Tooling cost overruns for EV startups translate to spend on molds, dies and fixtures during early production that’s higher than planned in injection molding. Many new EV firms encounter these soaring costs as they make the transition from prototype to small-batch runs. High-mix, low-volume orders and evolving design specs frequently lead vendors to revise quotes, decelerate timelines, or request additional funds. Sourcing delays for custom parts or design changes at the last minute can add to the bill.

For the hardware teams, these tooling cost overruns impact cash flow and can slow go-to-market. AI-powered supply chain tools now assist in identifying tooling cost spikes early, reduce waste, and maintain tooling cost budgets. The next piece reveals explicit actionable tips for startups to keep tooling costs in check.

What Are The Main Reasons Tooling Costs Increase For EV Manufacturers

The journey from prototype to scaled production is fraught with variables that can transform anticipated budgets into unpredictable moving targets. Factors such as design volatility, quoting inaccuracies, supplier disconnects, material selection challenges, and unforeseen modifications collectively drive up tooling costs, posing significant hurdles for manufacturers, especially in the EV industry.

1. Design Volatility

Frequent design changes, driven by shifting consumer demands or competitive pressures, are a leading cause of escalating tooling costs. Each iteration—such as transitioning from one concept to multiple designs within months—requires new molds or tool adjustments, adding both expense and time. Without effective change management or a structured process for tracking alterations, costs snowball, pushing projects off budget and schedule as revisions accumulate.

2. Quoting Inaccuracies

Initial cost estimates based on incomplete specifications or rough guesses often lead to budget overruns. Hidden fees—such as rush shipping or specialized tool coatings—emerge late, inflating expenses when detailed breakdowns are absent. The lack of transparent, itemized quotes makes it easy to overlook the true scope of costs, leaving teams vulnerable to financial surprises.

3. Supplier Disconnects

Misaligned expectations between startups and suppliers, compounded by communication gaps, time zone differences, or unclear specifications, result in costly errors. These disconnects disrupt workflows, necessitating expensive corrections and delaying progress as teams struggle to align with vendor capabilities.

4. Material Selection

Choosing the wrong tooling materials, such as unsuitable steel or polymers, can lead to premature wear or failure to meet technical standards. This triggers frequent repairs, extended downtime, and increased expenses, as suboptimal selections undermine the durability and performance of tools.

5. Unforeseen Modifications

Last-minute production changes, often lacking contingency planning, can turn minor adjustments into major cost overruns. Without foresight or flexible design considerations, these unexpected shifts disrupt schedules and inflate tooling expenses significantly.

What Are The Hidden Costs Of Using Less Expensive Tooling For Injection Molding

Tooling decisions can make or break an EV startup’s budget and success. Less expensive tooling might shine initially, but the true cost emerges later — in rework, schedule setbacks, and eroded trust. Wefab’s AI-driven approach helps illuminate these risks clearly, transforming hidden costs into visible data for more informed decisions.

Why Cutting Tooling Costs Backfires

Cheap tooling typically translates into more breakdowns, quicker wear, and greater defect rates. These issues don’t only introduce additional downtime—they increase unit costs as every defective component must be repaired or replaced. For startups with tiny lots or bespoke pieces, this can immediately erode any initial savings. A 27% cost overrun on a $100,000 tooling budget tacks on $27,000 in surprise charges — a huge blow for lean teams. If projects begin with bad scope or underestimating, overruns can slash ROI by 50% or increase it by 100%, which makes getting additional funding in the future that much more difficult.

See the Real Numbers

A markdown table makes the long-term cost impact clear:

|

Upfront Cost (USD) |

Avg. Maintenance/Year (USD) |

Avg. Defect Rate (%) |

5-Year Total Cost (USD) |

|

|---|---|---|---|---|

|

High-Quality |

100,000 |

5,000 |

1 |

125,000 |

|

Low-Cost |

70,000 |

15,000 |

8 |

145,000 |

It’s about more than just the sticker price. Expensive rework and excessive failure rates from bargain-basement fixes increase costs more quickly than even the best teams anticipate. On certain global projects, scope creep and bad estimates have driven costs 500% and more, like in giant construction overruns.

Tally the Real Cost

Total cost of ownership counts every expense: setup, maintenance, fixes, downtime, and lost product. Scope creep causes these costs to spike in bursts, easily escaping detection until it’s too late. Almost every other project suffers from this, and it makes budgeting and scheduling hard.

Act with Data

Visit each tooling investment for long-term value, not just up-front savings. Leverage AI and real-time data to identify risks upfront and plug budget leaks. Get your vendor to communicate clearly and frequently – poor communication can double delays and increase costs by 20%. Scope creep can strike any project, so monitor its advance carefully.

