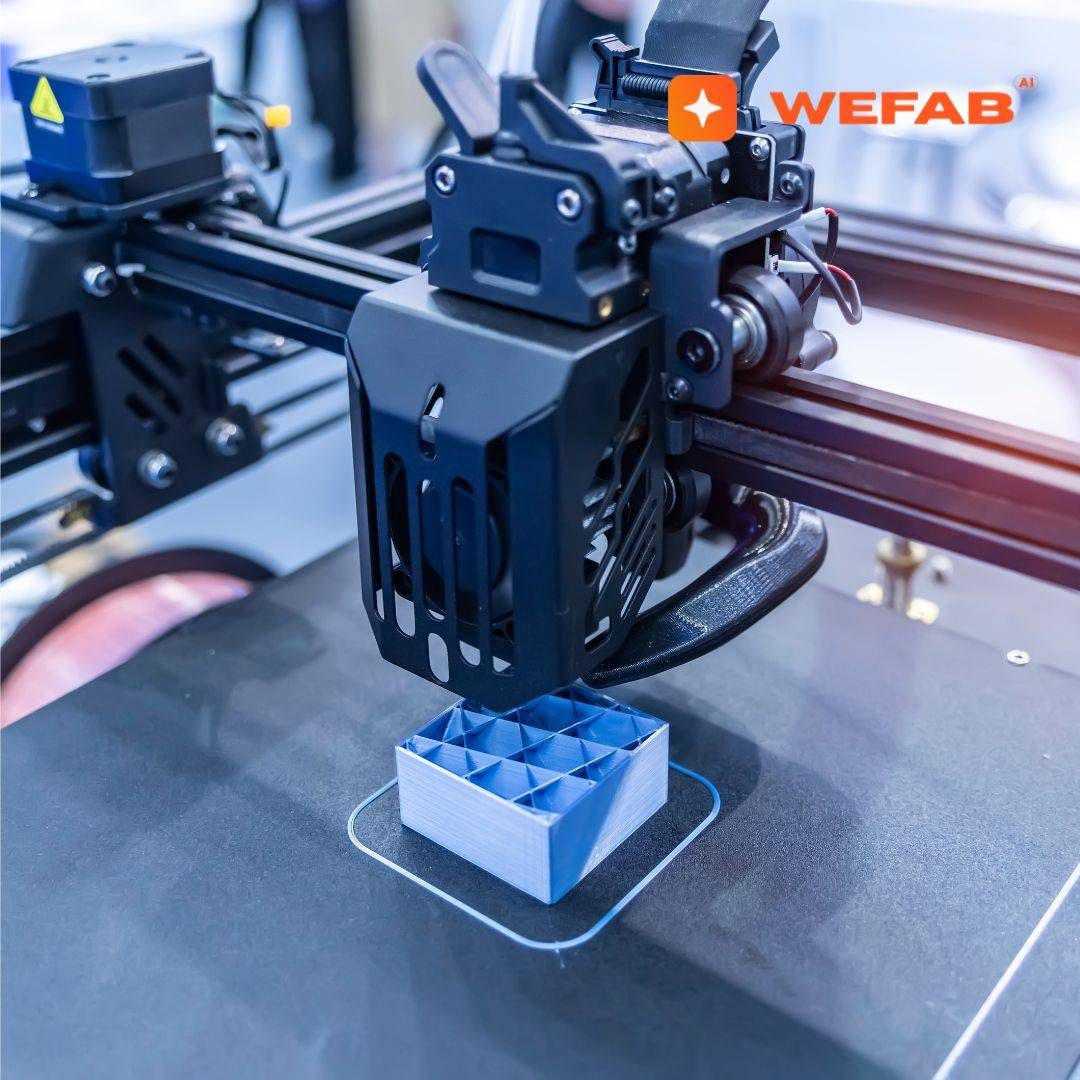

Resin 3D printing employs a liquid photopolymer resin, curing it one layer at a time with light to produce detailed components. This process distinguishes itself by its high resolution, superior surface finish and capability to produce intricate geometries not possible with other 3D printing technologies.

From climate tech to robotics to consumer electronics, manufacturers use resin 3D printing to build prototypes and end-use parts because it offers precision repeatable results. Resin printers enable teams to reduce lead times, reduce costs and accelerate design cycles.

For companies requiring small runs or detailed components, resin 3D printing unlocks more possibilities than traditional techniques. The following section will discuss essential advantages, workflows, and practical applications.

What is Resin 3D Printing?

Resin 3D printing, known as stereolithography or SLA printing, is a type of additive manufacturing where objects are formed by curing liquid photopolymer resins layer by layer. Each layer is UV cured enabling the production of incredibly precise, detailed parts.

