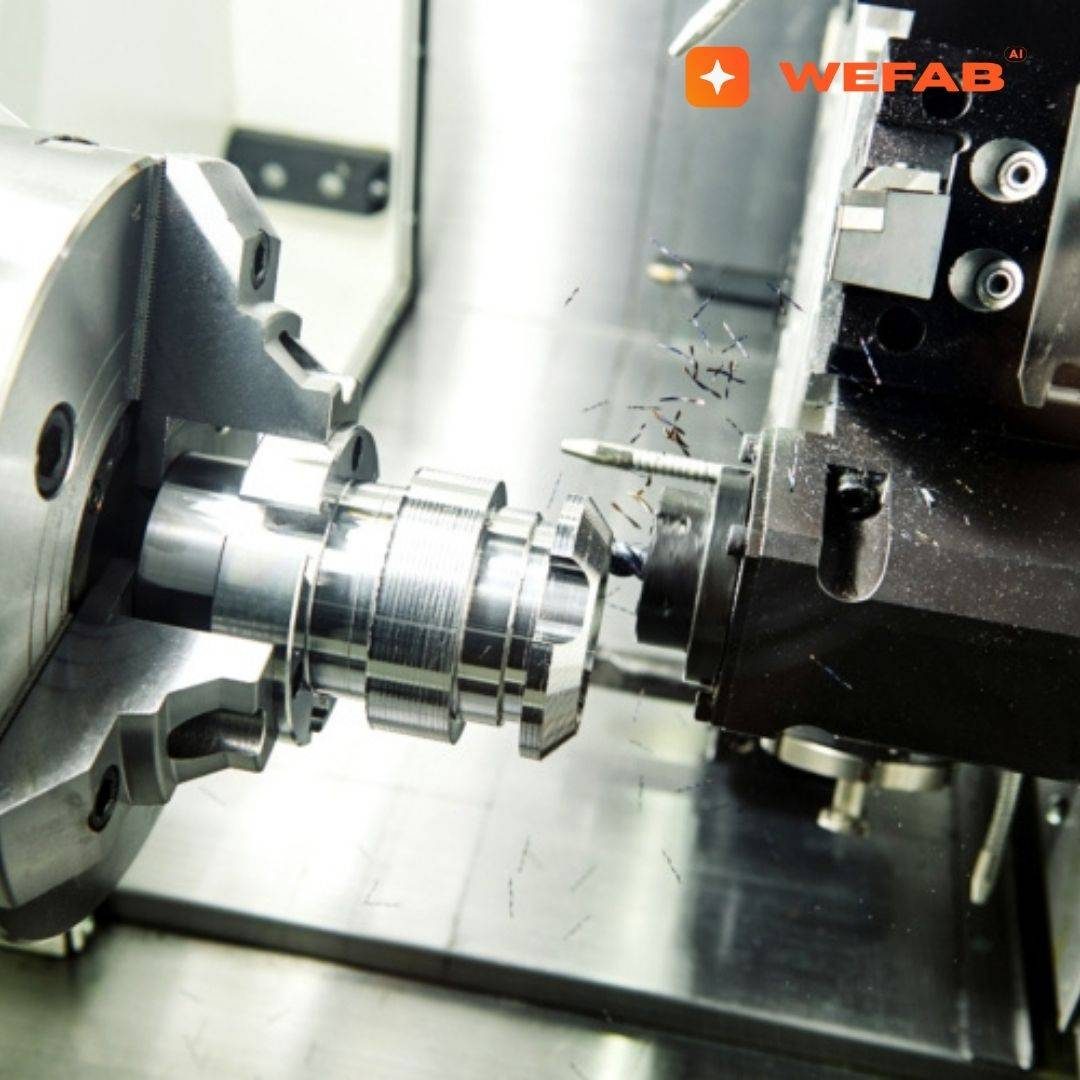

Can robotics manufacturing achieve the precision demanded by today’s stringent standards? Tight tolerance requirements in robotics manufacturing present formidable challenges, demanding exacting precision in component dimensions and shapes to meet rigorous safety, performance, and interoperability standards. Even minor deviations—caused by environmental fluctuations, tool degradation, or material inconsistencies—can disrupt CNC milling, injection molding, or other critical processes, leading to increased waste, prolonged lead times, and elevated costs. These issues strain supply chain managers and engineering teams, who face mounting pressure to maintain consistency while scaling production.

In the following sections, we will explore the root causes and consequences of these tight tolerance challenges, highlighting their impact on robotics manufacturing and the complexities they introduce for operational resilience.

What Are The Fundamental Challenges In Achieving Tight Tolerances In Robotics Manufacturing?