How Does Vendor Inconsistency Impact Production Quality And Lead To Rework And Scrap

EV startups have a brutal tooling cost set of hurdles. These hurdles frequently make or break a project’s schedule, quality, and budget goals.

|

Operational Hurdle |

Production Impact |

|---|---|

|

Vendor inconsistency |

Quality drift, rework, scrap |

|

Poor project planning |

Delays, cost overruns, missed milestones |

|

Weak communication |

33% higher project failure risk, misalignment |

|

Lack of risk assessment |

Unplanned downtime, budget blowouts |

|

No contingency fund |

Inability to absorb shocks, timeline slippage |

|

Siloed data and visibility gaps |

Late issue detection, resource waste |

Coordinate Multiple Vendors

With tooling, startups frequently operate with multiple vendors, even in different countries. Each supplier might have their own standards, processes and lead times. This makes maintaining consistent quality and timeline difficult. If a die shop somewhere lags or provides out-of-spec molds, the entire project grinds to a halt. Transparent specifications and frequent gatekeeping are essential. A few teams leverage dashboards to monitor supplier performance, identifying problems before they cascade. Even the best tracking tools are worthless without strong relationships and open communication.

Track Progress and Quality

Good project management is more than just creating a Gantt chart. It’s about being aware of what’s going on at each stage, who owns it, and what’s on the line. Weekly review teams which update lists catch problems sooner. Using zero-based budgeting helps scrutinize every expense, eliminating bloat. Smart companies establish a contingency fund—typically 10–15% of total cost—to deal with surprises such as material hikes or failed molds. Daily stand-ups and transparent documentation keep everyone aligned, which matters because miscommunication alone accounts for a third of project failures.