Unlike machining or other subtractive methods, resin 3D printing enables rapid prototyping and one-off parts where fine detail is critical — down to 10-micron layers. This allows you to create highly detailed models, dental devices, and functional prototypes featuring surface finish and complexity difficult to obtain with other methods.

Automotive, consumer tech and more have embraced resin 3D printing to accelerate design cycles, boost product transparency and set new standards for quality.

1. The Core Process

Resin 3D printing begins on the computer, slicing your digital model into thin layers. The printer applies a razor-thin layer of liquid photopolymer to a build plate.

UV light selectively cures this layer, hardening the shape. When one layer cures, the build plate moves and it repeats until the part is complete. Layer thickness, which can be as low as 10 microns, is a key factor in final detail.

Excellent quality requires precise layer curing, and even slight inconsistencies can cause defects. The build plate holds up the part as it forms, assisting with precision printing. Handling resin is crucial—light or air can ruin it, poor storage can lead to print failures.

2. SLA Technology

Stereolithography (SLA) employs a UV laser that traces and cures each layer in the resin vat. This laser-based method provides great accuracy and glossy surfaces, making SLA the go-to for prototyping and miniatures.

SLA printers utilize various resins such as standard, tough, and specialty blends for engineering or temperature resistance.

3. DLP Technology

Digital Light Processing (DLP) shoots entire layers of light at once, curing all points at once, rather than by points like SLA does. DLP is swift, making it great for bigger batch runs or just plain speed.

It provides fantastic resolution — backing fine details for jewelry, dental, and small component manufacturing.

4. LCD Technology

LCD-based printers utilize a backlit LCD screen to selectively mask UV light, solidifying the resin in layers. LCD printers are cheaper and more available to small businesses.

Monochrome screens allow for quicker curing, greater screen lifetimes, and less downtime. LCD-friendly resins provide strong elasticity and precision, ideal for practical prototypes and end-use items.

5. Photopolymers

Photopolymers are plastics embedded with photoinitiators that respond to UV light. They’re available in rigid, flexible, or specialty blends.

Choosing the appropriate resin affects durability, pliability, and aesthetics. Additives can boost properties, but strength still often falls behind FDM or SLS prints.

Photopolymer selection defines the purpose and longevity of the final part.

What Is the Difference Between Resin 3D Printing and Filament 3D Printing?

Resin and filament printing each have their place in contemporary additive manufacturing. Resin printing, commonly known as stereolithography (SLA) or digital light processing (DLP), utilizes liquid photopolymers cured by light. In contrast, filament printing, or fused deposition modeling (FDM), involves thermoplastic filaments extruded through a heated nozzle.

The following table outlines their core differences:

|

Feature |

Resin Printing (SLA/DLP) |

Filament Printing (FDM) |

|---|---|---|

|

Detail Resolution |

25–50 microns layer thickness |

0.4 mm nozzle, visible lines |

|

Surface Finish |

Smooth, limited to no finishing |

Layered, requires sanding |

|

Build Speed |

Slower (layer curing) |

Faster (large parts) |

|

Application Fit |

High-detail prototypes, art |

Functional, structural parts |

Detail Resolution

Resin printers absolutely crush filament printers in fine detail. With layer thickness as low as 25 microns, resin machines can duplicate geometries and sharp features that are important in high-precision prototypes.

FDM, in contrast, is constrained by nozzle diameter—typically 0.4 mm—which restricts detail and often leaves visible layer lines. These distinctions are stark in applications such as miniatures, dental models, and jewelry where every curve counts.

The technology’s capacity to produce fine textures or small mechanical parts is frequently what separates functional prototypes from unusable designs. Projects needing tight dimensional tolerances or crispy engraving will benefit the most from resin’s accuracy.

Surface Finish

With resin printing, you get significantly smoother surfaces than the filament methods. The cured photopolymer layers mix together more cohesively, frequently removing the grainy, stair-stepped surface associated with FDM prints.

This slickness is prized in consumer tech, art, and display models where style is everything. Some sanding or polishing is still sometimes necessary, but much less so.

Smoother finishes don’t just look nicer, they can reduce friction in moving parts and increase the comfort of wearables.

Material Properties

|

Resin Type |

Key Characteristics |

Typical Applications |

|---|---|---|

|

Standard |

Rigid, smooth, moderate strength |

Prototypes, models, figurines |

|

Tough |

High impact resistance, flexible |

Functional prototypes, snap-fit parts |

|

Dental/Biocompatible |

Certified for medical/dental use |

Surgical guides, dental aligners |

|

High-Temp |

Withstands elevated temperatures |

Molds, aerospace, automotive |

|

Castable |

Burns out cleanly, low ash |

Jewelry, investment casting |

Resin selection influences component function. Standard resins suffice for visual models. Tough resins fit load-bearing components.

