraving contrast, making them a premium choice for personalized signage and artistic projects. With low haze (<1%), they ensure pristine transparency for safety partitions and luxury displays, while their excellent machining properties minimize melting during extended cuts.

Intricate Jewelry

Cast acrylic results in crisp micro-features and clean edges, so filigree earrings, lattice pendants, and geometric charms cut consistently without burrs. Use 3mm sheets as a guide: 80% at 8mm/s is a nice baseline, dial down power for hairline details to save bridges and tabs.

Engraving yields a frosty white, high-contrast custom mark for monograms, logos and serials that remain readable at small sizes. That aids brand control and anti-counterfeit cues.

Color and finish options—opaque, translucent, fluorescent, mirror-backed—allow teams to craft SKUs across seasonal drops without retooling. The cast structure resists chipping in tight radii, maintaining fragile cuts robust through assembly and wear.

Bespoke Signage

Cast acrylic lends itself to crisp, high-contrast engravings and vibrant inlays for wayfinding, ADA-adjacent, and brand identity signage. Adequate for indoor lobbies and outdoor façades, its UV stability and weather resistance have minimal yellowing under lighting.

Routed or laser-polished edges appear glass-like. For lit signs, more light gets through for better halo and edge-lit effects, handy in retail roll-outs and transport hubs.

Define thickness by span and mount. For 6.3 mm (1/4 in), 50–60 W power and slower passes prevents micro-crazing on dense strokes.

Display Cases

For cases and covers, low haze and scratch resistance maintain goods & artifacts in the spotlight at different angles and LED hotspots. Retail, museum and exhibition teams prefer cast acrylic as it minimizes maintenance without compromising presentation value.

Rigidity keeps panels flat over larger spans. It stands up in public spaces as safety partitions, functional and with clean aesthetics.

Dial power and air assist to eliminate plume deposits on inside faces. Thicker panels require staged passes with focus offsets.

Artistic Pieces

Artists utilize cast acrylic for sculptures, wall art, and installations where tight kerfs and precise engravings matter. Stacked, multi-colored layers bring depth, parallax, and position-shifting light piping to the design.

Machinability enables intricate joints, heat-bent shapes, and CNC + polish hybrid processes. The inherent high-gloss finish reads as glass, elevating perceived worth in galleries and high-end interiors.

Ideal Extruded Acrylic Applications

Turn to extruded acrylic when cost control, consistent thickness, and fast turns trump top-notch optics. This premium quality material is great in standard sizes and volumes, enabling quick iteration and laser engraving beautifully on 30–100 W CO2 lasers, particularly at 3.1–6.3 mm thick with air assist for the removal of debris and minimization of fire risk.

Simple Enclosures

For protective covers, utility housings and straight-wall boxes, extruded sheet maintains geometry true and fit consistent. Thickness uniformity makes it easier to design press-fit tabs, hinge pins and gasket grooves, minimizing rework on assembly lines.

Where edge polish or deep clarity is less important, the cheaper material cost optimizes the unit economics. Standard 1,000 × 600 or 1,220 × 2,440 mm sheets provide nesting efficiency for small electronics enclosures, storage bins and machine guards.

CO2 laser cutting yields clean edges on 3.1–6.3 mm stock; thicker gauges are feasible but may require multiple passes or more wattage. Available in matte Frosted or fluorescent variants can provide rapid visual coding for work cells, trays or safety covers without post-process paint.

This helps spare-part programs and 5S color-tagging — on a budget.

Functional Prototypes

Opt for extruded acrylic for test rigs, brackets and jigs where you anticipate iteration. The price point allows several spins each day as you fine-tune hole patterns, dial tolerances or adjust cable paths.

Consistent thickness enhances stack-up precision in mechanical assemblies and minimizes shim usage. Prototype light-duty gears, light guides, or sensor windows before transitioning to cast PMMA, PC, or metal.

A lot of teams will try 50–80 W CO2 settings for 4–6 mm sheets to achieve clean features quickly. Air assist keeps kerfs crisp and the shop safe. Extruded colors and textures are ideal when high clarity is not required.

Use fluorescent edges for visual flow checks on conveyors, or frosted panels to mute glare on HMI bezels.

Layered Designs

Stacked thickness tolerance Architectural models, multi-level signage and user interface panels get consistent stand-off heights, which enhances alignment and keeps glue lines straight. Dimensional stability minimizes scrap during alignment, and matte or fluorescent coatings can add contrast in wayfinding or retail displays.