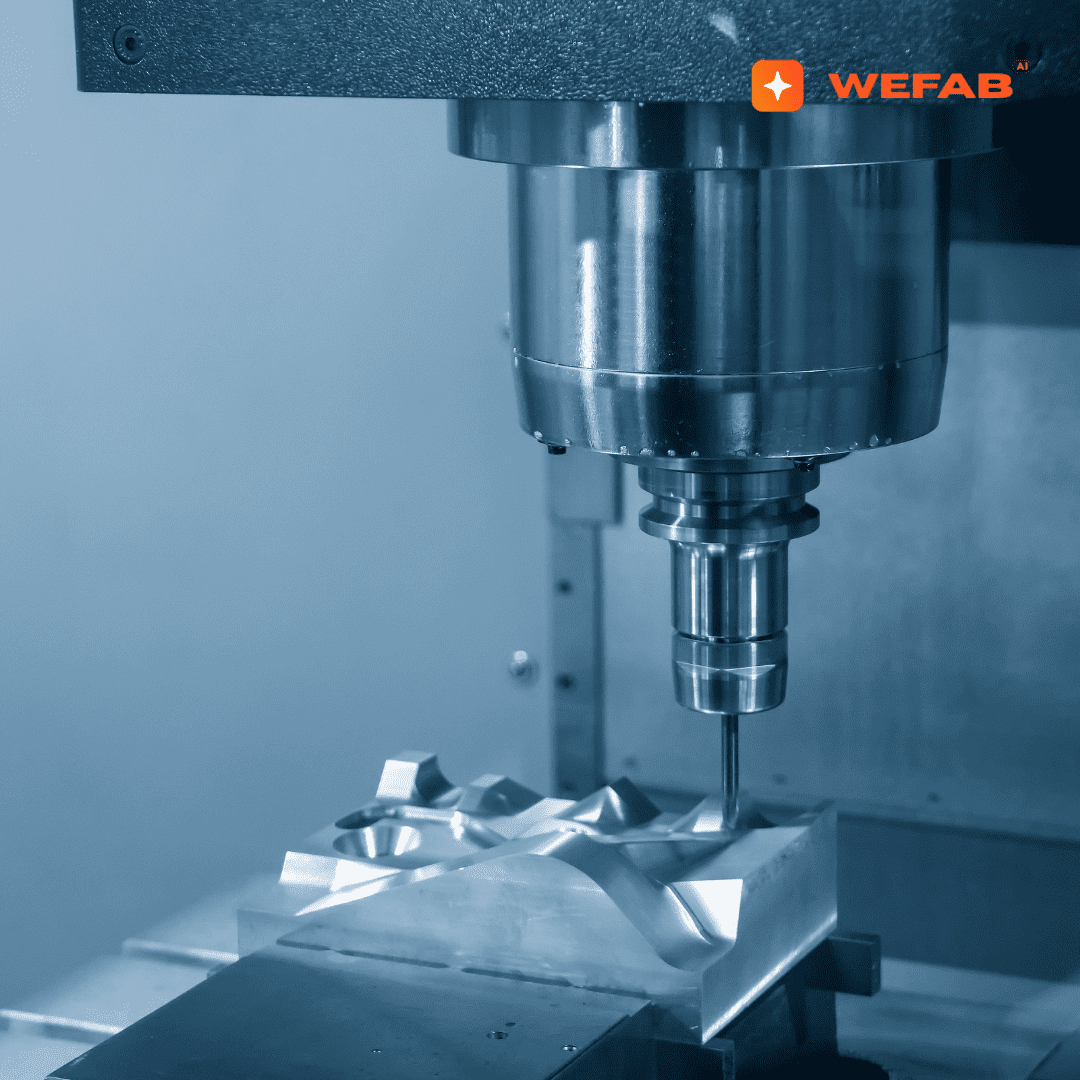

Use Advanced Manufacturing Tech

Contemporary manufacturing tech, such as AI-powered quality control or digital twins, assists in reducing lead times and minimizing mistakes. Say, for instance, AI can identify patterns in tool wear that humans overlook, allowing crews to plan maintenance before issues strike. 3D printing and CNC automation accelerate prototype builds, enabling change testing without major lag or expense. These technologies aren’t just buzz—they enable startups to spot and address hazards before they become problems, ensuring production stays seamless. Wefab’s platform pushes out real-time updates, connecting all stakeholders, so surprises get handled fast.

Assess and Plan for Risks

Risk assessment is non-negotiable. Teams must list out what could go wrong and how to handle it. It’s not enough to plan once. Regular reviews catch changes in supplier risk, pricing, or timelines. Adaptation and fast course correction keep startups ahead of trouble.

Facing Supply Chain Delays or Quality Issues in EV or Robotics Design?

Get expert support from wefab.ai to streamline early supplier engagement, enhance product quality, and reduce rework costs.

Strengthen your design process and accelerate time-to-market!

How Is AI Changing The Way EV Startups Manage Tooling Cost Overruns

AI is transforming how EV startups handle tooling cost overruns. With increasing supply chain complexity and demand for top-notch, affordable products, AI provides tangible, operational value. Its impact is far more than buzzwords, making a tangible, proven difference in how teams plan, build, and manage tools.

Use AI-Driven Solutions to Cut Cost and Errors

AI-powered factory platforms detect waste and defects before they occur. By automating tooling bottlenecks, these systems reduce the time wasted on manual checks and rework. For instance, AI can analyze millions of transactions with near-perfect precision and identify anomalies — like fraud detection, which AI can execute with 99.9% accuracy. The result is direct savings. For EV startups, where margins are wafer-thin, this magnitude of effect can be the difference between crashing and flying.

Automated Manufacturability Checks with AI-Enhanced DFM

AI-powered DFM tools don’t just catch errors—they demonstrate optimal ways to manufacture components prior to tooling investment. By using automated checks to pinpoint design risks, these tools translate into fewer expensive changes after molds or dies are incurred. By simulating and learning from previous projects, the AI can demonstrate if a design is prone to failure, or if an alternative might save time and expense. This type of early vision is crucial for startups dealing with small batch or custom components, preventing late-stage errors that are costly and time-consuming to fix.

Predictive Maintenance and Production Reliability

Unscheduled downtime wrecks schedules and inflates cost. Predictive maintenance, powered by AI, addresses this utilizing real-time data from machines to identify issues before they halt production. For EV startups with narrow launch windows, this translates into more dependable delivery and more efficient capital usage. Another predictive algorithm can reduce diagnostic errors by as much as 85%, avoiding the repair-loop that extends projects. That reliability boost from AI keeps its lines humming and quality high.

Insights from AI Analytics

AI analytics transform data from all your work, tools, and machines into actionable insights. With the right platform, like Wefab AI, startups get dashboards that show real-time tooling performance, flag issues, and guide smarter choices. These intelligence help groups move quickly, modify workflows, and hit goals for cost, speed, and sustainability.

How Does AI Create Opportunities For Growth Beyond Just Saving Money

AI is disrupting the way EV startups consider tooling cost overruns. It’s not just cost—AI creates opportunity for innovation, speed and superior offerings that help a company get a leg up.