Achieving tight tolerances in robotics manufacturing is fundamental to producing high-precision components, yet it introduces complex challenges at every stage of production. From raw materials to environmental conditions, each element—material properties, design intricacies, process variability, and external factors—can compromise quality, leading to costly rework, delays, and reduced operational efficiency. Below, we explore these challenges with expertise-level insights, detailing their technical implications for robotics manufacturing.

1. Material Instability

Material inconsistencies pose a significant barrier to maintaining tight tolerances in robotics components, such as actuators or sensor housings. Variations in alloy composition, grain structure, or polymer viscosity—often stemming from supplier batch differences—can alter mechanical properties like stiffness or thermal expansion. For instance, a 0.01% shift in carbon content in steel can change its machinability, causing dimensional deviations during CNC milling. Temperature fluctuations during processing exacerbate these issues, inducing unpredictable shrinkage or expansion that misaligns parts, disrupting assemblies and compromising system reliability.

2. Design Complexity

Intricate geometries, common in robotics for lightweight or multifunctional parts, amplify tight tolerance challenges. Features like micro-channels, thin walls, or complex curvatures increase the risk of machining errors, as they demand precise tool paths and minimal deflection. For example, a 0.005 mm deviation in a gear’s tooth profile can cause misalignment in a robotic arm, leading to performance failures. The absence of early collaboration between design and manufacturing teams often results in specifications that exceed practical machining capabilities, necessitating costly iterations or concessions in quality.

3. Process Variables

Manufacturing processes introduce variability that undermines tight tolerance goals, even with standardized designs. Machine setup inconsistencies, such as improper fixturing or calibration drift, can lead to dimensional inaccuracies. Tool wear, a pervasive issue in CNC milling or turning, gradually degrades precision; a worn end mill may deviate by 0.02 mm, pushing parts out of spec. Operator-dependent factors, like manual adjustments or inconsistent inspection protocols, further compound errors, creating unpredictable outcomes that challenge quality assurance in high-precision robotics production.

4. Environmental Shifts

Environmental conditions significantly impact tight tolerance manufacturing, as even minor changes in temperature or humidity can alter material behavior. For instance, a 2°C rise in shop floor temperature can cause a 0.012 mm expansion in a 100 mm aluminum component, exceeding typical robotics tolerances of ±0.01 mm. Humidity fluctuations affect polymers, inducing swelling or warping that disrupts injection-molded parts. These subtle shifts, often undetected without rigorous monitoring, push components out of specification, leading to assembly failures and increased scrap rates in robotics manufacturing.

How Do Micron Level Errors In Robotics Parts Impact Performance Degradation

Even tiny errors of imprecision can have a massive impact along the production chain. In high-velocity domains such as robotics, climate tech, and EV, these close tolerances are more than a technical necessity—they propagate through each step of the process from design to application.

Performance Degradation

Micron-level errors in parts can cause robots to lose repeatability or accuracy. When a robotic arm joint is only 0.02 mm off, its end-effector could miss or drop, causing product defects or downtime. Over time, even tiny misfits add up to added friction and vibration, accelerating wear on gears or bearings. This reduces the robot’s longevity and increases the likelihood of malfunctions. Periodic monitoring of critical parameters—such as backlash, straightness, or positioning error—prevents these problems from escalating into catastrophic breakdowns and expensive repairs.

Assembly Failures

Loose tolerances result in misaligned holes, wobbly surfaces or skewed mounts. This can prevent components from aligning properly, which in turn bogs down the entire manufacturing line. In robotics, this could translate to a sensor mounting bracket that moves out of position, resulting in system faults. Accuracy in every piece is what allows entire systems to click together quickly, reduce mistakes and increase throughput. Testing each subassembly at the outset, well before final build, minimizes the risk of last-minute shocks.

Escalating Costs

|

Source of Cost |

Cost Impact per Batch (USD) |

Example Scenario |

|---|---|---|

|

Rework |

2,000–10,000 |

Machining out-of-spec housings |

|

Scrap |

1,575–5,250 |

Discarding mismatched connector sets |

|

Downtime |

3,150–21,000 |

Line halt from failed actuator assembly |

|

Warranty/Returns |

2,625+ |

Returned robots from field failures |

Inefficiency from bad fits is more work, longer cycle times and more scrap. Every additional move to repair or swap out a defective piece cascades, cutting into margins and extending delivery schedules. I

Customer Satisfaction and Brand Reputation

Missed tolerances damage trust in the long run. End users, on the other hand, want products to work right, every time. Every failure erodes that confidence. Even a couple of bad parts can reverberate through the online review or lost reorders.