The reflective surface is perfect for signage, art panels, and fixtures where color pops.

- Map layer order with a simple exploded sketch

- Assign colors/finishes to each layer for contrast

- Note adhesive type, bond area, and vent paths

- Holes slotted for thermal relief and wire pass-through

- Define laser power per layer thickness (30–100 W)

- Add registration pins for repeatable assembly

- Validate air-assist settings and kerf offsets

The Hidden Factor: Material Stress

Internal stress in acrylic is a silent expensive factor. It manifests as warp during cutting, micro-cracks along sharp corners, poor edge finish, or fit issues in press-fit assemblies. Stress from polymerization, cooling rates, storage, machining history.

In laser cutting, this stress accumulates at heat-affected zones, where abrupt thermal gradients generate crazing or edge chips. For high-mix, low-volume builds, the impact is real: lost panels, rework, and schedule slip.

Cast vs. Extruded: Stress Profile and Laser Behavior

|

Attribute |

Cast Acrylic (PMMA) |

Extruded Acrylic (PMMA) |

|---|---|---|

|

Typical internal stress |

Lower, more uniform |

Higher, directional (machine direction) |

|

Edge quality when cut |

Glossy, less melt smear |

More melt, risk of striations |

|

Dimensional stability |

Better in both axes |

Variable; anisotropy common |

|

Risk of crazing post-cut |

Lower if dry and clean |

Higher, especially near tight radii |

|

Cost and availability |

Higher cost, wider thickness range |

Lower cost, common in thin sheets (2–6 mm) |

Mitigation: Anneal, Dry, and Tune the Laser

Annealing relieves locked-in stress, and more than pays for itself on assemblies with solvent bonding or snap features. For 3–6 mm sheets, a workable cycle is 80–85°C soak for 2–3 hr then cool at 10°C/hr to room temp with parts flat and supported.

Drying at 70°C for 2–4 hours minimizes edge whitening on high-power cuts. On the laser, slow down and reduce power density to limit heat spikes: use two passes at lower power instead of one hot pass, raise nozzle standoff, and use nitrogen assist to cut melt recast.

Maintain minimum inside radius ≥ sheet thickness – sharp internal corners trap stress. Space parts so heat doesn’t stack; a 5–8 mm web between features is a safe start.

Inspection: Catch Stress Early and Close the Loop

Check edges with cross-polarized light to expose residual stress bands. Check for crazing after a brief isopropyl alcohol swab, and if it does, then transfer to cast stock or re-anneal.

Measure warp on a flat granite or glass plate – anything over 0.3 mm bow per 300 mm indicates pre-bake or alternate sheet stock. For bonded parts, run a 24-hour soak test at 40°C to flag delayed cracking.

When speed and yield matter, route critical jobs through Wefab.ai: our AI-driven DFM flags risky geometries, selects cast vs. Extruded per tolerance and bonding plan, and prescribes anneal cycles and laser recipes. Teams experience less rejects, quicker release, and cleaner audits.

Worried About Warping, Crazing, or Poor Edges on Your Acrylic Parts?

Our manufacturing experts can help you choose between cast and extruded acrylic and optimize your design for laser cutting to prevent defects, reduce costs, and ensure your parts fit and function perfectly.

Get a Free DFM Review for Your Acrylic Design.

Maximizing Your Laser Cutting Results

Acrylic is extremely responsive to laser engraving when you dial in settings for the specific polymer and thickness. Clean edges, tight tolerances, and repeatable quality depend on disciplined setup, quick validation, and stable process control.

- Calibrate your laser cutter for the specific acrylic type, thickness, and desired finish to achieve clean, precise cuts.

Begin with premium quality material grade. Cast acrylic gives crisp, flame-polished edges and engraves with a frosted appearance. Extruded acrylic cuts quicker but is more susceptible to melting and edge striations.

Use the 10 W per mm rule as a baseline: for 10 mm sheet, plan on a 100 W laser; for 3 mm, 30 W is a starting point. Then finish needs. For display-grade edges, favor slower speed with sufficient air assist to prevent micro-charring.

Run a test cut on scrap from the same lot to confirm kerf width, edge clarity, and heat-affected zone before you switch to production parts.

- Apply masking film to protect acrylic surfaces from smoke residue and scratches during the cutting process.

Keep the factory film on when feasible, or re-mask with laser-safe paper film. Clean sheets first with a microfiber cloth — dust and fingerprints can trap heat and leave blemishes.

