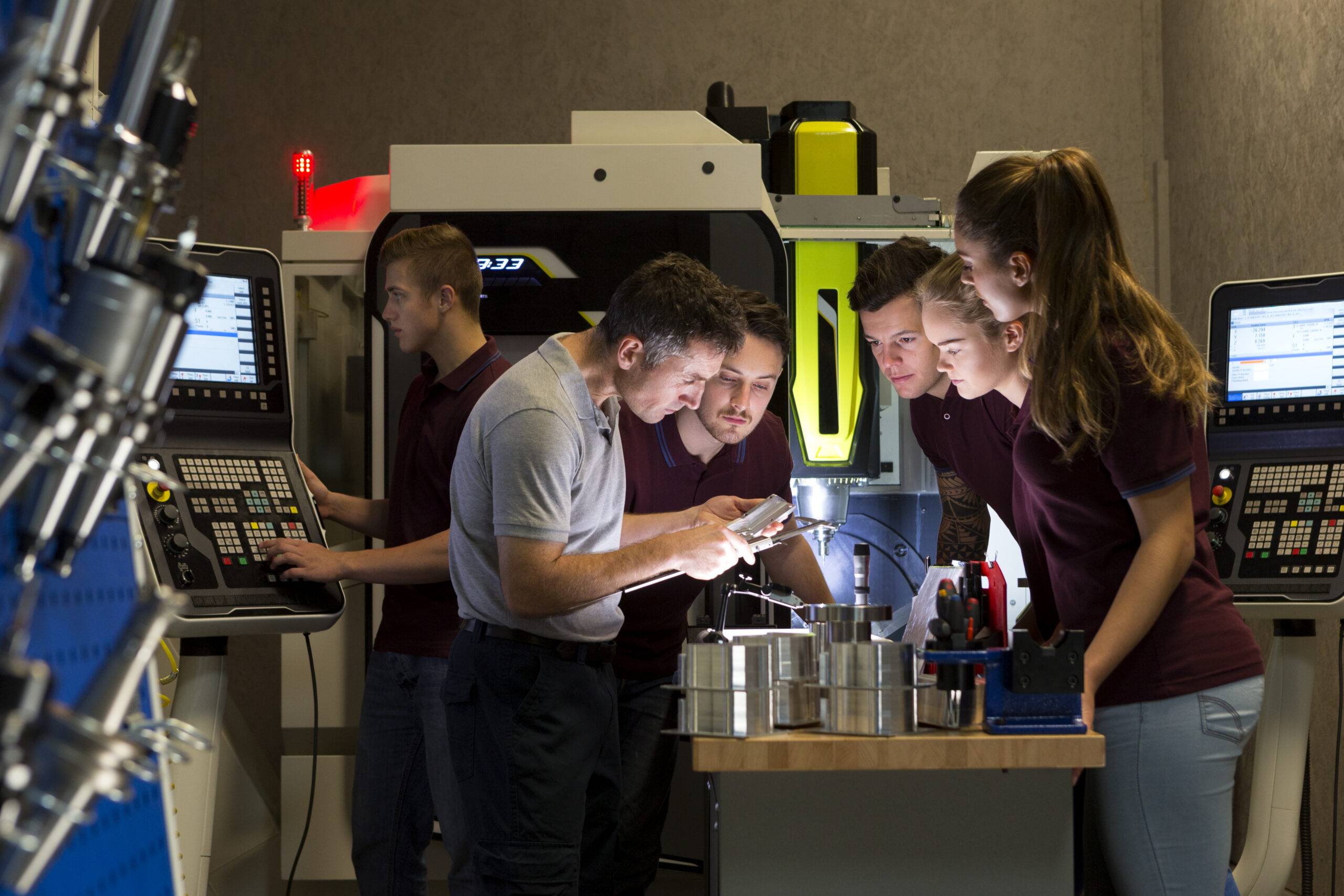

Your AI-First Manufacturing Partner

Hardware innovation requires manufacturing excellence. From custom components to end-to-end production, our AI-enhanced approach delivers precision parts with unmatched quality and efficiency.

End-to-End Production

From design to delivery, we manage your complete manufacturing journey with AI-optimized processes that ensure quality, efficiency, and transparency.

Small Batch Production

When you need individual components or small batches, our AI-enhanced approach delivers the exact parts you need without minimum order quantities or excessive lead times.

Manufacturing Expertise That Delivers Results

Working with a manufacturing partner who understands your product needs makes all the difference.

Decades of Combined Experience

Our team brings 30+ years of expertise in machine design, automotive engineering, and precision manufacturing

Industry-Specific

Knowledge

Deep understanding of Climate Tech, Robotics, EV, and Consumer Product manufacturing challenges

Methodological

Approach

Using the Theory of Constraints, we optimizes manufacturing with proven methods for efficiency and precision.

AI-Enhanced

Processes

Technology that augments human expertise, increases efficiency 24/7, and reduces human errors for superior manufacturing outcomes.

Manufacturing Approach Built For Innovation

We help hardware makers win. We blend hands-on experience with best practices and AI to create results others can’t match.