Why Traditional Quality Control Falters Robotics Production Demands

Tight tolerances raise the quality bar in hardware manufacturing. Traditional methods—manual inspections, sample checks, and post-process audits—fall behind the speed, scale, and complexity of today’s production demands. This is particularly true in climate tech, robotics, and EV, which require exactness and traceability.

Key limitations of traditional quality control:

- Manual inspection is tedious, subject to human error, and not scalable.

- Delayed feedback increases scrap rates and rework costs.

- Limited visibility across distributed supply chains.

- Data is often siloed, incomplete, or hard to trace.

- Difficulty adapting to rapid design or volume changes.

Reactive Nature

Most old-fashioned quality control is reactive. Teams depend on after-the-fact inspections, which tend to identify defects only after they’ve already propagated downstream or arrived at customers. This generates a late discovery, expensive-fix cycle — particularly for products with sub-millimeter tolerances.

By waiting until defects appear, companies lose time and miss early warning signals. This lag adds to waste and cost, while causing root cause analysis more difficult. Proactive quality management flips the script: by embedding real-time sensors and using in-process monitoring, issues can be caught as soon as they emerge.

Scalability Issues

Manual quality checks fail to scale. As production increases, it becomes difficult to keep quality control consistent over several lines or vendors. That typically translates to greater error rates and inconsistent quality – particularly in high-mix, low-volume runs typical of hardware startups.

Data Blindspots

Old systems overlook essential data. Manual logs or spot checks don’t capture enough detail for deep analysis, leaving gaps in understanding process health. These blindspots curtail leaders’ decision-making.

When data is incomplete or difficult to connect, it’s simple to overlook patterns that cause defects or bottlenecks. Constructing a consolidated, digital quality record—connected to ERP and MES systems—provides a complete picture of performance. With sophisticated analytics, trends surface directing more intelligent choices and improved results.

How AI Solutions Ensure Component Precision in Manufacturing

Making tight tolerances is no longer just about skilled labor and cutting edge machines. AI-powered tools are now assisting manufacturers to meet these rigorous requirements, transforming once-bottlenecks into opportunities to increase quality, reduce production time, and lower costs. These solutions enable teams to discover and address issues before they escalate, pivot in real time to shifting environments, and maintain quality at every stage. This approach is rooted in business impact and technical rigor and cultivates faith in AI as a collaborator, not an infatuation.

Predictive Quality

Machine learning allows teams to identify threats to component quality well before final inspection — moving quality assurance from reactive to preemptive.

-

Sensors generate a mountain of data both from machines and initial production runs.

-

Algorithms compare patterns to identify irregularities — like tool wear or material changes — that might lead to glitchy parts.

-

Alerts instigate behavior, such as tweaking parameters or pulling questionable lots, to avoid expensive scrap or reprocessing.

-

The feedback from each cycle updates the model, making predictions more precise with each iteration.

Predictive analytics is most effective when seamlessly integrated into daily workflows, rather than tacked on as an auxiliary tool. By building models that learn from every new batch, teams keep ahead of shifting tolerances, even as designs or suppliers change.

Adaptive Machining

AI can dynamically optimize machining parameters—feed rate, tool speed, depth—to maintain parts within spec.

Real-time feedback loops allow machines to react immediately to variations such as tool dulling or material inconsistencies. That translates into less downtime, less scrap and more efficient use of raw materials. These adaptive systems do more than just slash waste — they promote sustainability by minimizing unnecessary power and material consumption. Employees will have to learn to read AI cues and respond quickly, translating information into real behavior on the factory floor.

Smart Inspection

Artificial intelligence-backed inspection systems, such as computer vision cameras, scan every component for defects with a speed and precision that manual inspections simply can’t compete with. Automated inspections reduce human error, capture granular defects, and liberate employees for more valuable tasks. With computer vision quality checks, even microscopic imperfections are detected fast, reducing the risk of error creep. With platforms like Wefab AI, continuous monitoring helps teams meet tolerance targets all day, every day.

Struggling with Tight Tolerance Delays in Robotics Production?

Enhance precision with wefab.ai’s AI solutions—request a custom quote to optimize your manufacturing process and reduce costs today!

Discover how we can transform your manufacturing today.

How Does Human AI Collaboration Achieve Tight Tolerances In Manufacturing Processes

Achieving tight tolerances in robotics manufacturing demands a seamless collaboration between human expertise and AI-driven capabilities. This partnership empowers teams to meet stringent specifications, adapt to rapid technological advancements, and maintain operational efficiency in high-precision environments. By combining human ingenuity with AI’s analytical power, robotics firms can address complex challenges, from material variability to process optimization, ensuring consistent quality and scalability.