Reduce Busywork and Boost Strategy

AI tools can automate boring, repetitive tasks. This allows teams to dedicate more time to planning, design, and addressing the hard things. For instance, taking some of the supply chain or order tracking off their plate allows their staff to focus on what really counts—making parts and launching new vehicles. Over 40% of executives say AI has increased their team’s productivity. That translates to quicker market shift response — and reduced risk of lagging.

AI also assists with intelligent decisions. It can identify what’s effective in a design or where bottlenecks could occur in manufacturing. This feedback loop creates a more intelligent, nimble organization.

Optimize Product Design for Performance

AI can run simulations and test ideas and spot flaws before a part is made. It reduces the danger of costly last-minute modifications. For EV startups, this implies new battery modules or chassis designs can be examined for stress, heat, or fit in hours — not weeks.

These gains come with real costs: the complexity of a good AI model can be 30–40% of a project’s budget. Planning wisely is important. Even so, the end result is products that perform better and get to market quicker.

Stay Ahead in a Rapidly Changing Industry

The EV space is accelerating. More than three quarters of companies employing AI somewhere in their work today. By 2026, 30% of firms will automate over 50% of their network processes. AI-powered chatbots alone increased completed purchases by 25%. For startups, this implies that leveraging AI is no longer a perk — it’s a requirement to remain competitive.

AI-powered recommendations, such as 80% of content viewed on streaming platforms generated by algorithms, demonstrate how intelligent systems can increase engagement and conversion in device purchases.

Integrate AI into Workflows

Plugging AI into your existing workflows can begin small–perhaps automating supplier matching or project updates. Wefab AI is a good example. Its platform matches EV makers to the right vendors, determines precise production specs, and monitors progress — all with AI. This results in less confusion, higher quality and less waste.

Smart integration means teams flow better. Businesses act fast, shift when necessary, and identify opportunities ahead of time.

How Do Expert Technicians Enhance The Effectiveness Of AI For Injection Molding

AI holds immense potential to manage tooling costs for EV startups, but its success hinges on the critical role of skilled humans. Even with advanced software, repair shops rely on technicians who can spot issues, adjust machines, and make informed decisions when data alone isn’t clear. These experts enhance AI’s effectiveness by providing real-time feedback from the shop floor. For example, if an AI flags a mold as faulty but a technician recognizes it needs only a minor tweak, this collaboration saves both time and money.

The Importance of Skilled Technicians

Training is the next vital step to unlock AI’s full potential. As AI tools evolve, employees must continuously upskill through short courses or workshops to master interpreting AI dashboards, responding to alerts, and fine-tuning configurations. Research shows that startups integrating AI achieve better outcomes when teams understand how to work alongside these technologies. Approximately 70% of startups use AI for faster decisions and streamlined workflows, but this success depends on trust and confidence—qualities that grow as employees see AI lighten their workload. Studies suggest certain roles can see a 40% reduction in routine tasks thanks to AI.

Prioritizing Continuous Training

A collaborative culture further amplifies AI’s benefits. When humans and AI interact—sharing insights, highlighting unusual results, and celebrating successes or learning from setbacks—the system becomes smarter over time. Wefab’s approach encourages this dynamic by allowing users to flag issues, suggest improvements, and train the system with real-world shop data. This feedback loop helps prevent errors and catches biases early, which is crucial since unsupervised AI can magnify human mistakes.

Fostering a Collaborative Culture

To maintain a competitive edge, continuous training is essential as AI expands. The demand for new skills—quick thinking, sound judgment, and a clear grasp of AI’s strengths and limits—grows alongside technology. Leaders should foster ongoing discussions on best practices, ethics, and lessons learned, ensuring AI remains a tool that serves humans, not the other way around.

Struggling with Injection Molding Cost Overruns for EV Prototypes?

Optimize your tooling with Wefab’s AI solutions to cut overruns and speed up production.

Discover how we can transform your manufacturing today.

Conclusion

Even minor design or process adjustments can trigger significant cost escalations, placing immense pressure on EV startup teams to mitigate expenses. Hasty, improvised solutions often exacerbate waste, further inflating budgets. However, the intelligent application of AI offers a transformative approach by identifying cost leakages and providing actionable pathways for remediation. While AI enhances decision-making with data-driven insights and optimized options, the ultimate authority remains with human expertise, ensuring a balanced strategy.

This synergy enables startups to scale efficiently, avoiding catastrophic financial setbacks and fostering sustainable growth. True success emerges from the collaboration between sharp human intellect and advanced technological tools, driving innovation in injection molding investments. For those prepared to elevate their operations, explore Wefab.ai and request an immediate quote for injection molding solutions to unlock tailored strategies and maximize your return on investment.