Dental resins are medical standard, so they’re safe. High-temp varieties serve industries requiring heat resistance. Specialty resins open up advanced-use cases and carry higher costs.

Build Speed

FDM printers will frequently run larger jobs quicker than resin printers simply because of higher deposition rates. Resin print speed is based on layer curing time and exposure, which can slow work, particularly for tall pieces.

When it comes to small, detailed batches, resin printers win by curing entire layers all at once. Rapid prototyping of dental aligners or custom connectors utilizes this batch efficiency.

Faster turnaround means design cycles shorten, reducing time to market.

Post-Processing

-

Remove prints from build plate carefully to avoid defects.

-

Wash prints in isopropyl alcohol to remove uncured resin.

-

Cure using UV light for full material strength.

-

Sand or polish for smoother finish, if required.

-

Dispose of waste resin and cleaning solvents responsibly.

Strafing post-processing imperils weak or tacky parts. Devices such as ultrasonic cleaners or wash-and-cure stations assist in accelerating the preliminary processes.

If you want to reduce post-processing time, fine-tune exposure settings and use support structures carefully — don’t compromise quality for speed.

When to Choose Resin for Prototypes?

Resin 3D printing is a natural match for prototypes when fine detail, surface finish, and geometric complexity are important. It provides an easy method of bridging chasms between design and production with reproducible, quality outcomes.

Resin is a powerful option for teams requiring to impress stakeholders with true-to-life models, or test assemblies in real-world environments.

Unmatched Precision

Precision in resin printing also translates to closer fits, reduced assembly mishaps, and reduced risk of field failures. Small errors can cause catastrophic failures — especially for mechanical components such as gears or snap-fits.

In engineering, precise dimensions are key when testing actual function or gearing up for bigger production runs. Say, for instance, a robotics joint with tight tolerances requires a prototype that is true to the digital model, right down to the millimeter.

Resin printing provides that consistency.

Functional Testing

Resin prototypes are great for functional testing as they replicate the final product’s shape and, sometimes, its functionality. This is critical when fit, assembly or motion need to be verified prior to investing in expensive tooling.

Because resin printing is fast — particularly with DLP systems — teams can test, tweak, and reprint in a matter of hours. This rapid feedback cycle is essential in areas such as climate tech or automotive, where a new sensor housing or mounting bracket needs to fit perfectly the first time.

Prototyping a wind tunnel part in resin, for instance, gives you a no-brainer before metal cutting begins.

Design Validation

Physical resin models help designers and engineers catch design flaws early. Physical prototypes make it easier for teams and stakeholders to visualize size, ergonomics, and assembly.

There’s nothing like seeing and holding the part to catch problems that were overlooked on screen, which means better products and fewer last minute design changes.

Consumer electronics and medical device firms use this process to optimize new devices and prevent expensive errors down the line.

Industry Applications

Resin printing is used in industries ranging from healthcare—hello, dental aligners and surgical models—to electric vehicles, where bespoke mounts or housings are required in a hurry.

Robotics companies use resin for test runs of grippers, sensors, and chassis components. Small-batch runs of consumer hardware can take advantage of resin’s capacity to churn out detailed, production-quality parts quickly.

With the need for fast, accurate, small-batch manufacturing on the rise, resin printing’s popularity continues to expand among startups and established companies alike.

Facing Delays with Complex Prototypes?

Boost precision with Wefab.ai’s resin 3D printing, offering detailed parts, reduced lead times, and smooth finishes for robotics and EV projects.

Partner with Wefab.ai Today to Streamline Your Prototyping!

What Do You Need to Know to Start Your First Resin 3D Print?

Resin 3D printing is popular for its ease of use and ability to create parts with exceptional detail and smooth finishes, often exceeding FDM in precision. For the resin 3D printer rookie, this well-ordered methodology prevents expensive blunders and keeps the experience safe and fruitful. This part demystifies the 3D printing process with step-by-step instructions, from gear selections and safety procedures to slicer configurations — all aimed at pros looking to disrupt while managing budgets and safeguarding the workspace.

Essential Equipment

Resin printing does take some setup — it requires a clean, stable workspace, preferably segregated from living areas, to contain fumes and spills. Having a dedicated space — even if it’s just a corner with a table and some storage — avoids cross-contamination and keeps dangerous materials contained.

For workflow efficiency, introduce a curing station and storage for your tools and consumables. Pick equipment prioritizing reliability, compatibility, and simplicity—checking manufacturer support and user reviews sidesteps frequent rookie blunders.