Empowering Engineers with Data-Driven Precision

AI enhances engineers’ ability to meet tight tolerances by processing vast datasets from CNC milling, injection molding, and quality inspections to identify subtle deviations invisible to manual analysis. For instance, machine learning algorithms can detect a 0.005 mm variance in a robotic actuator’s dimensions by analyzing real-time sensor data, enabling preemptive design adjustments to prevent assembly failures.

AI-driven platforms further validate manufacturability, predicting stress points or thermal distortion risks with finite element analysis (FEA) integration, reducing scrap rates by up to 15% in high-precision contexts. Services like those from wefab.ai streamline this process by connecting engineers with vetted suppliers and providing real-time project updates, fostering a collaborative ecosystem that accelerates iterative design improvements and ensures compliance with tolerances as tight as ±0.01 mm.

Upskilling Operators for Advanced Process Control

Operators must master AI-integrated systems to maintain tight tolerances on the shop floor, where even a 0.02 mm deviation can render a component unusable. Comprehensive training programs on AI-enabled control systems, such as those monitoring spindle vibration or coolant flow, equip operators to detect anomalies in real time, preventing production halts.

Fostering Innovation Through Collaborative Experimentation

The human-AI partnership drives innovation by embedding AI experimentation into manufacturing workflows, enabling rapid prototyping and process optimization. Cross-functional teams, combining engineers, operators, and supply chain planners, leverage AI to simulate production scenarios, identifying optimal machining parameters that minimize cycle times while achieving tolerances within ±0.005 mm. Strategic R&D investments, supported by AI-driven predictive modeling, have reduced lead times by 25% in robotics firms by anticipating material behavior under varying conditions. Services from wefab.ai enhance this innovation by facilitating seamless supplier coordination and real-time performance tracking, allowing teams to test novel designs and adapt to market shifts without compromising precision or efficiency.

Facing Precision Challenges in Robotics Manufacturing?

Get expert support with wefab.ai—contact us today to discuss tailored AI solutions and improve your component accuracy!

Discover how we can transform your manufacturing today.

What Are The Key Strategies For Effectively Implementing AI To Ensure Precision In Production

Artificial intelligence (AI) revolutionizes the achievement of stringent tolerance targets in robotics manufacturing by integrating precision, speed, and real-time data analysis. This synergy streamlines collaboration across design, manufacturing, and quality control, enabling supply chain managers and engineers to enhance reliability and traceability. Below are key strategies for implementing AI effectively, with expert-level insights to ensure precision in robotics production.

Initiate Pilot Projects for Controlled Implementation

Launching small-scale pilot projects minimizes risk while testing AI’s efficacy in addressing specific manufacturing challenges. For example, deploying AI to analyze sensor data from CNC milling can detect dimensional drifts within 0.005 mm, or optimizing toolpath planning for 3D printing can reduce cycle times by 10%. These targeted pilots yield measurable outcomes, fostering team confidence and providing data-driven insights for gradual expansion to additional processes or facilities.

Centralize Data for Seamless Integration

AI’s effectiveness hinges on high-quality, aggregated data from CAD systems, shop floor equipment, inspection tools, and supplier reports. A centralized data hub enables benchmarking of production batches, trend identification, and rapid issue resolution.

Consistent data formatting—using standardized labels and metric units—ensures accuracy, while cloud-based systems facilitate real-time access for distributed teams, enhancing collaboration and minimizing integration errors.

Measure and Refine Performance Metrics

Establishing clear success metrics, such as defect rates, rework hours, or energy consumption, is critical for evaluating AI’s impact. Regular reviews of these metrics—e.g., a 15% reduction in defect rates—allow teams to adjust AI models when new challenges arise. Transparent reporting to stakeholders, from operators to management, builds trust and supports continuous improvement. Wefab.ai leverages this approach, enabling its teams to achieve first-pass precision in robotics and climate tech manufacturing.

Conclusion

Tight tolerance requirements are the cornerstone of robotics manufacturing, where even a 0.01 mm deviation can disrupt component fit, halt production lines, and compromise system performance. Conventional quality control methods often fail to detect subtle variances caused by material inconsistencies or environmental shifts, leading to increased scrap rates, extended lead times, and eroded operational efficiency. By integrating artificial intelligence (AI), robotics manufacturers can achieve unparalleled precision through real-time data analysis, identifying dimensional drifts and enabling rapid corrections. This synergy of human expertise and AI-driven insights empowers teams to reduce waste by up to 15%, enhance first-pass yield, and streamline inspections, ensuring compliance with tolerances as stringent as ±0.005 mm. Wefab.ai supports this transformation by connecting its teams with vetted suppliers and providing real-time project updates, fostering resilient operations. To strengthen your manufacturing precision, visit wefab.ai to request an instant quote and elevate your production outcomes.