Masking regulates surface temperature, minimizes soot deposition, and decreases post-processing. For small text or fine features, utilize low-tack film to avoid chip-out during peel.

- Optimize cutting speed, power, and focus settings based on material properties for best results.

Adjust one parameter at a time. Employ air assist to blow away vaporized acrylic, avoid flare-ups, and enhance edge crispness.

For example, 3 mm cast acrylic tends to cut well around 80% power at 8 mm/s with typical air assist and tight focus, yielding flame-polished edges. Increase speed for extruded sheets to minimize melt, or drop frequency (Hz) to minimize continuous heat input on sensitive geometries.

Test with a matrix of mini coupons. Document power, speed and frequency to lock in a recipe by thickness.

- Maintain a clean lens and proper ventilation to ensure consistent laser performance and safety.

A dirty lens diffuses energy — resulting in wider kerf, burn marks and uneven penetration. Check and clean optics prior to each shift.

Double check focus height with a gauge — even 0.2 mm drift will ruin your edge quality. Provide consistent air assist and good exhaust to remove fumes and reduce the chance of fire.

Stable ventilation minimizes smoke staining under the masking. Record settings, lens condition, lot numbers. This creates traceability and reduces debug time.

For production scale or multi-site runs, Wefab.ai can standardize DFM checks, run controlled test cuts, and capture recipes across vendors, improving transparency and speed while holding finish targets.

Conclusion

Acrylic selection determines forms, surface, and per piece price. Cast grades provide crisp edges and a tight fit. Extruded grades cut quick and retain value. Warping of small parts due to stress in sheet slows downstream work. Inferior stock contributes haze, micro-cracks and scrap. Long setup cycles drive lead time and labor spikes. Teams feel the hit through late builds, rework, and missed specs.

New, AI-led sourcing and process control lift line flow and quality Clean data drives sheet selection by thickness, batch, and color. Stable feeds and optimized optics minimize heat damage and burr. Parts come in tolerance and go straight to assembly. Purchasing obtains cost visibility and consistent access.

Frequently Asked Questions

Which acrylic type is best for laser cutting: cast or extruded?

For your next project, cast acrylic sheets offer excellent machining properties with a frosty finish that is ideal for crisp laser engraving. While extruded acrylic may be suitable for high-volume needs, cast acrylic remains the premium choice for tight tolerances and striking contrast.

How does acrylic manufacturing affect cut quality and accuracy?

Cast acrylic sheets offer uniform stiffness and lower internal stress, making them an excellent choice for projects requiring consistent kerf and sharp details. In contrast, extruded acrylic can vary by batch in edge clarity and fit.

What thicknesses of acrylic are ideal for laser cutting?

Typical laser-friendly thicknesses for premium quality projects are in the 1.5–10 mm range. For thin features, it’s best to remain in the range of 2–5 mm. Anything above 10 mm necessitates slower passes and more power, increasing heat-affected zones. Wefab.ai checks thickness versus design features pre-production for optimal results.

When should I choose cast acrylic over extruded for applications?

Use premium cast acrylic sheets for signage, light guides, and precise jigs where edge quality and laser engraving contrast matter. Select extruded acrylic for covers, blanks, and high-volume components where speed and price are crucial, ensuring the material matches optical clarity, fit, and budget.

How does internal stress in acrylic impact laser cutting results?

Residual stress in materials like cast acrylic sheets can lead to warping, crazing, or micro-cracks post-cutting or solvent bonding. Cast acrylic typically exhibits lower stress compared to extruded types. Controlled annealing at 70–80C, available through Wefab.ai, can mitigate these failures.

What settings improve edge quality and minimize melting?

For your next project, employ good focus and air assist while utilizing several faster passes instead of one slow one. This method, along with maintaining clean optics, will ensure premium quality results for your designs with cast acrylic sheets.

Are there design guidelines for kerf, spacing, and holes?

Factor in 0.1–0.2 mm kerf per cut when working with premium quality acrylic sheets. Keep slot widths ≥ material thickness, and ensure hole diameters ≥ material thickness for strength in your next project. Wefab.ai performs design-for-manufacturing checks prior to cutting.

What post-processing improves performance and appearance?

Flame polishing enhances optical clarity on cast acrylic sheets but may induce stress. Vapor polishing, on the other hand, is softer for edges, making it an excellent choice for artistic projects. Deburr with fine grit, and don’t be heavy with solvents for the best results.