Expert Design Analysis

Our engineering team and AI platform thoroughly analyze your design for manufacturability

Strategic Planning

We develop a comprehensive manufacturing strategy optimized for your specific requirements

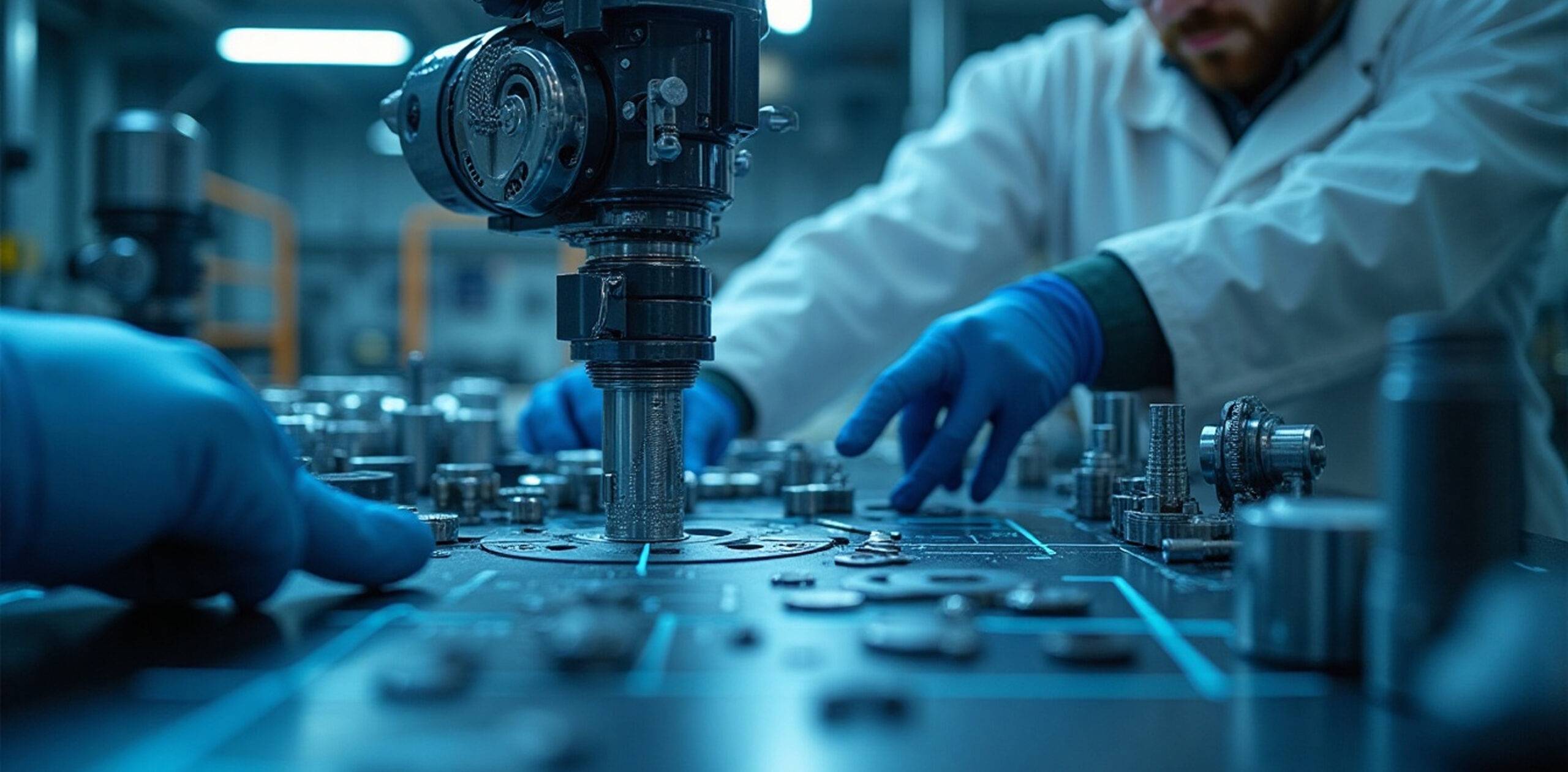

AI-Optimized Production

Our engineering team and AI platform thoroughly analyze your design for manufacturability

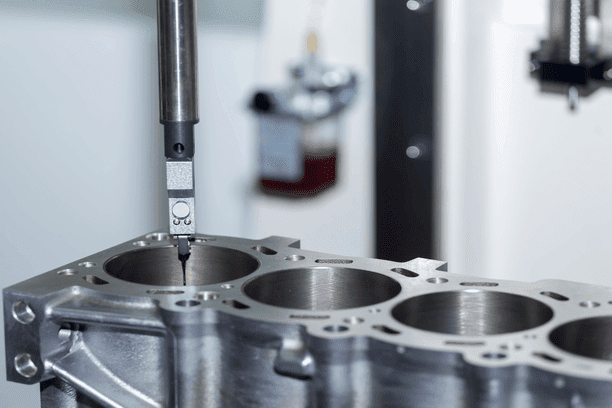

Rigorous Quality Control

Precision components built right. Every time. We prevent defects through disciplined processes, not just detection.