Workspace Safety

Resins emit fumes and irritate skin, so safety should never be optional. Be sure you’re wearing nitrile gloves and goggles so you don’t come into direct contact with uncured resin. Ventilation is a must; use the printer near an open window or with an exhaust fan to control fumes.

Maintain a clear workspace to reduce spills and make cleaning easy. Handle resin waste safely according to your local guidelines—never dump it down the drain. Instead, cure surplus resin under UV light prior to disposing in household trash and capture spent alcohol in a sealed container for proper disposal.

Slicer Settings

Slicer Software transforms 3D models into printable files, and it’s crucial to remember that not all slicers are created equal. The settings of your slicer significantly impact print quality, especially when using 3D printer resins. Key parameters like layer height (start with 50μm), exposure time, and lift speed are essential for achieving superior print quality.

It’s also vital to verify settings against your printer’s specifications, as each brand and model varies. Experimenting with slicer configurations and different types of resin—such as flexible or ABS-like—can improve durability and surface quality.

Take notes on what works best for different projects, and consult expert resources or Wefab.ai’s 3D printing services for personalized assistance.

How Does a Rigorous Post-Processing Workflow Help Teams Hit Production Targets?

Good post-processing transforms resin 3D prints from raw artifacts to functional, beautiful parts. All three steps, washing, curing, and support removal, directly contribute to the success and dependability of the printed part. Regular, rigorous workflows are required for teams seeking to hit production targets and reduce expensive mistakes.

Pioneering automation and AI-enabled oversight, as now evident in AI-powered contract manufacturing platforms, introduce quantifiable increases in speed, transparency, and quality. The following sections dissect the essential stages of post-processing, delivering actionable advice for buyers and fabricators looking to optimize their workflows and increase component quality.

Washing

Washing is your initial hands-on step post-print removal from the build platform. It strips the tacky, uncured resin from every surface. Most teams opt for IPA at 90% or above concentration for best results, while some prints are better suited to specialized resin wash solutions.

Small pieces can be cleaned in ultrasonic baths, larger ones can be agitated by hand in sealed bags or jars. Full washing is a must; leftover resin will leave blemishes and stickiness and will prevent curing. Post-wash parts have to dry entirely.

Compressed air or a lint-free towel aids in removing any trapped liquid, decreasing the chance of streaks or surface blemishes prior to curing.

Curing

Curing is the point at which prints attain their full strength. UV curing stations with controlled light and heat are preferred for consistency. Some users improvise with sunlight or handheld UV lamps, but these rarely guarantee even exposure, which can result in brittle or undercured spots.

It’s essential to adhere to resin manufacturer recommendations and/or recommended exposure times and energy levels in order to prevent warping or under-curing. Flipping prints while curing or using turntables provide the most even results.

Temperature control stops thin or fragile details from straining due to overheating — they’re susceptible to warping if hardened too rapidly.

Support Removal

Supports are essential for more complicated geometries, but they can be dangerous to remove. Once cured, supports harden and can snap, blemishing or causing stress marks. Tools like flush cutters, needle-nose pliers, or dedicated scrapers are commonly employed to facilitate extraction.

For complicated components, patience is rewarded — yanking it off tends to ruin the finish. Designing with minimal, easy-to-reach supports can save time downstream. Slicing software with digital tools assist in placing supports to minimize post-processing work.

High-end shops might employ heat guns to help loosen tenacious supports, but this requires skill to prevent print deformation.

Explore Wefab.ai for advanced resin 3D printing solutions, AI-powered process management, and post-processing support tailored to production at scale.

Need Expert Support for Resin 3D Printing?

Partner with Wefab.ai’s specialists, providing AI-driven insights, post-processing support, and material optimization for consumer hardware.

Engage with Wefab.ai Experts Today to Elevate Your Designs!

Conclusion

Resin 3D printing offers product teams in industries such as climate tech, robotics, electric vehicles (EVs), and consumer hardware a reliable solution for producing parts with exceptional detail, smooth surfaces, and enhanced durability, meeting the demand for precise and rapid prototyping. Unlike traditional methods, which often lead to project delays, missed specifications, or suboptimal finishes, resin printing minimizes waste and accelerates the design validation process by enabling the creation of intricate, robust components with complex geometries. This capability allows designers to closely approximate final product outcomes, streamlining testing and bringing concepts to life efficiently.

By optimizing material use and adhering to tight timelines, resin 3D printing delivers consistent value while maintaining cost-effectiveness across production runs. Wefab.ai enhances this process by providing expert support and advanced printing solutions tailored to your needs. Ready to elevate your prototyping capabilities? Explore Wefab.ai’s resin 3D printing services to unlock precision, efficiency, and success for your next project.