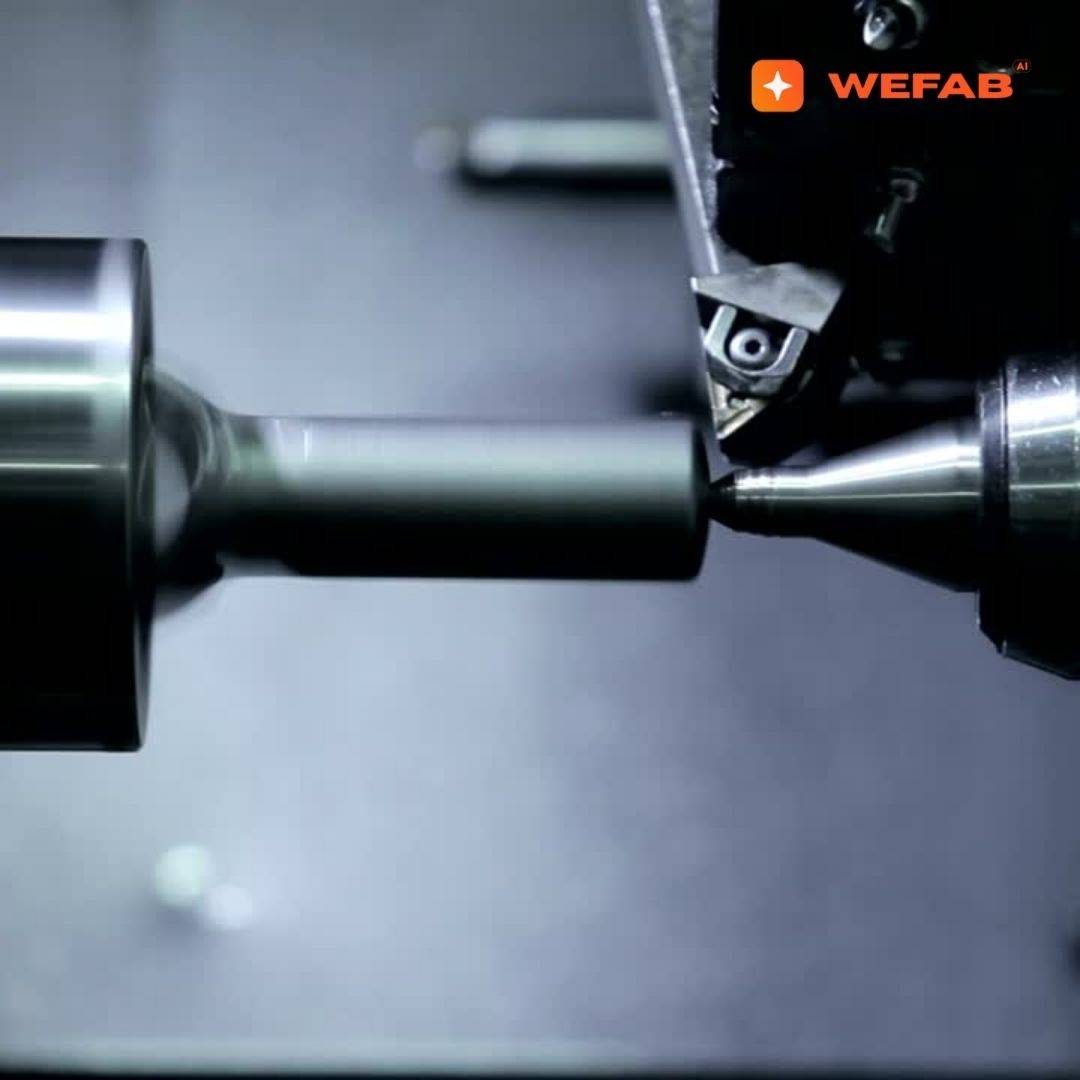

Precision CNC turning demands exacting tolerances on size and shape for every component machined on a computer-controlled lathe, where even a 0.01 mm deviation can disrupt the functionality of robotic assemblies, such as articulated arms or precision grippers. In the robotics industry, advanced CNC turning shops rely on sophisticated machinery and intelligent software to shape metals and composites into critical components with uncompromising accuracy. This precision ensures seamless integration of parts, enhances durability under dynamic loads, and minimizes failure rates in robotic systems. Manufacturers meticulously monitor tool wear, optimize cutting speeds (often exceeding 3000 RPM), and secure workpieces to maintain batch consistency, reducing scrap and preventing costly production delays.