On-Time Delivery

Secure packaging and reliable shipping to your facility

Specialized Expertise Across Industries

Not seeing your industry listed? No problem— Our capabilities extend well beyond these sectors

Climate Tech

Precision components for sustainable energy systems, carbon capture technologies, and environmental monitoring.

Electric Vehicles

Critical components for EV powertrains, battery systems, charging infrastructure, and control electronics.

Robotics & Automation

Specialized parts for robotic systems, sensor arrays, control mechanisms, and automation equipment.

Consumer Hardware

End-to-End Manufacturing Solutions

Contract Manufacturing

Full production management from design through delivery:

- Design for manufacturing

- Prototyping with scale in mind

- Batch production

- Test & Certification

- Production at scale

- Continuous improvement

Custom Manufacturing

Precision parts and small batch production:

- One-off components

- Small batch production (5-500 units)

- Rapid turnaround

- Design for manufacturability

- Comprehensive quality verification

Manufacturing Excellence, Enhanced by Technology

Our proprietary AI platform supports our expert team throughout the manufacturing process

Design for Manufacturability

Design for Manufacturability

The AI optimizes your design for manufacturing, balancing cost, efficiency and quality.

Process Optimization

Process Optimization

AI creates an optimum process for best results, using theory of constraints for best utilization of resources.

Vendor Allocation

Vendor Allocation

Project Monitoring

Project Monitoring

"We've developed our AI platform to enhance manufacturing decisions, not replace human expertise. The result is a powerful combination that delivers superior results."

Specialized Expertise Across Industries

Not seeing your industry listed? No problem— Our capabilities extend well beyond these sectors

Climate Tech

Precision components for sustainable energy systems, carbon capture technologies, and environmental monitoring.

Electric Vehicles

Critical components for EV powertrains, battery systems, charging infrastructure, and control electronics.

Robotics & Automation

Specialized parts for robotic systems, sensor arrays, control mechanisms & automation equipment.

Consumer Hardware

The Wefab Advantage

AI-Enhanced Manufacturing

Technology that optimizes production without sacrificing human expertise

Methodology-Driven Approach

Theory of Constraints implementation that maximizes efficiency

Complete Transparency

Real-time visibility into your manufacturing process at every stage

Engineering Excellence

Team with decades of manufacturing experience across multiple industries

Quality

Commitment

Rigorous quality systems that ensure precision and consistency

Delivering Results for Innovative Companies

Company Name A

Helped a climate monitoring company reduce their development timeline by 35% through AI-optimized manufacturing and design improvements.

“Wefab’s combination of manufacturing expertise and AI technology helped us bring our product to market months ahead of schedule.” – Engineering Director, ClimateMonitor

Company Name A

Delivered precision components for a robotic control system with complex geometries that three previous manufacturers couldn’t produce.

“When other manufacturers said it couldn’t be done, Wefab found a way. Their engineering team and AI system developed a manufacturing approach that delivered flawless parts.” – CTO, Robotics Innovator

Trusted By Innovative Hardware Companies

EV and Automotive

Industrial Automation

Climate Tech

Consumer Electronics and Appliances

Robotics

Trusted By Innovative Hardware Companies

Unlock Your

Manufacturing Breakthrough

Transform Your Manufacturing Experience

Whether you need comprehensive contract manufacturing or precision custom parts, we’re ready to help.

Contract Manufacturing

Ready to discuss your end-to-end manufacturing needs? Our team will work with you to develop a comprehensive production plan.

Initial Consultation

We’ll discuss your project requirements, volumes, and timeline.

Design Review

Our team will analyze your designs for manufacturability and cost optimization.

Proposal & Planning

We’ll provide a detailed manufacturing proposal and production plan.

Custom Manufacturing

From single units to small batches. We build exactly what you need, when you need it, without minimum order requirements.

Design Submission

Submit your CAD files and project requirements for review.

Feedback & Quote

We’ll provide design feedback and a detailed quote within 48 hours.

Prototype Production

After approval, we’ll produce your prototypes with quality verification.

Common Questions

What makes your AI-native approach different?

Our AI-native approach means we’ve built intelligent technology into every step of the manufacturing process, from design analysis to production optimization. Unlike traditional manufacturers who rely solely on human expertise or digital platforms that simply match customers with suppliers, we combine the best of both worlds: AI technology that enhances manufacturing decisions and a team of experienced engineers who ensure quality and precision.

Can WeFab.ai handle small-batch production for prototyping?

Yes! We specialize in flexible small-batch production, making it easy to prototype and scale your consumer tech innovations with our in-house manufacturing capabilities.

What manufacturing capabilities do you offer?

We provide precision CNC machining, sheet metal fabrication, 3D printing, injection molding, and AI-driven process enhancement across design & manufacturing stages. Our services support rapid prototyping to high-volume production for multiple industries.

How to book a free consultation, and how we take it from there?

Book a free consultation by filling out the form with your details and preferred time. We’ll discuss your needs, provide expert insights, and follow up with a tailored plan to start your project.