However, tolerance issues—stemming from material inconsistencies or thermal expansion—persist, driving up costs and timelines in robotic component manufacturing. The integration of AI tools now offers a transformative solution, enabling early detection of deviations and rapid optimization of turning parameters. The following sections explore key strategies to address these challenges and maximize precision in CNC turning

What Are The Consequences Of Inconsistent Precision When Machining Robotic Joints And Drive Systems

Precision in CNC turning is at the heart of robotics — where a micron’s difference can cause misalignments, system faults, or expensive downtime. High precision machining is crucial in manufacturing components with intricate geometries and tight tolerances, such as robotic joints and drive systems. Inconsistent precision machining processes due to material differences, amorphous designs, or malfunctioning inspections necessitate transparency and clearly defined standards for teams across the world.

1. Design Ambiguity

It turns out that design ambiguity is the predominant source of manufacturing defects in precision machining processes. As we’ve already seen, slight misunderstandings with CAD models can be expensive when transitioning from pixel to part. Exact CAD drawings with specific tolerance zones are a must, but they must be met by transparent inter-team dialogue. Most teams, on the other hand, depend on design review meetings to identify potential misunderstandings early—a measure that can prevent subsequent rework and delays. For increased unmatched precision, developing a design checklist that highlights typical traps—such as ambiguous surface finishes, absent geometric dimensioning or undefined fits—assists groups in not making the same mistakes over and over.

2. Material Variance

Variance of material is an issue. Different metals and polymers machine in slightly different ways, resulting in different surface finishes and even final part sizes. Material batches can move tolerances by tenths of a millimeter, throwing off fit in assemblies. Dependable sourcing of material is necessary to reduce these dangers. Tryout for machinability, hardness and wear may show some surprises prior to production. Standardizing material specs across projects assists in keeping results consistent.

Shortcuts in material testing or sourcing can compound into bigger issues down the road.

3. Assembly Misfits

Bad fit between parts can grind a robotic assembly line to a halt. Tight tolerances in precision machining processes imply that even a small error can cause joints to stick or break. Test fitting during pre-assembly catches these issues, but design-assembly feedback loops are required to close the gap. Simulation tools now allow teams to preview assembly results prior to cutting any metal, which saves time and expense in cnc precision manufacturing.

|

Tolerance Level (mm) |

Risk of Misfit |

Impact on System Performance |

|---|---|---|

|

±0.01 |

Low |

Smooth operation |

|

±0.05 |

Medium |

Occasional jams, reduced accuracy |

|

±0.1 |

High |

Frequent faults, degraded control |

4. Performance Degradation

Small tolerance errors in the precision machining process accumulate over time, reducing the accuracy of robotic arms or end-effectors. Precision is connected to dependability—worn or out-of-spec components translate into increased failures. Routine inspections of component operation identify patterns prematurely, allowing engineers to repair prior to breakdown. Proactive fixes, such as periodic recalibration or component replacements, help maintain robots functioning correctly with unmatched precision.

How Do Issues Like Machine Complexity And Tool Wear Impact Production Costs And Scrap Rates: Operational Hurdles

Machine complexity, tool life, temperature shifts, and programming all stress production in cnc precision machining. These factors can erode tolerances, bog down runs, and increase costs, leading to lost time and higher scrap rates for hardware startups and supply chain managers, impacting overall output.

Machine Calibration

Calibration is what makes or breaks cnc precision machining on the shop floor. A lathe a fraction of a millimeter out of alignment can cause failed parts, wasted material, and returns. Regular calibration—timed to how frequently a machine is operated—maintains optimal precision margins and output quality. Calibration drift, if left unchecked, snowballs into bigger problems: small errors at setup mean larger errors in finished parts. Smart calibration tools, ubiquitous in modern CNC centers, accelerate the process and provide real-time feedback, making it easier to catch problems before they escalate.

Tool Wear

Tool wear gradually destroys cnc precision. As a carbide insert wears, surface finish deteriorates and dimensions bob out of spec. Close monitoring of tool conditions prevents unexpected breakage and waste. AI and sensor-driven predictive maintenance can detect early wear indicators before failure, ensuring high accuracy in machining operations. That keeps machines running longer, and it helps you schedule swaps during planned stops — not in the middle of a crucial run. Training operators to detect early warning signs—such as shifts in chip geometry or tool squeal—saves time and money.

Thermal Drift

Thermal drift occurs when machines or workpieces heat up and expand, displacing measurements by microns. For unmatched precision work, even slight temperature variations can disrupt accuracy. By employing temperature sensors, teams can monitor and modify conditions as necessary. Even better, fixtures constructed from stable materials reduce expansion. Maintaining the entire precision machining process at a constant temperature, in addition to designing for low heat generation, reduces the potential for drift.

Programming Nuances

Advanced multi-axis CNC turning programs can sneak in bugs. Optimized toolpaths = faster cycles + less tool wear. Higher-end software simulations allow programmers to try out code before it hits metal, ferreting out errors. Consistent education in new techniques assists squads in minimizing mistakes and keeping up with shifting machine capacities.

Wefab’s AI-driven solutions seek to transform these frequent stumbling blocks into opportunities for wiser, more resilient manufacturing.

How Do Tighter Tolerances Increase Machining Costs Cycle Times And Inspection Labor: Financial Impact of Tolerance

While accuracy in CNC turning is a primary contributor to quality, it significantly influences cost, lead time, and project success. Tolerance specifications inform all phases of the precision machining process, from machining to inspection, making it essential to align engineering demands with economic realities.

|

Tolerance Level |

Typical Range |

Cost Increase (%) |

Cycle Time (x) |

Inspection Cost (%) |

|

|---|---|---|---|---|---|

|

Standard |

±0.13 mm |

0 |

1 |

5–10 |

Baseline |

|

Tight |

±0.05 mm |

+15–30 |

2 |

15–25 |

Seen in electronics, aerospace, robotics |

|

Ultra-Tight |

±0.01 mm or less |

+200–2300 |

2–3 |

20–30 |

Rare, only for critical or moving parts |

Machining Costs

Tighter tolerances are expensive — tighter tolerances translate into longer cycle times, more tool changes, and slower cutting speeds which all increase the machining cost. For instance, going from standard (±0.13 mm) to tight (±0.05 mm) can add 15–30% to project costs, while ultra-tight tolerances drive costs as much as 24x higher. It’s not simply raw material or tool – operators need to change cutting bits frequently, contributing 20–30% to cutting time.

Every additional precision must be evaluated against its real advantage. Over-specifying tolerances, particularly on non-functional surfaces, can deplete budgets quickly—sometimes by 25–40% in prototype programs. Wefab’s AI-powered quoting utilities can assist teams in conducting cost-benefit checks, highlighting instances where standard tolerances are equally effective. Investigating advanced machining or hybrid techniques, like additive + subtractive, can reduce expenses while maintaining excellence.

Scrap Rates

Tolerance misses directly increase scrap rates, increasing total waste and material costs. Just off a little bit and you’re done, the whole batch is junk, especially if you’re working with tight specs. Scrap not only wastes material, it adds downstream costs to disposal, rework and late deliveries.

- Calibrated, routine in-process checks

- Automated feedback loops between machines and inspection

- Statistical process control (SPC) with AI-based alerts

- Early supplier engagement for tolerance review

Tracking scrap rates as a KPI encourages continuous process improvement and cost control.

Inspection Labor

Inspection labor is the secret expense in close-tolerance work. Manual checks on each part send labor costs soaring to 15–25% for tight tolerances vs standard 5–10% for standard parts. This matters when scaling output.

Automated metrology can reduce labor expenses and accelerate inspections. Experienced staff and regular training remain essential, as human oversight detects subtle errors systems could overlook. Optimized inspection flows, including batch inspection and risk-based sampling, reduce downtime.

Project Delays

Tolerance issues can drag projects, particularly if problems are identified late in the game. Delay is usually due to inspection or rework from missed tolerances. On-time checks are essential to intercept issues before they escalate.

-

Set tolerance goals early in design

-

Use digital twins to simulate tolerance effects

-

Schedule regular in-process checks

-

Build buffer time for rework

Project management software assist teams in tracking where tolerance risks exist and keep timelines on schedule.

Are Tool Wear Issues Disrupting Your Robotics CNC Turning Accuracy?

Enhance reliability with Wefab.ai’s AI-driven vibration control and monitoring to maintain ±0.005 mm precision in dynamic robotic components.

Contact us today to elevate your precision machining outcomes!

How Does AI Integration Lead To More Evidence-Based Manufacturing For Hardware Companies

AI is revolutionizing CNC precision machining by increasing the unmatched precision and traceability of every step in the precision machining process. Accurate CNC machining is no longer solely reliant on seasoned hands or premium machines — it’s about how tightly data, algorithms, and automation are integrated. For hardware makers, AI equates to less guessing and more evidence—each and every part, be it a prototype or a mega batch, receiving equal treatment.

Predictive Error Correction

AI can detect trends from previous machining data to anticipate trouble areas. Which means it can flag a probable mistake before it occurs—not after. Real-time adjustments can be made when it detects a tool becoming dull or a slight temperature variation. The machine can decelerate, accelerate or steer on the fly. So if it senses a minuscule vibration, for instance, the AI can alter the tool feed to avoid a poor cut.

Integrating these intelligent aids into today’s CNC configurations doesn’t require a complete revamp. Most shops install AI-powered software to current equipment. This is how the AI learns from what’s occurring and transmits feedback to machines and humans alike. Over time, both improve—operators learn what to look for, and the AI refines its abilities with every task.

Automated Quality Control

AI-powered quality systems eliminate a lot of human guesswork. Using computer vision, machines examine every piece as it leaves the line, detecting imperfections much more quickly than humans could. This keeps blunders from compounding. For example, a camera can detect a surface finish defect, even when it’s finer than the width of a hair.

Measuring these checks with quality metrics enables leaders to understand what works and what needs adjustment. Automated checks translate to lights-out manufacturing—factories can run overnight, with robots maintaining the same level of attention, 24/7. In the end, the entire process is less susceptible to drift or mistake.

Intelligent DFM Analysis

AI enables teams to detect design issues prior to production. It inspects CAD models for hard to cut shapes or tight tolerances. By catching these problems early, teams can modify designs to accommodate real-world machining constraints.

AI tools can even recommend adjustments, such as broadening a slot or adjusting a corner radius so components are simpler to manufacture. Even better, AI can attend design reviews, identifying dangerous features in real-time conversations. This keeps the entire project flowing with less bops.

How Does Wefab Customize Machine Parameters To Select The Optimal Vendor And Tool Paths

Wefab.ai is the AI-first custom and contract manufacturer specializing in cnc precision machining for hardware companies, ensuring precision, speed, and reliability. The platform combines proprietary AI with rigorous quality control and a transparent end-to-end process to tackle real-world supply chain and manufacturing challenges. AI-powered simulation customizes machine parameters and tool paths, selecting the optimal vendor for each task. This approach enhances efficiency while minimizing errors, downtime, and costs. For climate tech, robotics, EV, and consumer tech companies, this shift focuses on building scalable and sustainable products rather than firefighting defects and delays.

|

Aspect |

Traditional CNC Turning |

Wefab’s AI-Driven CNC Turning |

|---|---|---|

|

Efficiency |

Manual setup and adjustments |

AI-optimized settings and tool paths |

|

Accuracy |

Dependent on operator skill |

AI-driven precision and real-time QC |

|

Cost-Effectiveness |

Higher due to errors, downtime |

Lower via predictive maintenance, fewer defects |

|

Transparency |

Limited job tracking |

Proactive project updates via AI agent |

|

Vendor Matching |

Manual, often inconsistent |

AI-matched to best-fit capabilities |

|

Maintenance |

Reactive, after breakdowns |

Predictive, scheduled before failures |

Proactive Design Insights

Wefab’s AI-powered design for manufacturability (DFM) tools let engineers spot tolerance issues upfront, not after a run is done. That matters for robotics and EV companies where tight specs drive performance. By leveraging AI feedback in the design phase, teams sidestep last minute alterations. When design and AI engineers collaborate, that means fewer setbacks, improved yield, and reduced scrap.

“Early insights = fewer revisions + faster launch cycles”

Real-Time Monitoring

Preserving unmatched precision in machining depends on regular supervision. AI monitors each machine’s temperature, vibration, and noise patterns, snaring minor deviations before they escalate into failures. Dashboards allow managers to visualize job progress, highlighting anything astray. These real-time tools reduce guesswork and assist teams in resolving problems before they impact quality or schedule, ensuring high accuracy and consistent production.

Consistent Quality

With AI in quality control, less bad parts leave the floor, enhancing the cnc precision machining process. Sensor data powers analytics that detect trends in part dimensions or surface finish, leading to optimal precision. Over time, these insights help establish new standards for what ‘good’ looks like, making quality a habit, not luck.

What Are The Key Trends Shaping The Future Of Precision CNC Machining

Precision machining is undergoing a rapid evolution, particularly in CNC machining techniques, reshaping how industries approach the CNC turning process. The following key points outline the transformative trends driving this future.

- Integration of AI and IoT Smart factory systems, powered by AI and IoT, enable real-time monitoring, quantification, and resolution of issues, reducing scrap and boosting productivity. Digital twins—virtual replicas of physical machines—allow teams to identify imperfections before they impact progress, enhancing engineering precision and minimizing errors.

- Rise of Micromachining: The demand for micromachining, which produces tiny components with ultra-tight tolerances, is surging. This trend supports industries requiring intricate parts, such as medical devices, sensors, and consumer tech, driving innovation in precision manufacturing.

- Transformation of Traditional Workflows: AI revolutionizes conventional methods by automating part tracking, quality verification, and learning from each production run. This leads to faster setups, reduced errors, and improved collaboration between teams and suppliers, optimizing raw stock usage and cutting energy consumption.

- Shift to Sustainable Materials: The adoption of eco-friendly metals and plastics is gaining traction as regulations tighten and costs evolve. Companies embracing sustainable options not only reduce environmental impact but also achieve significant cost savings over time.

- Critical Role of Skilled Craftsmen: While AI and robotics enhance capabilities, expert machinists remain essential, guiding and refining processes. The synergy between human expertise and intelligent technologies delivers optimal results, underscoring the importance of ongoing training to keep teams competitive.

- Emphasis on Training and Adaptability: Investing in fast-learning teams is vital, enabling them to leverage AI and digital tools for troubleshooting and identifying new opportunities, ensuring adaptability in a dynamic industry landscape.

- Trend Toward Reshoring Production: Production is increasingly relocating closer to retail markets through reshoring, minimizing shipping risks and enabling faster responses to demand. This shift heightens the need for precise, versatile CNC turning facilities in diverse locations.

- Vision for a Smarter Future: Collectively, these advancements point to a future where CNC turning is faster, more efficient, and highly reliable. Staying ahead requires continuous innovation, blending cutting-edge technology, skilled workforces, and a commitment to sustainability.

Are Tolerance Deviations Stalling Your Robotic Joint Production?

Optimize precision with Wefab.ai’s AI tools to reduce scrap by up to 15% while enhancing dimensional accuracy for seamless robotic assemblies.

Request a custom quote today to transform your CNC turning process!

Conclusion

Precision in CNC turning serves as a critical foundation for the future of robotics hardware, where adherence to tight tolerances—often within ±0.005 mm—minimizes material waste and operational costs while ensuring component reliability. Even minor deviations can precipitate launch delays or erode user trust, particularly in robotic systems where precision is paramount for seamless articulation and load-bearing capacity. The advent of AI and advanced smart tools has revolutionized this landscape, enabling rapid identification of tolerance risks and maintaining alignment with exacting output specifications.

Platforms like Wefab.ai deliver these advancements to the shop floor, leveraging high-resolution sensor data to capture minute details during each turning pass and facilitating a streamlined transition from conceptual design to functional components with enhanced confidence. Transparent performance metrics provide actionable insights, quantifying how each parameter adjustment improves dimensional accuracy and reduces scrap rates by up to 15%. This evolution yields more robust robotic components, optimizes resource utilization, and sets a new benchmark for machining excellence.

Future innovations in smart machining will further elevate standards for speed and precision, empowering teams to meet the rigorous demands of robotics development. Ready to elevate your precision capabilities? Explore Wefab.ai and request an instant quote to tailor your CNC turning strategy.

Frequently Asked Questions

What Are the Primary Causes of Tolerance Issues in CNC Turning for Robotics?

Tolerance issues in CNC turning for robotics often arise from thermal expansion (e.g., up to 12 µm/m°C in steel alloys), tool wear exceeding 0.02 mm per hour, or inaccuracies in spindle alignment during high-speed operations (above 4000 RPM). These factors can lead to component mismatches in robotic assemblies, which may increase failure rates by 10-15% if unaddressed, highlighting the importance of precision machining techniques.

How Do Tight Tolerances Impact Robotic Component Reliability?

Tight tolerances, such as ±0.005 mm, enhance robotic component reliability by ensuring precise fits in articulated joints or sensor mounts, reducing vibration-induced wear by up to 20%. However, achieving such unmatched precision in the cnc precision machining process can strain production processes, risking higher rejection rates if material properties or machining conditions fluctuate.

What Role Does Thermal Management Play in CNC Turning Precision?

Effective thermal management is critical in the CNC turning process, as heat generation during machining can alter material dimensions by 0.01-0.03 mm due to thermal expansion. Poor cooling strategies during high-speed turning (e.g., 3000-5000 RPM) can compromise tolerance, necessitating advanced coolant systems to maintain optimal precision in robotic parts.

How Can AI Mitigate Vibration Challenges in CNC Turning for Robotics?

AI mitigates vibration challenges by analyzing real-time spindle data and adjusting cutting parameters—such as feed rates (e.g., 0.1-0.2 mm/rev)—to reduce amplitude by up to 30%. This enhances surface finish quality and precision machining processes, which are critical for robotic components operating under dynamic loads.

What Are the Cost Implications of Tolerance Deviations in Robotic CNC Turning?

Tolerance deviations can increase production costs by 15-25% due to scrap, rework, and delayed robotic system integrations. For instance, a 0.015 mm error in a gear shaft may require re-machining, adding $500-$1000 per batch, underscoring the need for optimal precision in CNC precision machining processes.

How Does Material Selection Influence CNC Turning Precision for Robotics?

Material selection significantly affects precision machining processes, with high-strength alloys like titanium exhibiting 5-10% greater thermal distortion than aluminum during the CNC turning process. By selecting materials with stable thermal properties and optimizing tool coatings, one can ensure optimal precision and reliability in robotic applications.

What Advances in AI Are Shaping the Future of CNC Turning Precision?

Advances in AI, such as predictive maintenance algorithms and digital twin simulations, are enhancing CNC precision machining by forecasting tool wear (e.g., 85% accuracy) and simulating precision machining processes before production. These innovations reduce setup times by 20% and improve tolerance consistency for robotic components.

How Can Robotics Manufacturers Optimize CNC Turning for Global Supply Chains?

Optimizing CNC turning for global supply chains involves standardizing tolerance protocols (±0.01 mm) across facilities, leveraging AI to synchronize production schedules, and mitigating customs delays with real-time quality tracking. This ensures consistent delivery of precision metal components, even across diverse manufacturing regions.